Sludge-to-Energy Options with Decentralised Sewage Reutilisation Needs

With EU landfill regulations tightening, narrower options for disposal of wastewater biosolids can rely on multiple benefits via incineration and energy recovery

By Dr. Mario Mocker, Dr. Ing. Peter Quicker, Prof. Dr. Ing. Martin Faulstich and Dipl. Ing. (FH) Rudolf Bogner

Now, as the EU Landfill Directive has come into force that prohibits landfilling of untreated waste and thus also landfilling of raw sewage sludge, the demand for alternative utilisation and disposal capacities will certainly increase. Also the application of sewage sludge to agricultural land is being considered critical for reasons of preventive soil and consumer protection. The decreasing acceptance and anticipated significant tighter limit values for this utilisation route contribute to the changing situation of sewage sludge disposal. As a consequence the volume of thermally treated sewage sludge has significantly increased in recent years.

Since landfilling isn’t allowed any more, available waste incineration capacities will be occupied also by other waste fractions, such as domestic waste. For cost and capacity reasons, large-scale co-incineration capacities are expected to be expanded. Yet another advisable solution to the problem is a decentralised small incineration plants. As this solution avoids long transport and uses incineration heat for energy-intensive sewage sludge drying, it enjoys ecological and economic advantages.

Germany’s ATZ research institute, under the direction of Prof. Dr. Eng. Martin Faulstich, has developed and tested the sludge-to-energy concept, which is based on pebble heater technology to make decentralised sewage sludge reutilisation a practical reality

Objectives

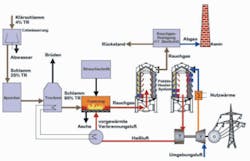

The purpose is to develop and test a new method for thermal utilisation of sewage sludge, which produces at the same time electric and thermal energy. The concept further allows for combined treatment of sewage sludge and other municipal waste, such as horticultural waste, screenings, etc. The core part of the process is the patented pebble heater technology combined with a microgas turbine that enables recovery of electrical energy from the heat of hot flue gas without need for installation of a water-vapour cycle.

Heat from the hot flue gases produced by incineration is transferred into the compressed ambient air by regenerative heat exchangers with radial through-flow (so-called pebble heaters). Under certain conditions and with a small plant size of below MWel, the high heat recovery rates in pebble heaters of up to 98% enable an electric efficiency of around 30% to be achieved. Via heat exchangers the released heat is fed into the dryer.

The concept developed and tested by ATZ is now being brought to the market with a demonstration plant. When the optimisation phase is finished, standardised system modules are planned to be manufactured and commercially utilised. The present plant is designed for an annual sludge volume of about 1.000 bis 2.200 Mg DR.

Pebble Heater & Microgas Turbine

Pebble heater systems work with clocked material layer heat exchangers, called pebble heaters, which are alternately heated with hot flue gas or cooled with ambient air (see Figure 1). Whilst the hot flue gas from the incineration process gives off its heat to the loose material layer of the radial-flow pebble heaters, the gas is partly de-dusted and exits from the plant through the chimney after having passed through another cleaning stage.

During the heating phase of the first pebble heater another already heated exchanger is fed with compressed air (about 4 bar). The compression stage is followed by intermediate cooling, e.g., through heat extraction. As an alternative, intermediate cooling can be achieved by water jets. Whilst streaming through the pebble heater the pre-compressed air is heated to in excess of 900°C and then put onto the entry part of the turbine. Without further addition of fuel, the air in the turbine relaxes and cools down to about 600°C. The turbine drives both the compressor and a generator for power generation.

The gas turbine process is the special form of a low pressure sided recuperated process. In terms of the achievable thermal efficiency moderate pressure conditions between 3 and 6 are especially favourable for recuperated processes with gas turbines. The pressure ratio of such machines meets the requirements of the Huber sludge2energy® demonstration plant. Also the firing temperatures of 900-1,000°C lie within the required range.

The maximum permissible firing temperature is limited by the furnace and pebble heater and must not exceed 1,000°C in order to avoid maceration of easily fusible fractions in the ash and prevent thus blocking of the furnace (e.g., agglutination of the grates). The main difference of operation with air compared to direct firing as is standard is the different dynamics of the combustion chamber and pebble heater and the continuously periodic operation. Different thermodynamic properties of the hot air compared to water containing turbine gas lead to a different power output of the turbine even if the same entry temperature is selected in both cases. For the test plant, a turbine with 100 kW electric power was chosen.

An interesting option is water injection through nozzles into the compressed air, which is frequently practised to increase the performance of gas turbines. The electric power can in this way be increased by about 25%. Water evaporation reduces the temperature of the compressed air from about 200°C to 100°C. This mixture is warmed up when the pebble heater is heated and then introduced into the turbine. The turbine performance is thus significantly increased without an increase in compressor performance.

Although the total process efficiency decreases, this seems to be a very interesting option for the operator, as it enables him to react very quickly and flexibly to peak loads in electrical power consumption and achieve a higher economic efficiency in times with reduced heat demand through increased power generation.

