Dual-Membrane Technology Enables Water Reuse in Gaojing Power Plant

Constructed in the 1960s by Datang Corporation and located in Mengtougou, the Gaojing China Power Plant is one of the earliest to supply heat and electricity to Bejiing's local communities and industries. Water recycling systems for cooling tower blowdown have become more and more common in fossil fuel power plants because of the large volume (about 60% of all wastewater comes from power plants). Therefore, there was a high need to ensure positive reuse of cooling tower blow down for boiler feed water.

In 2003, the plant engineers selected Dow Ultrafiltration modules and Dow Filmtec brackish water reverse osmosis elements as a solution for reuse using the blow down from their cooling towers as boiler feed water. For proper pre-treatment and chemical dosing, Dow Ultrafiltration modules and FILMTEC membranes were also used to help eliminate problems in subsequent wastewater reuse systems.

Traditionally, the source of the cooling tower makeup at Gaojing was from surface water, but was changed to secondary effluent from the Gaobeidian Municipal Wastewater Treatment Plant in 2007. Due to this type of wastewater concentration, contaminants varied substantially between seasons and cooling tower makeup quality.

At this time, the engineers selected Dow Water & Process Solutions' dual-membrane technology to overcome a waste stream containing high hardness, alkalinity, silicon dioxide and sulfate, typical in cooling water blow down to help the power plant meet increasing environmental requirements from the government. The integrated technology, together with proper pre-treatment and chemical dosing, helped the plant to realise more than 70% reuse of the cooling tower blow down - even after five years of operation.

This dual-membrane solution consists of Dow Ultrafiltration SFP-2660 and Dow Filmtec BW30-365FR and BW30-400 reverse osmosis membranes.

Process Flow and Key Treatment Units

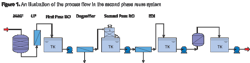

As can be seen in Figure 1, the blowdown water was first pumped into a multi-media filter to remove suspended solids and reduce the turbidity. Then the UF unit further decreased the turbidity and protected the subsequent RO unit from colloids, suspended solids, bacteria and large molecular weight organics.

Reducing agents, anti-scalant and acid were then dosed before the first pass RO system, in which most of the dissolved solids and SiO2 were removed.

The permeate water from the first pass RO was then degasified, and the pH was increased to 9.5 by NaOH dosing before entering the second pass RO. In the end, EDI was installed for final demineralization to meet the requirement of boiler make up. Dow's experience in membrane technology enabled them to offer innovative solutions to guide application development in this area. As in the case of Gaojing Power Plant, dual membrane technology together with proper pre-treatment and chemical dosing helped them to realise more than 70% reuse of the cooling tower blowdown.

More Water & WasteWater International Current Issue Articles

More Water & WasteWater International Archives Issue Articles