Slovakian Hybrid Tunneling Project an Open and Shut Case

By Peter Juhas & Alexandra Dobnigg

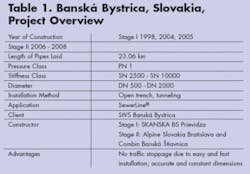

HOBAS SewerLine installation in Banská Bystrica requires trenchless and open-cut methods over 23 kilometers.

Reasons to establish a new sewage system in Banská Bystrica, Slovakia, were primarily to increase the capacity of the wastewater line leading to the city’s wastewater treatment plant (WWTP) and to extend and modernize the whole sewage system. This subsequently would allow further growth of Banská Bystrica and all surrounding areas.

The decision for construction was made in the 1980s. The project was divided into two phases: An interceptor A would be built along with the extension of the treatment plant and then the sewer network in Banská Bystrica and its surroundings would be reconstructed and extended.

A concrete interceptor was originally installed. Having reassessed its hydraulic qualities, however, the client reconsidered and opted for HOBAS® CC-GRP (centrifugally cast glass fibre reinforced plastic) pipe systems. After delivery of a HOBAS SewerLine® DN 2000 pipe, the works were stopped since the project was included in the European Pre-Accession Program ISPA. The project was technically filed by EU experts and redesigned to utilize HOBAS® CC-GRP HOBAS SewerLine DN 1800 and SN 5000 pipes. Decisive criteria were leak-tightness, durability, hydraulic and long-term static characteristics as well as numerous similar reference projects involving similar constructions to demonstrate the experience of HOBAS in the field.

The construction of the first phase of the DN 1800 interceptor was divided into two sections. The first section of 1.8 km was laid by open cut and the second 2.1-km long section was installed by tunneling.

Open cut was chosen for a section where the traffic wouldn’t be disrupted. The pipe bed and the zones around the pipes were filled with gravel sand and compacted. The section situated in areas of heavy traffic was constructed with the help of trenchless technology, namely tunnel boring. Steel and concrete casing pipes were used for tunneling. The gap between the CC-GRP pipe and the casing pipe was then filled with suitable material.

In addition to the pipes, HOBAS CC-GRP manholes were supplied as well to guarantee the leak-tightness of the complete sewer network and not just the pipeline itself.

The construction of sewage system realized directly in town was optimally timed since it was conducted without stopping traffic flow. HOBAS CC-GRP pipe systems proved to be highly advantageous during this phase, since their light weight and their push-to-fit couplings facilitated the installation considerably – even the larger diameters were easily aligned and jointed. Easy handling, simple jointing and dimensional accuracy confirmed that the client made the right choice.

null

Author’s Note:

Peter Juhas is managing director of HOBAS Slovakia and Alexandra Dobnigg is a marketing coordinator for Klagenfurt, Austria-based HOBAS Engineering GmbH, which is part of the HOBAS Group. With 35 HOBAS Group-owned production facilities and sales organizations in Europe and America as well as joint ventures and license partners, HOBAS manufactures and distributes CC-GRP pipe systems worldwide. Contact: +43-463-48 24 24-38, [email protected] or www.hobas.com