Maintaining Pipeline Infrastructure with the Right Video Equipment

By Richard Lindner

It’s no secret that any number of municipal water and wastewater pipeline challenges related to age, ground shifts, microbe-induced corrosion, tree roots and calcification can lead to costly and damaging sewer overflows, back-ups and environmental contamination.

Increasingly, engineers, managers, consultants and operations personnel are avoiding emergencies by using a variety of new technologies and methods that not only solve problems, but also help to identify them before they occur. This includes many new pipeline inspection innovations, which now allow maintenance professionals to capture and then analyze crisp video imagery from pipe of any condition, size, material and layout.

Among these innovations are new-generation push cameras and inspection crawlers, as well as zoom survey tools and sidewall scanning technologies. Each technology offers a combination of benefits that is sure to address unique municipal needs, as well as budgetary and manpower constraints. The trick is properly understanding each technology and then making an informed investment based on on-site demonstrations and in-depth field tests.

The Traveling Camera

Over the years, new delivery mechanisms have emerged to carry cameras deeper into pipelines, while capturing increasingly better images. At the lower end of the market are push cameras, which televise pipelines using a self-leveling camera head and shadowless LED illumination, both mounted to the end of a semi-rigid push rod.

Push cameras are typically good for televising up to 200’ of pipe, and are optimized for (and often the only suitable alternative for) pipes under 4” in diameter. In recent years, push cameras have evolved to incorporate text writers, which allow an operator to make onscreen annotations, as well as digital storage media such as hard drive disks. Higher-end push cameras offer the option of panning and tilting the camera, a feature that proves useful when a pipe dead-ends into a tank, vessel or mainline.

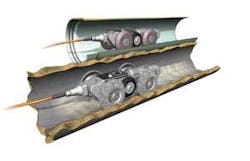

On the more sophisticated end is the video inspection crawler, a remotely-operated vehicle designed to carry a robotically articulated camera hundreds — even thousands — of feet into pipelines to identify corrosion, deposits, foreign matter, cracks, deformation, offsets and erosion.

However, even with the most advanced crawlers, decisions need to be made concerning the right tool for the job. For instance, a large mainline crawler won’t fit into a 4” line, nor would a 4”-capable crawler be suitable for a 60” trunk line with high flow. Special applications require special crawlers. Fortunately, most inspection work falls closer to the center of the bell curve — 8” to 24” lines — and most crawlers sold today target these applications.

But, questions still often arise as to size when choosing the appropriate crawler. As a result, many engineers and operations personnel in recent years have chosen more compact designs that have the flexibility to tackle larger applications. Many crawlers are now fully modular, and can be easily reconfigured to various line sizes with interchangeable wheels, lamps, cameras and camera elevators.

Another benefit provided by compact crawlers — especially those with a short wheelbase and six-wheel drive — is their ability to maneuver around protruding pipe taps, over thick patches of sediment, up offsets and through curved inverts.

Furthermore, while bulk is often associated with sturdiness, size and weight can also work against a crawler. In contrast to their larger counterparts, compact crawlers tend to pull with less force on their lightweight cables, and steerable crawlers require no periodic yank into alignment. Reducing these sources of cable strain reduces the frequency of cable retermination, the most common service procedure. Moreover, when service needs do arise, smaller crawler systems are cheaper to ship, maintain and repair.

null

Pipeline Zooming

Increasingly, public works professionals are turning to zooming, a pipeline inspection technique that delivers quick, comprehensive information about pipe conditions using inexpensive equipment and few personnel. The goal of zooming is to rapidly classify infrastructure as either satisfactory or in need of maintenance, repair/replacement, or additional CCTV inspection. These classifications allow a supervisor to prioritize maintenance activities confidently, committing precious maintenance resources — inspection crawlers, cleaning trucks, cutters/rodders, GPS surveyors, and grouting and relining crews — exactly where they’re needed most.

Inspection crawlers can’t be matched for their detailed, 360-degree inspection of pipe, but they move slowly, require substantial investment, and demand considerable manpower and overhead. By contrast, zooming allows a single operator to make a rapid visual assessment of pipe using an inexpensive, portable zoom inspection camera.

The simplicity of zooming is its power. A typical zoom inspection system consists of a camera, lamps, a positioning pole and a video display. Grasping the pole, an operator orients the camera to look down a section of pipe. Starting with a wide-angle view, the operator slowly increases zoom so the camera’s view advances down the pipe. In this manner, an operator inspects the entire length of the pipe for anomalies, and then classifies its condition accordingly. Zoom inspection cameras are also ideal for inspecting tanks and vessels with limited access, helping avoid the hazards of confined space entry.

Another benefit is also provided to cleaning crews, which often work more efficiently with the advantage of zoom inspection. With a quick glance down a line before cleaning, and then again afterward, an operator can instantly judge the effectiveness of cleaning or even monitor the efficacy of a specific cutter or nozzle in real time.

Manhole inspection is an integral part of infrastructure assessment, and some zoom cameras can be adapted for wide-angle viewing. A wide field of view allows a camera to see larger regions of a manhole wall or other up-close target. It also allows an operator to capture the entire circumference of a manhole wall from a downward-looking vantage point. Commonly, use of a wide-angle lens requires a lamp diffuser for even illumination.

Sidewall Scanning

Digital Visual Sidewall Scanning (DVSS) relies on the proven inspection crawler platform to gather visual data from within a pipe. However, unlike traditional video inspection, DVSS implements digital image processing to deliver rich information in a format that is easy to analyze.

DVSS relies on software to manipulate video frames into a flat digital scan. This scan resembles a long mural or scroll, and it bears an image whose length corresponds to the length of the pipe, and whose height represents the pipe’s full circumference, from 0 to 360 degrees. These scans capture a level of detail greater than conventional video, while presenting it in a format that is easier to review and analyze.

In addition, rather than sitting through hours of inspection video, an analyst can review an entire length of pipe at a time, quickly pinpointing problem areas and making annotations and measurements directly on the scan itself. This review is further aided by special client software that presents a thumbnail version of the entire scan (resembling a film strip), allowing quick navigation to specific regions of the scan. Drawing and annotation tools also allow analysts to mark-up the scan, while identifying pipe features and highlighting regions of concern.

Conclusion

Ultimately, there are many innovative alternatives for improving municipal pipe inspection capabilities. Fortunately, the decision doesn’t have to be entirely academic.

Engineers, maintenance personnel and other professionals should explore the options firsthand by requesting field demonstrations on their most challenging pipelines. This will allow them to throw all the curve balls they want — partial collapses, protruding taps, curved inverts, offsets, debris, roots, grease, flow — only to let the best technologies for the job reveal themselves. In this way, the true winners in the end will be the township and its residents. uwm

About the Author:

Richard Lindner, president of Envirosight, LLC, has 15 years of experience in the video inspection industry. Envirosight manufactures video pipeline inspection equipment for municipalities and contractors engaged in the maintenance and rehabilitation of underground infrastructure.