Big Success for PURON Modules Down Under

The papers in Australia are full of the plight of farmers due to extreme water shortage leaving water unavailable for irrigation. Membrane bioreactor (MBR) modules from Koch Membrane Systems are set to offer relief in the Bega Valley in New South Wales.

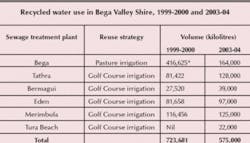

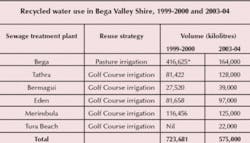

Membrane bioreactor modules from Koch Membrane Systems (KMS) have been specified for four MBR plants set to make a big impression in the Bega Valley of Australia, where drought conditions have persisted since 2002 requiring introduction of water conservation measures in urban areas along with increasing use of recycled water.

Bega Valley is located south of Canberra on the southeastern coastline of New South Wales in Australia and includes the villages of Cobargo, Wolumla, Kalaru and Candelo. The capacity of the valley’s wastewater treatment systems was being stretched by urban growth and seasonal population increases during summer holiday periods. Some unsewered villages in the valley were at risk for environmental and public health issues caused by discharge from existing septic tanks.

New pressurized sewage collection systems coupled with MBR treatment plants are being installed by Australian contractor Tenix Alliance to increase capacity and meet Australian Environmental Protection Agency standards.

In 2003, Tenix working with the Bega Valley Shire Council through TESIB (a Tenix Alliance business) formed the Bega Valley Sewerage Program (BVSP) to coordinate a A$60 million project - of which the New South Wales state government committed A$24 million in 2002 - to upgrade the wastewater treatment systems in five villages and add treatment for the unsewered communities.

“Pressure sewerage systems are being installed in each of the five villages”, BVSP Program Manager Warwick Stone told Local Government FOCUS, Australia’s national local government online newspaper in October 2006. “In four of the villages, state-of-the-art MBR technology is being employed to ensure the highest treatment quality available. This then will enable the beneficial reuse of reclaimed water on community land.”

MBR plants featuring PURON® membrane modules are being installed in the four villages along the valley. A proprietary feature of the module from KMS is the air nozzle, which discharges air from the center of each fibre bundle at the base. The combination of the rising air bubbles, the resulting hydraulic cross flow and the seaweed-like movement of the membrane fibres comprise an energy efficient process that ensures that sludge, hair and other fibrous components are dislodged from the membranes and moved safely out of the system.

Each plant has an operating capacity of 360m3/d (95,100 gpd), a footprint of approximately 20 x 15 m (66 ft x 49 ft) and will be equipped with two submerged MBR modules, each module providing a membrane area of 235 m2 (2.530 ft2).

The eight modules were shipped to Australia in August 2005. Commissioning of the individual plants has commenced with the MBR system in Cobargo now fitted with the KMS membrane systems and in operation. Upgrades at the Tathra and Tura Beach plants also are complete. And the entire program is set to be completed this year.

When all four systems are operational, the reclaimed water from the MBR plants will be used for irrigation on public facilities. Some of those that will benefit include the Cobargo Showground, Wolumla Recreation Reserve, Candelo Showground and the Sapphire Coast Turf Club. Tenix will operate and maintain the facilities for the duration of the contract, which lasts until 2017.

Authors Note:

Dirk Schlemper is European marketing manager for Koch Membrane Systems GmbH, an Aachen, Germany-based unit of Koch Membrane Systems Inc., which - with headquarters in Wilmington, Massachusetts, USA - has been a global leader in separation and filtration products for over 30 years. Contact: +49 241 413 260, [email protected] or www.kochmembrane.com