Generator Set Backs Up new Secondary Treatment Operation

The International Border and Water Commission (IBWC) is installing a new emergency standby power system at the South Bay International Wastewater Treatment plant in California. The system from MTU Onsite Energy will pair with an existing generator and add another 2,000 kW of emergency standby power. The new unit is a 2,000 kW Tier 2 generator set operating at 12.47 kV housed in a specially designed ISO container.

The South Bay International Wastewater Treatment plant is a joint effort between Mexico and the U.S. to treat sewage from Tijuana, Mexico, and eliminate environmental concerns in the Tijuana River Valley just south of San Diego, CA. Built in the late 1990s, the plant is located on a 75-acre site in the U.S. just north of Tijuana.

The South Bay wastewater treatment plant has a capacity of 25 mgd. Its original design consisted of advanced primary treatment followed by discharge via a 4.5-mile pipe extended into the Pacific Ocean near the Mexico-California border. When discharge quality was found not to meet current environmental standards set by the EPA, the International Border and Water Commission (IBWC), the plant’s operator, decided to add secondary treatment to the plant. The project also added another 2,000 kW of emergency standby power.

“The plant hasn’t been expanded in terms of overall capacity. It was originally designed for both advanced primary treatment and secondary treatment, but the secondary facilities were not immediately funded,” said Steve Smullen, area operations manager, IBWC. “Recently, we got the funding, and now we’ve added a biological system, aeration and settling facilities to meet our EPA permit requirements. As a consequence of completing the secondary treatment, we also added quite a bit of additional electrical load to the plant to operate three 700 hp aeration blowers and related equipment. In case of a utility outage, we needed the additional standby generation to handle those larger loads.”

The IBWC selected a new generator package from MTU Onsite Energy to pair with an existing generator at the facility.

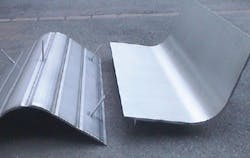

“The treatment plant wanted the new power system installation to physically match that of an existing 2,000 kW generator (from a different manufacturer) that was installed during the original construction in the late ’90s,” said Tim Oergel of W.W.Williams, the local distributor for MTU Onsite Energy. “Getting the two generators to fit into identical packages was a challenge.”

One design issue was the changes in technology over the past 16 years. The new unit is a 2,000 kW Tier 2 generator set operating at 12.47 kV housed in a specially designed ISO container. This newer generator set is EPA certified to meet Tier 2 emissions regulations, whereas the existing generator set was manufactured at the beginning of Tier requirements and was compliant with, but not EPA certified to, the less stringent Tier 1 standards.

In addition to not having modern emissions control hardware, the existing generator drive engine set did not have an electronic governor or other electronic controls to help it synchronize with the new, more advanced MTU generator drive engine. To get the two generators to communicate with each other, the existing generator’s governor was replaced, along with many other controls. The overhaul also included new paralleling switchgear, automatic transfer switches and various communications interfaces.

Unique considerations

“While the MTU Onsite Energy EPA-certified Tier 2 generator set is more fuel efficient and has significantly cleaner exhaust, it also has higher heat rejection that requires a specialized radiator,” Oergel said. “Because we had to match the size of the original 40-foot ISO container, we had to be creative in designing a radiator with higher heat rejection to fit in the same-sized package as the original generator set. The solution was a specially designed radiator from R.F. Partridge & IEA Radiator that was direct-driven through a planetary gear off the engine’s crank shaft. With a larger surface area and greater airflow, the special radiator was able to fit inside the container and still provide the necessary cooling.”

The physical installation of the containers is unique as well. Each containerized generator set is mounted on a concrete pad outside of the plant’s main building. Because the plant is located in earthquake country, both generator set containers are supported by a seismically reinforced mezzanine structure consisting of I-beams connected in crisscross patterns. These structures support the weight of the containers and are bolted to the concrete pad to prevent damage to the generators in the event of an earthquake.

“MTU Onsite Energy was successful in winning the project due to a combination of our EPA-certified Tier 2 emissions rating, good pricing and higher average load-factor capabilities,” Oergel said.

The company’s generator sets are capable of supplying an average 85 percent load factor over 24 hours, compared with the existing unit’s industry-standard 70 percent average load-factor capability.

“That means during extended outages, the MTU generator set can supply 15 percent more kilowatts,” Oergel said.

Installation, final commissioning and load-bank testing were completed in the summer of 2010 to make sure that both units could carry the full plant’s load while operating in parallel.

“Getting the different units to operate together was a challenge,” Oergel said. “There were many sequence-of-operation changes that were needed to make sure both units functioned properly and could carry the load. But now the plant is assured of having emergency power for all its critical loads in the event of a utility outage. That will allow this joint U.S.-Mexico wastewater treatment plant to continue to fulfill its mission of protecting the environment throughout the Tijuana River Valley and Southern California.”

WW

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles