Louisiana Lift Station Repair Stands the Test of Time

By David Snider

Louisiana is known for its Creole culture, Cajun cuisine, music and fun-loving atmosphere, but it's also known for the character of its people, their willpower and ingenuity, especially in battling recent natural and manmade disasters. It's the same resourcefulness that individuals and entities in the wastewater industry use to solve major infrastructure challenges.

Wastewater infrastructure in the Gulf Coast region faces several unique challenges as the hot, humid climate and limited elevation create a breeding ground for corrosion. This corrosive environment causes problems within wastewater collection systems and treatment facilities that have to be addressed, either with repair or replacement, and the Jefferson Parish, LA, Lift Station was no exception.

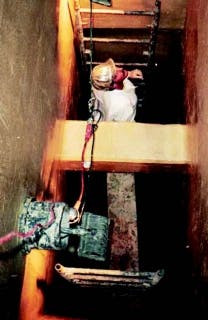

In 1988, the sewage pump station was in poor physical condition. The first issue was the process of biogenic corrosion (sometimes referred to as microbiologically induced corrosion), which erodes and destroys wastewater infrastructure. The second was the amount of inflow and infiltration (I&I) through cracks and failed seams and joints in the system.

In addition to the hydrogen sulfide gas, which contributes to the biogenic corrosion process, this particular lift station encountered a significant amount of turbulent flow and the resulting abrasion. The concrete was in extremely poor condition with exposed reinforcement bars easily visible. The engineering firm Meyer Engineering of Metairie, LA, faced the decision of either repairing or replacing the station. Several factors were taken into account, including the life expectancy of the station after repair or replacement and the costs involved.

Repair, Restoration and Protection

Meyer Engineering chose to repair the Jefferson Parish Lift Station by using an epoxy lining system to restore and protect it from further chemical attack. The system required a multi-stage process to achieve long-term success.

A detailed specification was prepared, which included language to guarantee that a single manufacturer provided all materials. This ensured compatibility of the materials. The installing contractor did an excellent job at properly preparing the structure prior to applying repair materials. This process entailed the removal of all loose, weak and chemically attacked concrete typically accomplished with the use of water blasting equipment. The entire structure was then abrasive blasted to profile the concrete and the exposed aggregate.

Prior to applying the lining, or corrosion barrier, more than one inch of concrete repair material was applied to the prepared substrate. A fast-setting, cement-based underlayment was used. It was imperative that this material be compatible with the corrosion barrier. Proper bonding of the topcoat to the underlayment helps restore the structural integrity of the system and also provides the maximum chemical resistance.

Another important part of compatibility is avoiding the potential of outgassing. Outgassing is when water vapor creates pressure under the coating, forms a blister and then bursts leaving a pinhole in the coating. This small failure in the lining can create an opening for sulfuric acid secreted by Thiobaccilus bacteria to reach and erode the concrete. Selecting products that refrain from outgassing was important for this project because the warm Louisiana temperatures tend to drive the moisture out of the underlayment, which would have elevated the water vapor pressure and likely caused blisters in the coating.

Corrosion Barrier

According to a 2010 independent survey, 80 percent of the participants agreed that chemical resistance is the top attribute in protective linings relative to the corrosion protection of infrastructure. Participants also recognized low permeance as the most important factor in the chemical resistance of a protective lining.

These characteristics were especially important for the Jefferson Parish Lift Station as it contained high levels of sulfuric acid.

Sauereisen's corrosion clad polymer liner, SewerGard™ No. 210, was selected for the Jefferson Parish project because it was one of the few epoxy mortars that satisfied the criteria of several independent tests, including the widely cited City and County of Los Angeles Redner Report. The trowel-applied polymer lining exhibits high chemical resistance and low permeability, along with high abrasion resistance and moisture tolerance.

Holiday Detection

As a quality assurance measure, the epoxy lining underwent High Voltage Spark Testing, which reveals any type of breach or pinhole in the lining not visible to the naked eye. If any such breaches went unrepaired, they would have allowed a pathway for acid to undercut the lining, leading to a premature failure.

The contractor, Python Corp. of Slidell, LA, marked all areas in need of touch-up as identified with the holiday detector, made the necessary repairs and then re-tested the repairs. This process ensured a pinhole-free lining.

As practiced in this project, part of the success behind the protective lining system was the detailed practices and procedures outlined by the manufacturer for installing the products. Manufacturers with a long history in an industry have developed procedures for all aspects of an installation, including steps such as surface preparation techniques, in-field quality control measures, etc.

The successful restoration of the lift station was, in no small part, due to Meyer Engineering's strategic attention to detail. The engineers were conscious of every element that would impact the longevity of the lift station. Selection of the correct products and application methodologies proved to be the foundation of an effective rehabilitation and corrosion protection project.

The lift station has received periodic inspections since the lining project was completed. In 2008, 20 years after the application, testing demonstrated the lining was still firmly bonded and protecting the concrete from chemical and physical attack.

Conclusion

There are instances where concrete in wastewater systems may be beyond repair, where replacement is the only option. In many cases, however, by specifying the proper materials, using the manufacturer's recommended application methods and employing quality assurance measures along the way, rehabilitation is not only feasible, but also quite practical.

In the case of the restoration of the Jefferson Parish Lift Station, the community saved considerable money in the short term, avoiding the additional expense and inconvenience required for full replacement. In addition, the epoxy lining continues to protect this valuable infrastructure asset from corrosion more than 20 years later. WW

About the author: David Snider is Western Regional Manager for Sauereisen Inc. of Pittsburgh, PA. He has 30-years of experience in the field of corrosion resistant materials of construction. In addition to sales, Snider has held positions in R&D, Quality Control and Technical Service. Sauereisen is a 111-year-old manufacturer of polymer systems used in a variety of applications.

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles