Sydney Water filtration plant upgrades actuators

Valve operation at an Australian Water Filtration Plant (WFP) at Nepean, 75km south of Sydney, will be supported by 60 of SIPOS Aktorik's variable speed, electric actuators. Located close to two dams, the Nepean WFP, owned by Sydney Water, incorporates a cluster of five filtration plants. Raw water is drawn from the Nepean dam and treated water is supplied to the townships of Bargo, Couridjah, Buxton, Thirlmere, Tahmoor, Picton and adjacent regions.

An upgrade of the scheme's 12 PLCs and SCADA system, comprising a primary and secondary server, is being implemented to enhance the speed of screen updates and reliability of the communication network. www.sipos.de

Membrane filtration elements to complement ion exchange resins

Chemicals company Lanxess has started production of its membrane filtration elements for reverse osmosis purposes at a new facility in Germany.

The first RO membrane elements will be available on the market in the beginning of 2012 and will be marketed under the brand name Lewabrane, to be sold alongside its ion exchange product range, Lewatit.

After final assembly, the RO elements have standard dimensions including a length of 40 inches and 8 inches in diameter. The active membrane surface of such an element amounts to approx. 400 square feet (approx. 37 square meters). The RO membrane element will provide rejection values of up to 99.7 percent with high water flux but this will vary according to feed water source and pretreatment design of the system.

The Lewabrane element family will consist of both 8 inch and 4 inch diameter membrane elements. Lanxess said the membranes operate according to the so-called cross-flow principle (tangential flow filtration, TFF), i.e. the majority of the feed water is not pressed right into the membrane (dead-end filtration) but travels tangentially across the surface of the filter membrane. This operation mode, the firm said, minimizes fouling and thus leads to an increased operation time of the membrane before cleaning or maintenance is required.

New hollow fiber ultrafiltration system

Koch Membrane Systems (KMS) has launched its new hollow-fiber ultrafiltration membrane system, the TARGA II HF system, which it said offers a high-quality water solution for a variety of ultrafiltration applications, from drinking water to seawater pre-treatment, industrial water treatment, and tertiary wastewater treatment.

The membrane element features a robust PES membrane which, combined with optimised cartridge and rack design, results in one of the smallest footprint products on the market. The fibers are said to be suited to meet drinking water requirements and provide 4-log virus removal.

KMS said intelligent process controls can handle variations in water quality and flow with minimal operator intervention, reduced chemical use, and less energy.www.kochmembrane.com

Ultra High Flow Rate Ceramic Membrane

Ireland-based Aqua Nu Filtration Systems has launched its patented Ultra High Unassisted Flow Rate Ceramic Membrane that it said achieves flow rates, for domestic and industry usage of up to 1.2 litres per minute over 11 sq centimetres at 100 millibar. The company said this rate is "up to 700 times faster than the closest rival in the ceramics market". The Aqua-Nu ceramic membrane has been scientifically tested and independently certified to remove Cryptosporidium 99.9999%, Giardia 99.9999%, E.coli 99.99%, Legionella 99.99%, and many more harmful microbes. www.aqua-nu.com/Technology.html

Industry book review: UF/MF membrane water treatment

Many books have been published in recent years on ultrafiltration and microfiltration in the water industry. However, UF/MF Membrane Water Treatment: Principles and Design by Dr Graeme K Pearce of Membrane Consultancy Associates is one of the few examples written by a single author, making it comprehensive and informative while being cohesive and non-repetitious. The structure is logical and consistent, and takes the reader through the stages needed for a thorough understanding of the subject: a true "ground-up" approach to the subject. The book uses many diagrams and illustrations to help explain the concepts, and has been written for an international audience with both SI and U.S. units. Each chapter has an extensive bibliography to reference ideas and give sources for further reading.

The book starts by setting the scene in the marketplace with a detailed discussion of drivers and trends, followed by the fundamentals and commercial products. Suppliers are further discussed in an Appendix, which allows a comparison between the products of all of the companies operating internationally. This again is quite rare in reference texts and, while not all the products will stand the test of time, all the established ones are listed.

Principles of system design are then tackled showing the common thread between the various suppliers. Applications are reviewed in detail, discussing contaminants in water and wastewater treatment often overlooked in other books. Case studies illustrate some of the key issues in the final chapter. Probably of more interest to users and operators is an intriguing chapter on problems and solutions, and how to operate your plant. A lot is known of these issues, particularly among the suppliers themselves, but they are often shy of airing any dirty linen in public. Once again, there are very few examples of where anyone has attempted to comprehensively bring this information together. All in all, a refreshing addition to this subject area.

- Independent review by Simon Judd, professor of Membrane Technology, Cranfield University, UK. For more information and to purchase a copy of the book, visit www.membraneconsultancy.com or email: [email protected].

Flexible ultrafiltration module for different setups

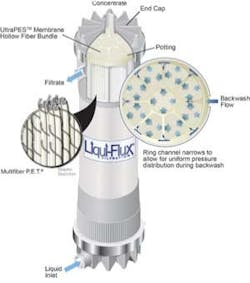

Membrana GmbH has introduced the Liqui-Flux® W10 Ultrafiltration Module that utilizes the proven UltraPESTM polyethersulfone membrane for inside-out operation. With 75 m2 of membrane area, the modules features the company's Variable Connect Concept - VCCTM. According to the manufacturer this development allows system integrators to select from a variety of connection options to accommodate different water qualities. Configurations include: the Standard Setup which features a radial feed inlet port and axial concentrate port, for treating a broad range of feedwater qualities. www.membrana.com

More Water & WasteWater International Archives Issue Articles