Common Problems with Pumped Detention

By David Todd

As the cost of development increases, design professionals are called upon to somehow make the land more profitable. Since facilities for mitigating the increase in peak stormwater flows are non-revenue producing, ways are sought to shrink the footprint of the detention facility and free up land for building area and parking spaces. Often this means the detention pond is deeper (with a smaller footprint) or is put underground, allowing the surface to be used for some additional purpose. In either case, having a pond that works strictly by gravity is not always possible. In that case, a pumped discharge becomes necessary.

Stormwater pumping from a detention pond can be a complex situation. Engineers who are used to designing wastewater lift stations must refocus, for the principles of pumping wastewater do not always work for detained stormwater. The key of course is detention. Without that, stormwater pumping and wastewater pumping would be more similar.

The author has had the occasion to design and review stormwater pumping stations associated with detention ponds, and has found a few problems that seem to recur:

- The stormwater pumping station is designed the same as a wastewater pump station, resulting in adequate conveyance but inadequate detention.

- The larger size of stormwater pumps is not taken into account, resulting in construction details inadequate for the intended service.

Designing for average storms

Wastewater Pumping as an Engineer’s Baseline

For sanitary sewage, the goal is to have enough pumping capacity and wetwell volume to move out wastewater in a timely manner, yet not so big that the wastewater could become septic. These goals result in the engineer rounding up everything to be conservative, and to make sure the design has an adequate factor of safety. So if the wastewater flow to a proposed pump station is calculated to be 94 gpm, this might be rounded up to 95 gpm or even 100 gpm. The length of the force main will be rounded up in a similar manner, as will the calculation of the minor losses. The friction factor used to calculate friction losses will be a little rougher than actually anticipated. Since the difference between pump start and stop points in a small pump station is not very great, the design normally is for maximum static head only. The result is that the wastewater pumps will be specified to be larger than truly needed to provide the required service. What should have been 95 gpm at 45 feet total dynamic head (TDH) is specified for 100 gpm at 50 feet TDH. These will be specified as a minimum, and the pump supplier will select the pump that slightly exceeds the specifications. Thus the pumps supplied might be able to pump 110 gpm at 55 feet TDH. For wastewater, this is not a problem: The wastewater is evacuated from the wetwell and sent to the treatment plant a little faster than required. All design conditions are met, the public is served well, and the owner can rest assured that the pump station will perform adequately.

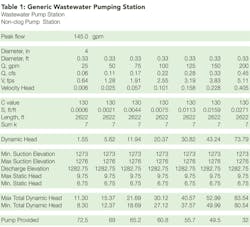

Figure 2: Generic Stormwater Pump Station System Head Curve

Detention Pond Pumping Design Basis

Where stormwater is pumped from a detention pond or underground detention chamber, however, the concept of conservative design (i.e., providing greater factor of safety against failure) must be reversed. For wastewater, the traditional methods of conservative design — making everything “bigger” — works fine. But for pumping from a detention pond or chamber, the design pumping rate is a maximum, so conservative design requires everything to be rounded down, not up. If the design flow rate is 960 gpm, round down to 950 gpm. If the force main length is 725 feet, for calculations round down to 720 or 700. If the friction factor of new pipe is expected to be C=140, keep that, or use 145.

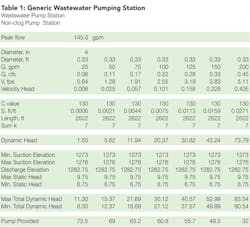

Also, the minimum static head cannot be ignored because it is at the minimum static head that the pumped amount would be greatest, and hence would be the true design condition for pumping. Table 1 and Figure 1 show a typical design of a wastewater pumping station. Since only a few feet separate the maximum and minimum static heads, and since the design objective is to move the wastewater out as quickly as possible, the design will consider only the most severe pumping conditions, the maximum TDH. The pumps, selected to pump a little more than the design requirement, should operate just fine in the narrow range between minimum and maximum TDH.

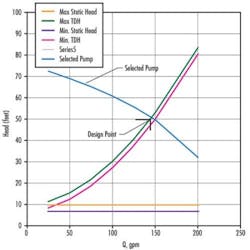

Figure 2 shows calculations and system head curve for a typical stormwater pumping station. With eight feet difference in suction elevations, and with the design condition being to pump not greater than 4.3 cfs (1,930 gpm), a pump was selected to pump a little less than that. The design engineer must use caution, however, not to select a pump that is so far below the design flow that the detention pond (or chamber) is overwhelmed and overtopped. If the pumps pump a little less than the design flow, the detention function is achieved, but depending on how tightly the pond volume is designed to requirements of the design hydrograph, the pond may not function properly.

