Grease degrades in low-flow lift stations

By Michael Harig

Fat, oil and grease (FOG) blockages in sewer system networks cause serious problems worldwide. For example, grease blockages in lift stations have reduced station capacity by up to 75 percent. Operating personnel face the challenge of maintaining existing wastewater infrastructure to keep customer complaints, sanitary sewer overflows, time and money spent on sewer blockages, and other reactive maintenance activities to a minimum.

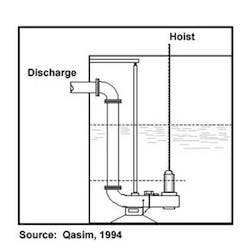

FOG from residential and commercial kitchens is transported in the collection system. As wastewater cools, FOG congeals on lift-station walls and pump hardware causing malfunctions. Grease that does not congeal on lift station surfaces can become a problem leading to sewer line maintenance or excess grease loading on the wastewater treatment plant downstream. Currently, when lift station flow is restricted or blocked due to grease accumulations, a high-pressure water jet truck or vacuum truck removes the grease. This approach creates other problems. Traffic is often disrupted and the grease is either collected for landfill disposal or forced downstream where it may redeposit , or increase treatment demand at the plant. Jetting and vacuuming are labour-intensive and expensive.

Bioaugmentation, the addition of live microbes, can reduce this cost but the process has typically been least effective in low-flow lift stations (< 200 m3/day). Novozymes Biologicals of Salem, Virginia, USA, conducted a field study to determine the effect of BI-CHEM® 2000GL modified with a recently commercialised bacterium, BioStrademark 3112, on FOG accumulation in low-flow lift stations.

Fats, oils and greases (FOG), whether of plant or animal origin, are composed of triglyceride molecules. These large, water-insoluble molecules are made up of a glycerol head group, connected via ester linkages to three fatty acid molecules; palmitic, stearic, and oleic acids, for example.

BI-CHEM 2000GL is specifically designed to degrade grease. The addition of BioS 3112, a newly discovered, patent-pending spore-forming bacterium, which degrades long-chain fatty acids that make up 90 percent of most grease deposits, enhances product effectiveness. This is significant since spore-forming strains are inherently more stable in commercial preparations. BioS 3112 exhibits degradation rates that are equal or better than vegetative (Gram-negative) strains previously isolated specifically, and believed required, for this capacity. Synergistic blending of the BioS 3112 with vegetative strains further increases degradation rates.

In the lift station environment, FOG degradation can only occur when a sufficient number of the microbes capable of degrading FOG are present. The bacteria that are present reduce grease and other organic compounds retained in the lift stations to soluble compounds and gases. The specialised strains in DC 2000GL, when added, greatly accelerated the breakdown of grease.

For the lift station used in this study, historic maintenance included weekly bioaugmentation using soluble one-pound packages of a commercial bacterial product followed by a monthly vacuum truck clean out. Maintenance procedures also included periodic washing using a high-pressure hose that loosened the grease mat from the walls of the lift station. According to the maintenance personnel, the historic bioaugmentation program softened the grease over time limiting hardware problems.

BioS™ treatment

The treatment program carried out by Novozymes Biologicals personnel included a weekly addition of two pounds of DC 2000GL with BioS 3112 in Sol-u-Paks. Monthly vacuum clean-out was discontinued. No other treatment was required or implemented during the study.

Field results demonstrated that DC 2000GL with BioS 3112 reduced grease deposits from 80% coverage of the lift station area down to 10% over three months. This approach reduced cleanout costs by 75% and operations and maintenance costs by 33%.

Author's note,

Michael Harig, P.E., is a member of the technical services team in the research and development department at Novozymes Biologicals, Inc, based in Salem, Virginia, USA. Visit the website: www.bi-chem.com for more information.