Nitrogen Credit Trading Creates Opportunities for WWTPs

By Bob Dabkowski and Gary Johnson

Nitrogen credit markets, through watershed-based nutrient trading programs, are being set up in various areas of the country. These provide a way to create a market-based incentive for plants that are proactive in the measures they take to control nitrogen output; and to provide both flexibility and a disincentive for those that don't meet their permitted levels of nitrogen output.

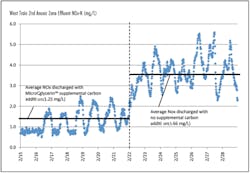

The Stratford, CT, Water Pollution Control Facility (WPCF), which discharges into the nitrogen-sensitive Long Island Sound, is one facility that completed a nitrogen removal upgrade in the first half of 2009. The plant has a four-stage Biological Nutrient Removal (BNR) system with pre- and post-anoxic zones. It is designed to handle 12 mgd, and typically processes an average of 7-8 mgd. During the second half of 2009, the plant did not feed supplemental carbon. Average effluent Total Nitrogen (TN) was 6.3 mg/L, or 379 lbs of nitrogen per day. As a result of being better than their permitted discharge level of 418 pounds per day, the Stratford plant received a modest $32,500 in nitrogen credits during the period June-December 2009.

Plant personnel knew they could improve nitrogen removal performance. At the beginning of 2010, the Stratford wastewater treatment plant began a new program that combined nitrogen control and monitoring technology with supplemental carbon. The use of online nitrate analyzers from Hach along with MicroCglycerin™, a supplemental carbon source from Environmental Operating Solutions Inc. (EOSi), allowed Stratford to improve revenues from credit sales and reduce total nitrogen discharged to levels well below their discharge permit.

The incremental improvements are something that the utility can document and sell through the Connecticut nitrogen credit trading program, turning its nitrogen improvement efforts into profits.

EOSi creates agriculturally derived products to remove nitrogen from wastewater. The company's MicroC™ Premium Carbon Sources were designed to reduce nitrogen by converting it to water and harmless gases. Nitrogen can be removed from wastewater using a treatment process employing methanol, but methanol is toxic, flammable and derived from nonrenewable natural gas. Additionally, methanol prices have fluctuated widely and increased dramatically since 2002. The company's carbohydrate- and glycerin-based products provide an alternative carbon source for denitrification without the safety hazards.

When EOSi needed a way to monitor and record the denitrification improvements its products were providing for its clients, it turned to Hach. The Hach Nitratax™ sc allows operators to monitor nitrate levels in their plants to gauge the effectiveness of carbon dosing.

The plug-and-play probe works with Hach's digital controllers and uses the UV absorption method to measure nitrogen, eliminating reagents, sampling and sample conditioning. A self-cleaning probe and life-long factory calibration ensures accurate measurements and reduces necessary maintenance.

Process Optimization

By adding MicroCglycerin™ and using Hach monitoring technology, the Stratford plant was able to further reduce total nitrogen from the 5.5 to 6 mg/L range down to <3 mg/L - a reduction of 2.5 to >3mg/L in total nitrogen effluent. In mid-winter, New England weather conditions cause cold-water temperatures to reach down to 10 degrees Celsius, typically making it harder to denitrify. With the addition of MicroCglycerin™, nitrogen removal was in the 3-4mg/L range for total nitrogen.Because of Connecticut's nitrogen control program, the plant is now able to track and document this reduction using its five Hach Nitratax sc sensors, and sell nitrogen credits to other plants that do not comply with their permits.

Some simple math to estimate the type of economic incentive in play for the plant takes this estimated reduction of 2.5 mg/L of nitrogen, along with the plant's effluent flow of 7-8 mgd. This leads the EOSi team to estimate a reduction in nitrogen output of 155 pounds a day. Given the value of credits for nitrogen reduction as part of the state program, this amounts to a savings of approximately $570 per day - or $208,000 per year.

The plant won't get final numbers and a detailed analysis of savings and profit realized as a result of this approach until the end of 2010. State regulations require that the plant perform biweekly 24-hour flow-based composite sample lab testing over the course of a year, and compare the results to the plant's permitted output in mass or pounds of nitrogen discharged. As a result, the plant is banking credits for the year, and in January 2011 will go through a full audit and evaluation of their performance.

The Hach equipment has also allowed operations personnel to understand the variation in nitrate levels throughout the day and by day of the week (weekday vs. weekend). Work is currently underway to automatically adjust the MicroCglycerin™ dosage rate according to flow and/or nitrate levels entering the 2nd anoxic zone through the plant's SCADA system. These adjustments are expected to further improve nitrogen removal performance while minimizing chemical expenditures.

The system is likely to prove even more valuable in the future, as the nitrogen removal process is further optimized and as the output of nitrogen permissible will become more stringent on an annual basis, with reductions in output legislated to step down, year by year, through 2014. WW

About the Authors: Bob Dabkowski is a Wastewater Specialist for Hach Company and a Licensed Colorado Wastewater Operator. He is the author of several papers, articles, and application notes concerning wastewater treatment. He may be contacted via e-mail at [email protected]. Gary Johnson is the Director of Process Engineering at Environmental Operating Solutions Inc. He draws on nearly 30 years in the wastewater industry and is licensed as a professional engineer. He may be contacted via e-mail at [email protected].

Hach is an exhibitor at the WEFTEC.10 event and can be found at Booth No. 1615

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles