Pond on a Pond

Water harvesting system meets aesthetic, functional objectives

By Dustin Glist

When Lakehead University officials started the quest for a LEED™ (Leadership in Energy and Environmental Design) certified facility, they had no idea that the design engineers would take them into uncharted territory. The university’s new facility in Orillia, Ontario, will represent the first university in North America to get the LEED™ Platinum standard.

In addition to achieving this environmental standard for the Orillia campus, the designers had something else unique in mind: a large decorative water feature pond supplied by rainwater captured in an underground harvesting system. The concept may not seem unique — until you consider that the harvesting system sits directly below the pond and also supplies gray water for toilet flushing.

Construction of the CAD $45 million academic building began in the summer of 2009. The 80,000 square foot facility will accommodate 1,200 students and is the first of three buildings expected to open in September 2010. The decorative pond was built in front of the 250-bed residence and a food services building.

Figure 1: Stackable and modular units make up the subsurface stormwater harvesting and detention system.

Michael Buske, CET, along with engineer Tim Collingwood, project manager with CC Tatham & Associates, designed the unique system to capture stormwater from the adjacent road. The runoff flows into a catch basin, moves through a filtering system, flows to a chamber for storage, and from there is pumped to the aboveground water feature. The underground chamber was originally designed to be both a harvesting (gray water reuse) and a detention (exfiltration and release) system. The system also includes an outlet pipe to the city’s combined storm sewer system and a manhole for maintenance. In addition to supporting the water feature, some of the captured gray water is also used for toilet and urinal flushing to reduce fresh water use in the building.

According to Buske, during construction, it was determined that the system should be fully wrapped in the impermeable liner since it would be very difficult to interface the permeable top and impermeable bottom liners. This turned the underground portion into a full capture and reuse harvesting system. When the system reaches capacity, it utilizes an overflow pipe connected to the municipal stormwater system.

For the underground harvesting system, engineers selected Rainstore3 by Invisible Structures, Inc. (Golden, CO). Modular and stackable, the system is designed for underground storage of water for retention, detention and harvesting. The entire chamber at Lakehead University is comprised of 6,000 units stacked into two-meter-high cells and is capable of holding 564 cubic meters of water.

“This system was selected for the high storage volume in a smaller area as compared to a clear stone, French drain-type design,” said Collingwood. It was also attractive to the designer for its structural ability to support the load of the water feature pond directly on top of the system.

“We needed to calculate the compressive load of the water, the concrete and the granular aggregate above the Rainstore3 chamber to see the effect it would have on the system,” explained Kate Wright, engineer with Invisible Structures. It was determined that the filled ponds and components would exert a point load of 505 psf on the chamber, well within the limits of the system, which can withstand in excess of H-20 bridge loading standards.

Figure 2: Nearly completed, the lined subsurface harvesting/retention system is ready for the granular aggregate and the concrete decorative pond to go on top.

The decorative surface ponds, which were designed for the enjoyment of students, faculty and staff of the Orillia Campus, are comprised of 30 cm thick reinforced poured concrete with waterproofing. The pond is about one meter deep, 4.4 meters wide, and runs the full length of the underground harvesting system. The ponds have a wood decking plaza surrounding, and partially traversing, the water feature. Below the decking is reinforced concrete with strategically placed drainage holes. The holes lead into a granular aggregate designed to drain and convey the water towards the harvesting system.

The captured stormwater in the subsurface harvesting chamber is also recycled as gray water for toilet and urinal flushing inside the building. The water is pumped from the chamber to a sand filter package and then pumped to the gray water system inside the building. Engineer Greg Gebert, Project Manager with Crossey Engineering, designed the mechanical systems for the Orillia Campus building project.

The gray water system is completely separate from the fresh water/potable system provided by the city. The wastewater from the toilets will flow to the municipal sewage treatment.

The reuse of stormwater and the reduction in the use of fresh (potable) water will contribute to the LEED™ Platinum rating on the project.

Although LEED™ Platinum Certification for the project won’t come until after completion, the stormwater containment and reuse portion can contribute in the following categories:

Reduced water use — The surface pond is filled with harvested stormwater instead of potable municipal water, reducing the water use, and the toilets are flushed with filtered gray water instead of potable water.

Innovative wastewater technologies — The excess stormwater not needed for the pond is returned to the groundwater supply by exfiltration in the detention portion of the system.

Stormwater design — By capturing the stormwater onsite for harvesting and infiltration, runoff volume and rate are reduced.

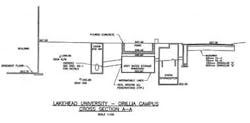

Figure 3: Cross-section detail of the stormwater capture and reuse system. Provided by CC Tatham and Associates.

Recycled content — Rainstore3 is manufactured from 100% post-consumer recycled High Impact Polypropylene (HIPP) plastic.

The water feature ponds and toilet flushing systems were in the first phase of the stormwater treatment plan on the new site. The stormwater management plan includes three infiltration bioswale trenches centered in what will be the newly constructed parking lot. The parking lot will sheet flow all of the stormwater into the bioswales, which will be comprised of native plantings, granular aggregate, and underground detention chambers. The chambers will slowly release the captured stormwater back to the groundwater supply.

“We’ve had Rainstore3 serve all these individual stormwater functions before —harvesting for ponds, reuse for toilet flushing, detention systems, infiltration trench and bioswales,” said Wright. “But this is the first time they will be combined on one site. And, this is the first time we’ve had a pond on top of our system. We are very pleased to be a part of this site’s stormwater solution.”

About the Author

Dustin Glist is Media and Information Director with Invisible Structures, Inc. He has been in the geosynthetic and stormwater management industry for 10 years, specializing in porous pavement, stormwater detention, erosion control and drainage.