The AquaNereda Aerobic Granular Sludge Technology is an advanced secondary wastewater treatment process that utilizes the unique attributes of the granular biomass to perform biological treatment. The technology operates on an optimized batch cycle structure that creates the proper conditions to develop and maintain granules: large, dense microbial aggregates displaying as particles greater than 200 microns in diameter that perform biological nutrient removal (BNR) and display exemplary settleability relative to conventional activated sludge (CAS). Figure 1 provides a visual comparison of AGS and CAS samples after a five-minute settle time. The settling properties allow the system to operate at high mixed liquor suspended solids (MLSS) concentrations in excess of 8 g/L without a loss in aeration efficiency due to the granular nature of the sludge. AquaNereda can therefore provide a significant reduction in both footprint requirements (up to 75%) and energy demand (up to 50%) compared to a conventional technology.

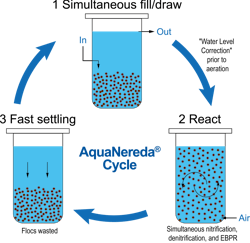

Aerobic granular sludge (AGS) possesses inherent BNR capabilities as the layered microbial community of the granules enables simultaneous nitrification/denitrification and enhanced biological phosphorus removal (EBPR) to occur within the granular biomass. This technology therefore eliminates the need for clarifiers, carrier media, and return sludge pumping stations, as well as selectors or separate compartments for plants looking to achieve BNR.

For more information on AquaNereda technology, visit www.aquanereda.com or contact Aqua-Aerobic Systems directly at 815-654-2501.