Backwards and Forwards, from Single-Source to Best-of-Breed

Retrofitting an MBR system can offer multiple benefits for various applications, whether those are for municipal, industrial or landfill leachate wastewater treatment.

null

Submerged membrane bioreactor (MBR) technology continues to experience rapid growth due to its two main advantages over conventional biological wastewater treatment systems: significantly improved effluent quality, and a substantially smaller footprint. Throughout the past decade, MBR systems have been installed in thousands of municipal and industrial wastewater treatment plants (WWTPs) of all sizes for a variety of challenging wastewater applications for plants like paper mills, breweries, food processors, chemical plants and textile manufacturers.

The history of membrane bioreactors follows a typical pattern of technological evolution. The idea of coupling an activated sludge bioreactor with an external membrane separation system dates back to the mid-1960s. The concept of submerging membranes in the aerated bioreactor was first conceived in the late 1980s and early 1990s when independent teams in Japan and North America experimented with different membrane designs, notably hollow fibers and flat sheet panels. A number of proprietary MBR systems became commercially available, and each vendor has refined its respective designs. As a result, the industry as a whole has benefited from the independent and competing innovations of the various MBR manufacturers.

Existing MBR users seek to benefit from these technological advances, especially as their first generation product reaches the end of its useful life. Most find that to implement the latest technology in their plant, the investment in changes to infrastructure, piping and utilities are miniscule when compared to the dramatic savings in lifecycle costs attainable with the newer designs.

Second Generation MBR

In recent years, MBR membranes have evolved to the point that they require less maintenance and have a longer useful life. An added benefit comes from more advanced designs that consume significantly less energy and enjoy lower operating costs.

The new PURON™ module from Koch Membrane Systems Inc. (KMS) is a second generation MBR membrane module employ-ing hollow fibers. Like several other second generation membranes, the high-strength fibers that comprise these modules also overcome fiber breakage problems typical of first generation systems utilizing non-braided fibers. Unlike the “double header” design of other hollow fiber MBR membrane that pot the hollow fibers at both ends, this module uses a single header with hollow fibers potted at the base, allowing the tips of the fibers to float freely at the top with a seaweed-like action. This design innovation eliminates build-up of hair and other fibrous debris by allowing the material to pass through the module rather than collecting at the top as is typical of dual header designs. Compared to double header designs, this design also places less mechanical stress on the fibers.

Another advantage of the single header design is the introduction of air scouring at the center of the fiber bundle. Low pressure compressed air creates coarse bubbles that shake the membranes and effectively scour the entire fiber length, enabling the air to remove accumulated debris from the membrane fibers within the bundle. The ability to supply compressed air in a cyclical pattern avoids sludging and reduces energy consumption.

Unlike most flat sheet membranes that don’t accommodate backflushing, the PURON membrane resists fouling and maintains flux by introducing a small portion of the filtrate back through the fiber pores from the inside-out at timed intervals. Its hollow fibers provide significantly higher membrane surface area and filtration capacity within the same module footprint compared to flat sheet membrane designs.

Retrofit Considerations

For these reasons, a growing number of WWTP operators have opted to replace their first generation MBR modules with PURON modules. When planning such a retrofit installation, several factors must be considered:

Performance of the MBR System – The most important consideration in retrofitting an existing MBR is biological system performance. In many cases, poor performance in the bioreactor will result in problems with membrane performance. In such situations, changes to the biological treatment system may be needed to improve the system, as simply changing the membrane modules may not be sufficient.

Physical Module Dimensions – New modules must have a flexible design to accommodate existing tank size and module layout. The frame of the new modules must have the necessary exterior dimensions (height, width, length). Membrane area must also closely match the system design to support the required operating flux.

For example, the new 1,500-m2 module from KMS is designed specifically for large-scale MBR retrofit applications. Features such as optimized permeate extraction manifold and air supply lines reduce piping connections during installation.

