Technologies & Products

Photometers speed up monitoring tasks

Macherey-Nagel launched two new photometers for water and wastewater analysis - the Compact Photometer Nanocolor® 400D for routine water analysis; and the Scanning Spectrophotometer Nanocolor® Linus for analytical tasks. With in-built laser scanner, Nanocolor photometers identify bar-coded Nanocolor test tubes when inserted into the cuvette slot. Following the information coded on the test tubes' bar coded labels, the photometers carry out the selection of precalibrated methods, wavelength adjustment and the measurement automatically without any keystroke.

Together with Nanocolor® reagent sets, the photometers analyse COD, BOD, TOC, AOX, nitrate, total nitrogen, phosphate, various metals and other parameters.

Macherey-Nagel

Düren, Germany

Contactor removes CO2 and O2

The Liqui-Cell 6 x 28 Membrane Contactor is the only integrally potted membrane contactor manufactured with this large diameter, according to Celguard. Its integral potting allows the elastomeric o-ring seal to be eliminated. Used primarily to remove CO2 and O2, the contactor handles flow rates of 1 to 10m3/hr.

The membrane contactors make it possible to transfer gas to or from an aqueous stream without dispersion. They contain thousands of Celgard® microporous polypropylene hollow fibres, which are knit into an array and wound around a distribution tube. The aqueous stream will not penetrate the pores because the hollow fibre membrane is hydrophobic. The gas/liquid interface is immobilised at the pore by applying a higher pressure to the aqueous stream relative to the gas stream. Liqui-Cel Membrane Contactors provide a constant interfacial area for transfer over the entire operating range of flow rates. The surface area per unit volume is an order of magnitude higher than traditional technologies, which leads to dramatic reduction in contactor/system size for a given level of performance.

Celguard, Inc.

Charlotte, North Carolina, USA

CHS saves O&M costs at power station

Standard Alloys develops Custom Hydraulic Solutions (CMS) for companies that want to reduce or eliminate cavitation, increase capacity and reduce power consumption. The company reports that its latest CMS for a large power-generating station in the Northeast USA produced cost savings in operations and maintenance.

A 46-inch custom impeller design for pumps used in the circulating water system increased the capacity of the Worthington pump from 88,000 gpm at 96-ft Total Developed Head (TDH) to 94,000 gpm at 100-ft TDH. The CHS decreased the Net Positive Suction Head Required (NPSHR) from 22 ft to 17 ft at the 94,000 gpm flow, thereby reducing pump cavitation. In addition, amp loading on the 2,500-hp motor decreased from 329 to 319 with the increased capacity.

Standard Alloys

Port Arthur, Texas, USA

Monitor measures ORP potential

The 720 Series II pH and ORP monitor/controllers measure pH or oxidation-reduction potential/redox in reverse osmosis, process control, seawater desalination and waste treatment. The equipment features "isolated" circuitry, built-in electronic calibration, internal alarm set, 10-amp output relay, push-to-test button for set point checks, bright green and red LEDs to indicate above or below set point readings. An IP64/NEMA 3 splash and corrosion-proof rated enclosure in a compact size - 152 x 122 mm) make the 720 Series II models suitable for panel, bench or surface mounting.

Myron L Company

Carlsbad, California, USA

RO element design improves cleaning

The FilmTec SW30HR-320 High Rejection Seawater Reverse Osmosis (RO) Element purifies seawater sources such as open intakes, where there is high potential for membrane fouling. According to FilmTec, the element is rated at 99.6% salt rejection and delivers high quality potable water.

Dow incorporated features that improve membrane cleaning of scale, organic compounds and biofilm. These features include a thick feed spacer (34 mil) and a greater number of shorter membrane leaves to reduce the overall effect of fouling. Thicker feed spacers reduce pressure drop and cleaning frequency. Dow developed this element to replace the FilmTec SW30HR-8040 element.

The Dow Chemical Company

Minneapolis, Minnesota, USA

Biological process treats poultry wastewater

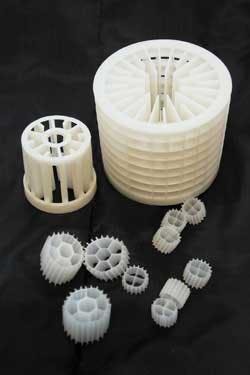

The Kaldnes Moving Bed Biofilm Reactor (MBBR) handles wastewater with high BOD concentration and large load variations produced in the poultry processing industry while lowering costs associated with the operation of the wastewater treatment plant. The process uses existing equipment located on-site for retrofitting with the MBBR process components.

The Kaldnes process package design consists of one or two MBBRs, depending on the treatment required and placed after the equalisation tank. The MBBR process consists of thousands of tiny, polyethylene biofilm elements to provide a home for a vast, highly active bacteria culture. These buoyant elements are kept in constant motion throughout the entire volume of the reactor, resulting in uniform, highly effective treatment. Effluent from the MBBR is either clarified or it flows directly into an existing biological treatment system on-site.

Kaldnes North America

Providence, Rhode Island, USA