The Case for Wastewater Reuse Using UV Disinfection

A planned community north of Phoenix, Arizona, USA, an agricultural area in southern Spain known as “the vegetable garden of Europe”, and a rural town between Sydney and Canberra, Australia, choose alternative treatment technology from Berson UV-techniek to extend their water supplies.

By Sjors van Gaalen

The ultraviolet (UV) light disinfection industry has experienced tremendous growth over the last 20 years, particularly in Europe, the United States and Southeast Asia. Development of new UV technologies over this period is a perfect example of an industry investing to meet market demand – in this case for an effective, low cost and environmentally friendly way to disinfect wastewater for reuse.

Acceptance of UV disinfection at wastewater plants treating almost four billion liters daily is proof UV is no longer an “emerging” technology, but rather an accepted technology to be used routinely by engineers to safeguard human health and alleviate environmental pressures.

Wastewater reuse has been practiced in various forms for decades, with the USA leading the way in reuse research. Once a major issue almost exclusively in arid parts of the southern USA, southern Europe, the Middle East, Australia and many parts of Asia where chronic water shortages are driving investment in reuse technology, interest is now spreading due to population growth, urbanization and anticipated effects of global warming.

Technology Advancements

Use of computational fluid dynamics (CFD) modeling has vastly improved UV equipment manufacturers’ ability to predict with confidence the level of treatment required for wastewater using their proprietary equipment. All manufacturers will soon use this tool to optimize dose delivery of their UV reactors and minimize energy costs. Also, as manufacturers develop and improve optimized reactors, they’ll be able to validate designs using recognized validation protocols.

Conventional UV lamp technology also are expected to improve over the coming years, with medium pressure lamps continuing to see gains in energy efficiency, lamp life and power density, and quartz coating techniques extending lamp life to well over 12,000 hours.

Concerns

A major concern to the UV industry is the issue of reactivation – the apparent ability of some microorganisms to repair damage done to their DNA by UV, reactivating their ability to reproduce and infect. DNA repair can occur in a closed (dark) system, but is more likely in open systems under direct sunlight (photoreactivation). The dose level and lamp type seem to affect the degree of reactivation, with low pressure (single wavelength) UV lamps appearing to be more susceptible to photoreactivation than medium pressure (multi-wavelength) lamps, according to studies published over the last five years in Water Science & Technology, Journal of Environmental Engineering & Science, and Applied & Environmental Technology. A much larger research effort into the area of photoreactivation is required and will most likely be forthcoming over the next few years.

A significant amount of research also has targeted the question of UV disinfection by-products (DBPs), specifically the most common water constituents such as chlorine, bromide, nitrate, ozone, natural organic matter (NOM) and iron. At normal UV disinfection doses, no significant DBPs have been shown to form.

Benefits for Reuse Market

The most common method of wastewater disinfection for reuse has long been chlorination. Despite chlorine’s impressive track record, concerns regarding DBPs and, more recently, disinfection performance with respect to pathogen inactivation, are driving the conversion from chlorine disinfection to other disinfection methods such as UV, which does not produce any DBPs in and of itself.

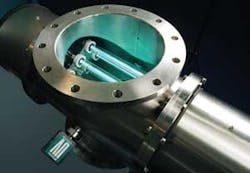

Closed vessel UV systems are easy to install within existing pipework, so there’s minimal disruption to plant operation. Day-to-day operation is simple and only minor maintenance is needed. Most often, the only regular requirement is changing the UV lamps and wiper rings once a year, a straightforward operation that can be carried out by onsite personnel.

UV systems for wastewater reuse are also validated to much higher doses than drinking water systems, according to protocols established by the National Water Research Institute (NWRI) in the USA. Drinking water type product validation, with the accompanying rigor, will emerge as the dominant method of assessing suitability for these critical applications. The ability to prevent photo repair will also emerge as key.

Wastewater Applications

Potential applications for wastewater reuse are extremely wide-ranging and include any instance where water is needed for non-potable use. The most popular and widespread use is for agricultural irrigation, with California and Florida leading the way in the USA and a number of Australian states also making significant progress. Other irrigation uses include landscape and recreational applications such as golf courses, parks and lawns.

