Delfland facility reports 98% denitrification efficiency

By J W Wouters, P de Been

Municipal wastewater treatment plants in the United Kingdom and Europe must remove total nitrogen to meet European Union water quality regulations, especially in dedicated sensitive areas. Consequently, biological denitrification will be increasingly integrated in treatment facilities.

The Astrasand® moving bed biofiltration, a tertiary treatment process used successfully in industrial and municipal sectors, has been in continuous operation at one of Europe's largest wastewater treatment plants since mid-1999. The Netherlands' company Paques bv developed the process. The Water Authority of Delfland reports that its De Groote Lucht wastewater treatment plant in Vlaardingen, achieves high denitrification efficiencies resulting from highly efficient filter control. The process further reduces both total suspended solids (TSS) and chemical oxygen demand (COD), producing good effluent quality. The process configuration based upon partial treatment proved to be effective for achieving the annual average consent level for N-total, being 10 mg/l.

The De Groote Lucht process scheme basically consists of two-stage aerobic treatment for full biological oxygen demand (BOD) and ammonia (NH4+) removal, followed by partial biological denitrification. Consent levels for total nitrogen (<10 mg/l N) are related to annual average levels, so it is not necessary to design the tertiary process for full flow to treatment (FFT) conditions. The design capacity is based upon 3,600 m3/h, which is 30% of FFT. Approximately 75% of the plant's feed flow is biologically denitrified.

Tertiary treatment process

The post-settled effluent is fed into the pump pit after six-mm drum screens. The water is pumped into the Astrasand moving bed filter, which consists of six units, each equipped with a bed volume of 162 m2. Filtration rates vary in between 2.5 and 15 m/h, with a design Nox-N conversion rate of 1.8 kg/m3/d. In the feed of each unit methanol is dosed proportional to flow and feed NOx-N.

Within the filter anoxic conditions will prevail, enabling the denitrifying biomass to grow on top of and in between the sand grains. The water flows in upward direction through the filter bed, while NOx-N is converted and suspended solids are retained. The produced N2 gas will migrate through the filter and be released at the top.

As the filter sand is rinsed continuously using an airlift and washer assembly, a steady state is created. The filter sand moves downward slowly, towards the bottom, using an airlift in the centre of the filter. In the airlift the sand is continuously transported to the washer section at the top of the filter and rinsed finally before it is released back onto the top of the sand bed. A continuous flow of wash water is released, containing the excess biomass and the retained suspended solids. The filtrate is discharged via the effluent outlet channel onto surface water.

In order to achieve an optimal filter performance, a process control system was developed to maintain high biological activity within the filter at varying feed conditions. The control system is based upon a continuous adjustment of the sand movement and washing rate, focussing upon a fixed volume of active biomass present in the filter bed.

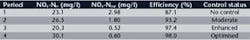

In Table 1, the net effect of this control system is illustrated in terms of denitrification efficiency. The optimised control system helps obtain a 98% denitrification efficiency, and high efficiencies for suspended solids removal.

Biofilter performance data

Typically, NOx-N feed levels of 15-25 mg/l are reduced to filtrate levels of 0-3 mg/l N. Furthermore, the process control guarantees an overall COD decrease over the biofilter of 10%. Typical filtrate suspended solids levels are below 5 mg/l.

Specific methanol consumption and biomass growth have been determined based upon actual methanol consumption and mass balances over the biofilter plant. Specific methanol consumption is found to be 3 mg CH3OH per mg of NOx-N removed, while biomass growth is 1.3 mg per mg NOx-N removed, equal to 0.2 mg/mg COD consumed.

Authors' Note

J. W. Wouters is the project director for Paques bv, Balk, The Netherlands. P. de Been is the manager of the process area south of the Water Authority of Delfland, The Netherlands. For more information, contact the author at Email: [email protected]