Optimising Wastewater Treatment with Ion-selective Measurement Technology

Obtaining accurate measurements at wastewater treatment plants is fundamental in order to meet ever-increasing restrictions. Dr. Klaus Reithmayer and Robert Hengel detail an experiment carried out at the Strass wastewater plant in Austria, to test direct measurement ion-selective probes in a comparison against existing automatic analysers.

The central wastewater treatment plant in Strass has a capacity of 167,000 population equivalents (PE), servicing an area extending from the Archenpass to the Hintertux glacier. Due to tourism the load on the ARA sewers and wastewater treatment plant reaches its maximum in the peak holiday seasons, July/August and the Christmas holidays.

The activated sludge plant in Strass has an upstream, high-rate biological system. After intermediate sedimentation, the pre-cleaned wastewater passes through a two-lane, low-rate biological system where each lane has two tanks. The wastewater is denitrified in the first tank and nitrified in the second.

Depending on the amount of wastewater, the denitrification zone can also be aerated so it can be used as an additional nitrification area. This is controlled in the joint outlet of the two activated sludge lanes by the ammonium values determined online. Recirculation pumps are also controlled by the ammonium value. For further control, the oxygen measurements in the activated sludge are used for direct control of aerators.

Until recently, the treatment plant measured ammonium, nitrate and phosphate nutrient parameters following ultra-filtration by automatic analysers. This method not only required a lot of maintenance but also necessitated a huge ongoing consumables stream. The plant felt that although this measurement technology ran competently it was becoming increasingly outdated in comparison to emerging technologies. In order to assess the potential benefits of implementing more current technology, new direct measurement ion-selective probes were tested against the plant's existing automatic analysers. The comparison focused primarily on quality of measured data, reliability of measurement, system availability, maintenance, calibration costs and durability.

Implementation and comparison

The WTW VARiON probe from Xylem Analytics was installed in the combined outlet of the two activated sludge lanes. The additional probe was simply installed in the plant's existing IQ Sensor Net system, which consists of a number of oxygen/pH and turbidity sensors. This meant that the installation required no additional investment other than the probe itself.

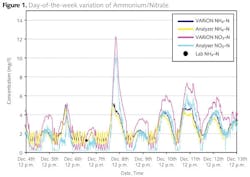

Measured data was stored in the system and, where possible, also transferred directly to the process control system. This enabled an accurate online comparison with the available analyzer values, indicating day-of-the-week variation of ammonium/nitrate (see Figure 1).

Over the selected time period from the beginning of December, the transition from intermittent operation to 'peak season' operation is clearly visible with a distinctive diurnal variation. The low temperatures hampering denitrification and nitrification made the control/regulation of the process a challenge. Throughout the trial, both the ammonium values and the nitrate values indicated by the probe were consistent with the values indicated by the automatic analyzer. Reference measurements performed in the laboratory (double photometric determinations and ion chromatographic measurements) match the online measurement curves (see Figure 2).

However, in December of that year, the automatic ammonium analyser was subject to failure and could not be relied upon to provide accurate data for this period. As a solution, the ammonium values of the ion-selective probe were used for control and regulation purposes from that time, indicating the superior reliability, durability and accuracy of this technology. Depending on the requirements for absolute accuracy, a regular check with laboratory reference values is useful in order to comply with quality standards related to process management and sensor technology. Overall, costs associated with the maintenance and calibration of the ion-selective probe technology were low.

The probes were routinely subjected to a maintenance check, however as a result of the integrated and automatic compressed-air cleaning function, no additional manual cleaning or maintenance was necessary. Occasionally measured values were validated using comparative measurements in the laboratory, with minimal deviations recorded and no additional calibration necessary. The ammonium and the nitrate electrode were recalibrated for the first time after approximately three months of use.

After a six month trial comparison, results compiled by the wastewater treatment plant at Strass indicate that the latest ion-selective probe technology provides data quality consistent with the automatic analyzer. The overall results of the comparison suggest that ion-selective probe technology offers a cost effective alternative for smaller wastewater treatment plants, while still providing a high level of reliability and data quality.

Author's note: Dr. Klaus Reithmayer is product manager and Robert Hengel is wastewater market leader at WTW, a Xylem brand. For more information email: [email protected] and [email protected].

More Water & WasteWater International Current Issue Articles

More Water & WasteWater International Archives Issue Articles