Reclaimed wastewater is also used for groundwater recharge applications such as aquifer storage and recovery or preventing saltwater intrusion in coastal aquifers. Other uses include toilet and urinal flushing, firefighting, foundation stabilization in the construction industry and artificial snow generation. In all these applications, reuse wastewater relieves the burden on existing municipal potable supplies.

Three Case Studies

Arizona, USA – Two golf courses in Anthem, Arizona, are using UV-treated wastewater for irrigation. Founded less than 10 years ago, the planned community just north of Phoenix has a population of over 40,000. As part of its rapid expansion, it recently installed three closed chamber, medium pressure UV systems from Berson UV-techniek to disinfect its wastewater. This allows Anthem to not only meet increased demands in its water and wastewater treatment capacity, but also to exceed the output quality standards.

“The wastewater is treated by three bersonInLine systems handling a combined flow of 3 mgd”, explained Anthem’s wastewater foreman Jeff Marlow. “They work in conjunction with microfiltration and nitrification/denitrification. We chose the Berson UV systems because they are optimized to meet the upcoming Arizona Pollutant Discharge Elimination System (AZPDES) Permit Program”.

The two local golf courses currently use a combination of UV treated wastewater and fresh river water for irrigation, but with increases in population, it’s expected that the courses will soon be using wastewater exclusively.

An automatic cleaning mechanism keeps the lamp sleeves free of organic deposits for consistent UV dosing. Each chamber is also fitted with monitors to measure actual UV dose for recordkeeping. With the addition of an optional online transmittance monitor, real time transmittance values are used to automatically adjust dose pacing of the UV system.

Murcia, Spain – UV technology also is used to treat municipal effluent for irrigating crops in the arid Murcia region of Spain, which enjoys a microclimate allowing fruit and vegetables to be grown year round. Low rainfall means treated wastewater also is necessary for watering crops. The effluent supply is gravity-fed, so the disinfection system is very susceptible to pressure loss.

Medium pressure UV technology was the choice of treatment system, as the low number of UV lamps in each chamber offers less resistance to fluid flow, resulting in lower overall head loss. Medium pressure technology also results in energy and component savings for the system operators and is more reliable at permanently destroying microorganisms.

The installation – one of the first schemes of its kind in Europe – consists of three medium pressure UV treatment chambers installed in series, treating a combined effluent volume of over 130,000 gph (500m3/hour) and run normally 16 hours a day, although they can operate 24 hours a day if required.

New South Wales, Australia – Lastly, the Goulburn Mulwaree Council awarded a contract in October 2006 to Contra Shear Technology to supply a Berson medium pressure UV system to Ted Wilson & Sons for the council’s Sewerage Augmentation Irrigation facility at its Gorman Road Plant at Goulburn in New South Wales. The project utilizes five medium pressure UV systems. The design by TWS represented a substantial savings in civil works and power facilitated by Berson’s technology.

Other efforts using UV as part of a public works treatment regimen to recycle wastewater have been evaluated and proven successful in Bilbao, Spain, L’Aquila and West Bari, Italy, Parsippany, New Jersey, USA, and Tokyo, Japan’s Meguro River.

Conclusion

The UV industry has matured considerably over the last decade and is now more highly regulated and dominated by the world’s major water technology companies. Conventional UV technologies are field tested and now have considerable track records in a wide range of applications. Uncertainties surrounding regulations, royalties, technology and engineering have decreased and acceptance of UV is expected to grow rapidly over the next 20 years. UV system designs have been greatly aided by CFD, which will be used as a routine sizing tool for future designs.

The stage is now set for dramatic growth in the wastewater reuse market, especially with increasing populations putting even more pressure on already overstretched water resources in many regions of the world. Tighter limitations on pollution discharge will also play an important role in the development of this technology.

Author’s Note:

Sjors van Gaalen is the managing director of Berson UV-techniek, of Nuenen, The Netherlands. Berson is a unit of Halma p.l.c., a specialist in electronic, safety and environmental technologies with 40 subsidiaries and 3,000 employees worldwide. Contact: +31 40 290 7777, [email protected] or www.bersonuv.com