Module Operation – Each MBR manufacturer has optimized performance in different ways depending on the membrane module and membrane configuration. Careful consideration is required to evaluate existing equipment that supports backwashing, air scouring and chemical cleaning sequences. This equipment may need modification or an upgrade along with a membrane retrofit.

For example, some systems backwash the membranes with permeate while others don’t. The choice depends on robustness of the membrane when pressure is applied from the opposite direction. Typically, flat sheet membranes and some unsupported hollow fibers cannot be backwashed. Therefore, the necessary piping and pumping capacity for backwashing may not be in place.

Moreover, membrane manufacturers use different air flow rates and cycle times for air scouring on those systems able to cycle the delivery of air. Therefore, retrofit installations may require adjustments to the air scouring sequence (typically a programming issue), and changes to the size of blowers and position of automatic valves that move air.

Three Case Studies

• Municipal Wastewater – An example of a municipal MBR module retrofit is the WWTP that serves Thélus, a community near Calais in the north of France. Generale-des-Eaux, a Veolia Water company, was using a municipal MBR to treat wastewater from this community since 2000. Reliability and energy consumption of the existing double-header hollow fiber membrane modules, however, never met the operator’s expectations. Therefore, in June 2006, the plant owner chose to retrofit the system with second generation PURON membrane modules.

null

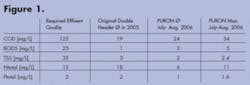

The retrofitted MBR plant now has a capacity of 90,000 gallons per day (gpd) – or 335 cubic meters per day (m3/day). Incoming wastewater passes through a 1-mm slot screen prior to entering the MBR. The blower for air scouring of the membrane modules was replaced by a unit half the size of its predecessor due to reduced air scour demands of the single header design that uses central aeration. The reduced air scour demand of the new membrane module reduced dissolved oxygen (DO) concentration in the recycle flow, thereby reducing air entering the denitrification zone, improving overall denitrification performance of the system. As a result, effluent values for total nitrogen have dropped considerably and effluent quality has improved significantly (see Figure 1).

• Landfill Leachate – Another example of a retrofit is at the Ecopark De Wierde landfill for household and industrial waste in the Netherlands. Leachate from the landfill had been treated by means of a membrane bioreactor since February 2003, but in 2004 the 126,000 gpd (477 m3/day) capacity of the system was insufficient and consideration was given to expanding the MBR to 222,000 gpd (833 m3/day) hydraulic capacity. In September 2005, two second generation PURON membrane modules were installed and operated in parallel with the existing MBR modules. This system was the first of its kind to employ submerged membrane modules from two different manufacturers. The stable performance of the new MBR modules was very encouraging, and after one year, the operator chose to retrofit the remaining two original double header modules. The retrofit was conducted in just one day.

• Trucking Company – Belgium transport company Dekker had been operating a WWTP with submerged MBR membrane technology for a few years. The existing system was a first generation membrane design with non-reinforced hollow fibers fixed at both ends. The original membrane experienced various problems including fiber breakage and low membrane permeability as the existing membrane wasn’t capable of a backwashing operation. After careful consideration, the existing membrane modules were replaced by single header design modules that utilize a reinforced membrane fiber which supports backwashing and contains a total membrane area of 2,500 ft2 (232 m2).

Conclusion

Second generation systems position the membrane bioreactor industry for even more rapid growth. They offer several advantages, including improved performance in terms of reduced fouling and lower energy consumption. They are also more robust than first generation systems and are usually designed with compatibility in mind to minimize retrofitting costs.

Based in Wilmington, Massachusetts, USA, Koch Membrane Systems Inc. is part of Koch Chemical Technology Group LLC. With over 15,000 membrane systems installed worldwide, it serves food processing, life sciences, and general manufacturing industries, as well as provides potable water and wastewater treatment technologies for communities of all sizes. Contact: +1-888-677-5624, [email protected] or www.kochmembrane.com