Firm develops Innovative Approach to treating oxidant-laden residual streams

Perchlorate, arsenic and high levels of TDS in groundwater of the U.S. Southwest creates challenges for treating potable water that are complicated by the presence of silica and sulfate. A fixed-bed bioreactor proved the solution for a Carollo Engineers pilot study in Salt Lake County, Utah.

Magna Water Company, which serves potable water to approximately 28,000 customers in the northwest section of Salt Lake County, Utah, USA, is partially supplied by groundwater that’s impacted by perchlorate, arsenic, and total dissolved solids (TDS). A six-month pilot study conducted by Carollo Engineers in 1999-2000 showed that due to the presence of high silica and sulfate levels in the groundwater, electrodialysis reversal (EDR) would be the most feasible treatment alternative for Magna. EDR is a separation-based process in which an electrical potential drives charged species (e.g., perchlorate, arsenic, TDS) across ion-selective membranes, thereby removing them from the raw water.

Residuals Concerns

EDR generates a contaminant-concentrated residual stream that must be treated prior to disposal, as perchlorate cannot be discharged to the sewer. Historically, high-strength perchlorate-laden streams have been treated in dedicated biological reactors that convert perchlorate to innocuous chloride and oxygen.

Degradation kinetics of these systems, however, are generally slow (typical required contact times are ~24 hours), associated microbial communities are sensitive to changes in salinity, and high concentrations of a substrate (i.e., bacterial food) such as ethanol must be added to the system. In other words, these systems require large reactor volumes, lack robustness and exert high consumable costs.

Innovative Treatment

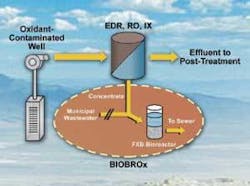

A novel approach to treating perchlorate-laden residuals streams, developed by Carollo Engineers, involves blending the residuals stream with municipal wastewater followed by treatment in a fixed-bed (FXB) bioreactor (Biodestruction of Blended Residual Oxidants or BIOBROx). The process eliminates perchlorate (or any other oxidant such as nitrate, bromate, or selenate) from the residuals stream prior to sewer discharge.

In effect, blending the residuals stream with municipal wastewater decreases the DO concentration and salinity of the untreated stream (i.e., increases degradation kinetics) and eliminates the need to add substrate or a bacterial seed to the bioreactor system. Resulting reactor volumes and consumable costs are minimized and process stability improves. Based on this treatment concept, Carollo submitted a patent application for the BIOBROx process, which is currently pending.

Bench-Scale Testing

As part of AwwaRF Project 2859 (Innovative Alternatives to Minimize Arsenic, Nitrate, and Perchlorate Residuals), a three-month bench-scale study was performed to investigate the feasibility of the above treatment concept. Perchlorate-spiked wastewater from the Magna Water District was used to biologically acclimate the activated carbon in a 2-inch diameter FXB bioreactor.

Seeded only with microorganisms indigenous to the raw wastewater, the bioreactor demonstrated efficient perchlorate removal while using only background organics as substrate. Perchlorate removal to below detection (8 mg/L) was achieved and sustained at empty bed contact times (EBCTs) as low as 30 minutes.

While these data were promising, additional research was required to evaluate process performance when a perchlorate-laden residual stream was blended with the wastewater prior to treatment in the fixed-bed bioreactor.

Pilot Testing

The U.S. Environmental Protection Agency funded a seven-month pilot study at Magna’s Barton Well Field in 2004-2005 to demonstrate the efficacy of the BIOBROx process for removing perchlorate from an EDR concentrate stream. An EDR pilot plant was operated to remove perchlorate, arsenic, and TDS from groundwater, and the resulting concentrate stream was blended with municipal wastewater and treated in a fixed-bed bioreactor.

The data showed that using an EBCT of 10 minutes and a 1.5:1 wastewater flow to EDR concentrate flow blend ratio, sustained perchlorate removal to below detection was achieved in the fixed-bed bioreactor. The associated required reactor volume would be a small fraction of the volume required by “conventional” biological residuals treatment systems.

The results of pilot testing are summarized as follows:

- Average feed and effluent nitrate concentrations were 40 mg/L and < 5 mg/L, respectively.

- Approximately 50% of the feed biochemical oxygen demand (~70 mg/L) was removed across the FXB bioreactor.

- Perchlorate removal performance wasn’t impacted by backwashing episodes, a two-week system shutdown, diurnal variations in wastewater characteristics, or cold weather temperatures (~14°C).

Full-Scale Facility

Based on success of the pilot-scale study, the Magna Water Company has chosen to build a 5.0-mgd EDR + BIOBROx facility to treat its groundwater. Design of the facility is scheduled to be completed in spring 2007, after which time construction will begin.

Significance

The need for long residence times, specialized microbial inocula and high concentrations of exogenous substrate limit the applicability of existing processes used to biologically stabilize concentrated oxidant residuals. This work has shown that the fixed-bed bioreactor process provides an efficient alternative that can be considered for post-treatment of separation-based oxidant treatment processes such as EDR, ion exchange, or reverse osmosis.

Autphor’s Note:

Jess Brown, Ph.D., is the Carollo Engineers Research Group manager and one of the firm’s biological drinking water treatment experts. He has eight years of experience in water and wastewater treatment, specializing in treatment processes and applied research. Contact: [email protected]