Round-up: Odor Control

A new bioscrubber tower system for odor control at the Anastasia Island Wastewater Treatment Plant (WWTP) in St. Augustine, Florida has successfully been started up.

The system will remove hydrogen sulfide (H2S) from air at the plant's headworks and the vertical Envirogen bioscrubber tower can handle high concentrations of H2S with a small physical footprint.

The Anastasia Island installation, located on a small island on the east coast of Florida, consists of two bio-trickling filter towers followed by a carbon adsorption unit for polishing. It is designed for 99% removal of H2S at airflow rates up to 4,600 cubic feet per minute (CFM) and will be handling relatively high inlet concentrations of H2S (500 – 1,000 ppm). In addition, the unit is built to withstand the hurricane-force wind conditions (up to 120 mph) that can occur in that region.

Larry Miller, chief engineer, Capital Projects for St. Johns County Utilities and project manager for the Anastasia Island plant expansion, said: "Initially, a chemical scrubber was specified for this project, until we determined that such a system would be cost prohibitive to operate given the high concentrations of H2S at the site. This bioscrubber tower gives us stable, low-maintenance performance in a tight footprint."

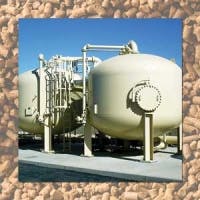

Envirogen's bioscrubber tower is a vertically oriented bio-trickling filter in which contaminated air is passed through a bed of inorganic media along with a recirculating water flow.

Naturally occurring microorganisms present on the media surface consume reduced sulfur compounds (including H2S), volatile organic compounds (VOC) and other odor-causing compounds, while the recirculation water allows for optimal control of pH, nutrient levels and biofilm thickness.

The system is self-regulating, requiring little or no operator attention and minimal energy to operate. The tower configuration is ideal for high contaminant concentrations, VOCs and where space is at a premium.

The systems can easily be expanded within the existing small footprint by adding vertical segments. Unlike chemical scrubbers, Envirogen's biofilters eliminate the need for expensive and potentially hazardous chemical storage and handling.

Low chemical and energy consumption and trouble-free operation allow these bioscrubber towers to deliver the lowest cost over the life of the installation.

Envirogen said Hydrogen sulfide is an odor-causing gas that occurs in almost every wastewater collection and treatment system in the United States, and poses both health threats and corrosive damage to treatment systems that can decrease use life and increase costs.

David Enegess, vice president of Envirogen Products and Envirogen's East Region, said: "From our early developmental work over a decade ago to a demonstration at a 1 billion gallon per day plant, we've been working to optimise biologically based odor control technology with good success."

Enegess added: "The result is an extremely efficient, low-cost system that reliably handles H2S and other odor-causing compounds with less energy, virtually no chemicals and with a smaller amount of land required than competing systems."

www.envirogen.com

Kruger, a Veolia Water Solutions & Technologies company, has introduced the new OdoWatch 3.0 system. This is an enhancement to the OdoWatch® real-time odor monitoring system which helps wastewater treatment plants stay on top of nuisance odors, preventing odors before they become a problem to the surrounding areas. Benefits of the new system include: new AERMOD modeling follows the odor plume over terrain, allowing plants to track odors more efficiently; The odor plume shows the separate odor contribution from each monitored source, making diagnosis and quick action on odor problems easier than before. An independent sensor option detects continuous H2S levels down to 2 ppb.

www.krugerusa.com

Biorem is a clean technology company that designs, supplies and distributes a line of high-efficiency biological-based air emissions control systems. These systems are used to eliminate odors, volatile organic compounds, hazardous air pollutants, and for the sweetening of biogas renewable energy. Its products are designed to meet the specific needs of the wastewater treatment process. The company offers a wide selection of products that can be custom tailored to meet application specific requirements.

www.biorem.biz

Parkson has introduced OHxyPhogg™, an odor removal technology with a patented air-atomizing 3-fluid nozzle. The system combines ozone, water and air, creating 5-micron sized oxidant enriched water particles that disperse and fill partially or fully enclosed spaces such as lift stations, wet wells, holding tanks and headworks. The oxidant fog reacts with H2S and other reduced sulfur compounds, removing the unpleasant odors. The technology also breaks down Fats, Oils, and Greases, virtually eliminating not only the buildup but also the pumping and discharging of FOGs. The system is customisable to meet varying installation requirements and can be installed indoors or outdoors. Five different unit sizes are available and multiple nozzles can be introduced based on the application requirements, odor levels and chamber size.

www.parkson.com

The ZABOCS™ process, available from Siemens, is a non-hazardous biological treatment system that combines gas adsorption with biological oxidation to capture and then eliminate organic and inorganic odors. This two-stage process combines biofiltration with an integral activated carbon media polishing stage. The system provides immediate odor control with zero acclimation period. It is available in nine models that range in capacity from 350 to 5,000 cfm. Manufactured from glass-reinforced plastic, the skid-mounted system is factory-assembled, charged with media and ready for site installation. Designed for unattended, automatic operation, the systems are ideal for remote wells, pumping stations and sewage collection systems.

www.siemens.com/water

More Water & WasteWater International Current Issue Articles

More Water & WasteWater International Archives Issue Articles