Sewage Sludge Pretreatment

The sewage sludge needs to be dewatered and dried prior to incineration. Innovative compact systems are available on the market for dewatering municipal digested sludge, such as centrifuges.

After intermediate storage, the sludge is fed into a continuously operating dryer by a conveying unit. The feed unit distributes the sewage sludge over the full active width of the upper belt, which transports the sewage sludge into the area with air flow. The process air is heated by means of a heat exchanger, first from the intermediate cooling process of the compression stage of the microgas turbine, second from the relaxed turbine air.

While the air streams through the belts covered with sewage sludge, it’s cooled and loaded with sewage sludge water. The process air is sucked through the dryer by a blower. Due to this underpressure operation of the dryer, there’s no substantial odour annoyance caused. The blower delivers the process air, which is divided into an exhaust air and circulation flow. A two-flap regulator controls the moisture according to the dryer stage. Circulation flow is mixed with the preheated supply air. This mixture as a whole is then heated to up to 130°C as described above.

The exhaust air is directed through a heat exchanger. Heat is extracted from the air flow and re-introduced into the supply air flow by means of a heat exchanger. This type of heat recovery reduces the thermal energy demand enormously. The condensate produced by air cooling is discharged. The exhaust air is further cooled by a washer. Fine dust particles, odours and other components are removed, so treatment complies with German TA standards (Technical Instructions for Air Pollution Prevention).

Combustion

Industrial combustion methods used for sewage sludge incineration, such as story furnaces or fluidised beds, are for cost reasons inapplicable on the target scale. Suitability of grate furnaces for waste incineration plants is also limited as they’re only profitable with a thermal output in excess of 1 MWth due to the high investment costs.

An interesting alternative is biomass combustion furnaces, which require only minor modification to be suitable for inc ineration of granulated dried sewage sludge. Other systems, like a dual-chamber or blow-in furnace may be added to ensure the requested properties are achieved.

Exhaust Gas Cleaning

Reduction of nitric oxides is accomplished by means of well-proven firing measures, such as staged combustion and flue gas recirculation, and selective non-catalytic reduction (SNCR). A combustion temperature of about 950°C provides favourable preconditions for this type of denitrogenisation. Furthermore, the combustion chamber design and design length of the hot gas line between the furnace and pebble heater ensure the residence time is sufficiently long.

Also, other applicable burning technology requirements must, of course, be met, such as the German 17. BlmSchV concerning temperature control, for example. That’s why an additional firing facility is provided for support during plant startup and shutdown.

To remove acid corrosive gases from the exhaust gas flow, such as SO2 and HCl, a dry-sorptive process is applied using a chemically reactive disperse material with a basic component (e.g., Ca(OH)2), which is dosed into the exhaust gas flow. Elimination of unburned hydrocarbons, dioxins, furans and volatile heavy metals is achieved through adsorption of activated carbon. Suitable adsorbent mixtures are commerically available.

To ensure required clean gas values are met, the reaction material must be available in excess. This results in a considerable amount of unused adsorbent. Part of the material is therefore recirculated.

Separation of flue dust and used adsorbent is achieved by a new type of filter elements made of temperature resistant filter material on a clay and glass basis, which can applied under up to 350°C. Contrary to conventional bag filters even temporary temperature peaks, which cannot be excluded in small plants, are therefore no problem. The filter material shows an excellent chemical resistance and has an inorganic coating on the raw gas side to ensure a long life surface filtration at a low pressure loss even when separating very fine dust.

Conclusion

For reasons of preventive environmental and health protection, turning away from agricultural sewage sludge utilisation is unavoidable. The focus is now therefore on thermal sewage sludge treatment as the only reasonable disposal alternative. Besides the anticipated expansion of co-incineration capacities in coal burning power plants, decentralised systems are gaining in importance, as some interesting recent developments give proof.

The ATZ research and development centre in cooperation with Huber is presently bringing to market a system for decentralised thermal utilisation of sewage sludge which produces at the same time electric and thermal energy. The system core is a combination of pebble heater technology with a microgas turbine.

An electric power of 100 kW is planned for the first plant. Treatment capacity of the system is about 1,000-2,200 Mg DR/a. Installation of such a plant gives the wastewater treatment plant operators the independence from the disposal market and long-term cost reliability.

Authors’ Notes:

Dr. Mario Mocker, Dr. Ing. Peter Quicker, Prof. Dr. Ing. Martin Faulstich are all with ATZ Entwicklungszentrum, an independent research institute in Sulzbach-Rosenberg, a town in the eastern part of Bavaria, about two hours away from Munich. Contact:

www.atz.de

Dipl. Ing. (FH) Rudolf Bogner is with Hans Huber AG, of Berching, Germany. It’s part of the Huber Group, a leading supplier of environmental technology with over 50 subsidiaries, branch offices and representatives worldwide. Contact: www.sludge2energy.eu