FlooBed bioreactor improves biological treatment process

A Polish paper mill benefits by augmenting activated sludge processing with EIMCO bioreactors to meet stricter EU wastewater standards.

The FlooBed® bioreactor, from EIMCO Water Technologies, is a Suspended Carrier Biofilm Process (SCBP) developed especially for industrial wastewater treatment. It’s used to significantly increase the capacity and performance of existing biological treatment systems, but is also suitable for covering the total wastewater treatment.

Biological Treatment Plant Upgrade

In Poland, Mondi Packaging Swiecie - one of the largest pulp and paper mills in Europe - had to increase the performance of its existing wastewater treatment plant in order to meet the new strict environmental demands.

The upgrade was done by installing two FlooBed bioreactors, each with 106,000 ft3 (3,000 m3) in available process volume, in front of an existing activated sludge basin. Half of the reactor volume was filled with bioreactor floating carrier material. Most of the microbes, which perform the purification, grow attached on the surface of these carrier elements. Blocking problems faced with the traditional attached growth processes are avoided in this process thanks to the efficient mixing of the carrier elements. Sufficient mixing is achieved with specially designed bottom aeration system.

Because the treatment processes in the Swiecie mill are operated in series, each biological step is operating at specific conditions to decrease selected organic compounds. In the first reactor, the main part of the easily biodegradable compounds is reduced. In the second reactor, the degradation of difficult compounds to more easily biodegradable components continues. In the third step, the activated sludge basin, the remaining biodegradable compounds are degraded and the sludge quality improved. After this, the sludge is separated in the secondary clarifiers and clarified water is led to the nearby Vistula River.

Aiding Existing Sludge Systems

In contrast to traditional activated sludge processes most of the microbes grow as biofilm on surface of the freely moving carriers. The plastic carrier elements inside the bioreactor have a large surface area and a structure which is optimized to protect the biofilm from abrasion. This allows a high amount of biomass inside the reactor and the needed reactor size can be kept smaller. Savings in civil work costs are remarkable with this process.

Carriers are made of plastic, and their density is slightly lower than that of water. As such, they can be easily mixed throughout the aeration system, which covers the entire reactor bottom. The process doesn’t require backwashes, which was typical for conventional biofilm processes and took up a lot of energy in addition to interfering with the process. Compared to conventional methods the FlooBed bioreactor also tolerates higher variations in water quality and flow and still maintains its high treatment efficiency.

COD, BOD, SS Reductions

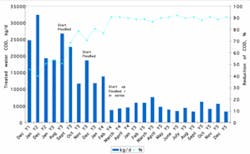

Wastewater flow to the treatment plant is normally about 11,000 gpm (60,000 m3/d) and inlet COD and BOD concentrations 920 and 400 mg/L, respectively.

After the upgrade, COD, BOD and SS reductions over the whole treatment plant have been 90, 95 and 90 %, respectively. Today, the discharge, 4 kg COD per metric ton of produced pulp, is one of the lowest in Europe and well below the future goals for the lower BAT values specified by European Union IPPC Bureau.

In 2003, the company was named the winner of the Swedish Baltic Sea Water Award for its efforts to reduce pollution to the Vistula River.

Author’s Notes:

Formerly of Turku, Finland, Ari Ketonen is product manager for Industrial Water Management at EIMCO Water Technologies, a Salt Lake City, Utah, USA-based unit of Canada’s Groupe Laperrière & Verreault Inc. (GLV). As GLV’s Water Treatment Group, it unites the following brands: Eimco, Dorr-Oliver, Brackett Green, Jones & Attwood, Copa, Enviroquip, Wemco and Caird & Rayner Clark. Contact: +801 526-2161, [email protected] or www.glv.com