Construction Details

Relying on wastewater pumping design practice, the engineer often provides construction details for a stormwater pump station. The larger pumps require a larger wetwell, which can exceed the structural limits of wastewater pumping station standard details. A site-specific structural design is needed. The larger pumps will require larger motor starters in larger electrical cabinets. What was a fairly unobtrusive electrical installation for the wastewater pumping station becomes a noticeable eyesore for the stormwater pumping station. Access can also be a factor, since larger equipment may be needed to remove the larger pumps from the stormwater pumping station.

All of this points to the need for a different approach to siting the stormwater pumping station. A small circle on a small scale drawing, often sufficient for the wastewater pumping station, will not suffice for stormwater pumping stations. The author’s experience is that engineers frequently fail to take these differences into account during the design, leaving the problems to be worked out during construction, to the disadvantage of the developer.

Expanded Design Conditions for Detention Pumping

Engineers tend to ignore storms smaller than the design storms for stormwater pumping systems. Typically the local jurisdiction will require the design for rainfall of certain return frequencies, perhaps combination of the 2-, 5-, 10-, 25-, 50-, and 100-year rainfalls. Multiple design points are typically for the purposes of various downstream conveyances. However, depending on downstream conditions, consideration of how best to pump average storms may be advisable.

In the author’s home area of northwest Arkansas, an average rainfall of 42 inches per year might come in twenty to twenty-five rainfall events, averaging less than 2 inches per rainfall. Over a 10 year period, 250 total rainfall events may result in only eight events of more than 3 inches. Pumping systems sized to discharge at the rate of the design storm will over-pump in average storms, possibly 20 times or more per year.

Depending on downstream conditions, this may not be a problem. If pumping directly into a well-defined floodplain or public conveyance such as a ditch or storm sewer, over-pumping during average storms may be acceptable. But if the discharge is to private property, or to a conveyance that is not well defined or maintained, over-pumping during average storms may create a nuisance.

Example Project

Limited topographic relief required that an 80-acre residential subdivision in northwest Arkansas be designed with a deep detention pond with pumped outflow. The alternative was to import as much as $1 million worth of fill for streets and lots, which was not economically viable.

A duplex pumping station was designed to withdraw water from the deeper parts of the pond, and a weir structure provided gravity discharge from the upper parts of the pond. The pumps were designed for the 2-year storm; the weir for all larger storms.

The engineer used classical wastewater pumping design for detention pumping, rounding everything up to be “conservative.” The pumps were designed to provide the design flow at maximum static head. The difference between maximum and minimum head in the pond was more than 10 feet, and the pumps significantly over-pumped at minimum static head. The pump supplier provided pumps that pumped “a little more” than required, which added to over-pumping.

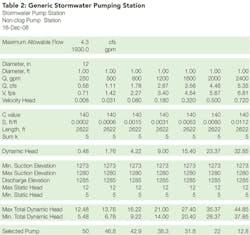

Table 3 provides the author’s revised design calculations with appropriate conservative design. The design pumping rate was 5,000 gpm for each pump, operating simultaneously to separate, parallel force mains. Figure 3 provides the system head curve with the curve of the pumps supplied superimposed, which shows that the pumps will discharge more than that at all levels of the pond, especially at minimum static head.

The over-pumping proved to be no problem for the design storms. The pond had sufficient volume that the design flows were met even though the pumps contributed more than calculated. Even for the 2-year storm, the detention pond volume was sufficient to control flows to the pre-developed amount.

However, during average storms the pumps over-pumped by a considerable amount. Discharge went to a pasture used for grazing. Discharge from the detention pond crossed this pasture through a poorly defined swale for a half mile before entering a public drainage system. The owners of the downstream property have experienced loss of use for grazing, as the higher peak flow during average rainfall, coupled with the increase in total hydrograph volume, keeps the property inundated longer.

Given all the conditions at the site and downstream, the pumping station should have included a low flow pump sized for the average storm. This would have significantly mitigated effects on the downstream property.

Recommendations

Based upon the author’s experience with detention pumping, the following recommendations are given for how to design better pumping systems:

- Understand what factor of safety means when pumping from a detention pond; correctly apply conservative design principles to provide the desired factor of safety.

- Determine maximum pumping capacity, not minimum, in design calculations, and clearly state that this is a maximum on contract documents.

- After pump design is complete, recheck detention pond volume and maximum water surface elevation to make sure pond and pumps work together to provide the detention function required.

- Check shop drawings to verify that the pump supplier has correctly understood the project requirements and is not providing a pump “a little larger” than called for.

- When possible, provide a combination of pumped and gravity discharge.

- Consider the effects of pumping from detention ponds/chambers during average storms, which, although they may be smaller than regulatory requirements, might in fact be more of a nuisance than larger storms.

- Provide construction details that take into account the size of pump required for the project.

About the Author:

David A. Todd, P.E., CPESC, is Corporate Trainer for Engineering with CEI Engineering Associates Inc. He has 35 years of experience in civil engineering, mainly on municipal infrastructure projects.