How to Select a Pump with the Highest Efficiency

By Allan R. Budris

My previous columns on the subject of pump efficiency have mainly dealt with the interaction between the pump and system, pump controls, and how to improve the efficiency of an existing pump system, which are all important consideration. However, in this column I would like to concentrate on the pump and provide an overview on how to select a new pump with the highest efficiency for the application. In so doing, it is important to understand the individual factors that affect pump efficiency.

The key factors that impact pump efficiency are:

1. Operation over a pump's range of flow rates, as a function the pump best efficiency flow rate. The system Head-Capacity curve dictates where a pump will operate on its H-Q curve (the pump will always operate at the intersection between the pump and system H-Q curves), and how far it will operate away from its best efficiency flow rate. The best way to insure that a pump will operate close to its bep (once the system H-Q curve has been established) is to:

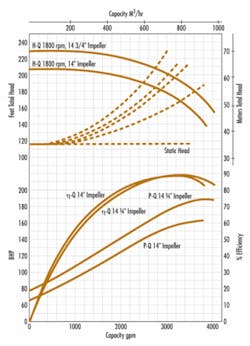

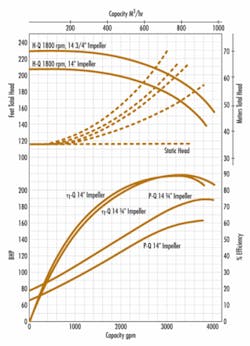

a. Select a pump, impeller trim, and/or speed that will closely match the system H-Q curve, near the pump bep (see figure 1). You must determine the actual power and efficiency impact for the possible impeller trims and control means for various pump sizes, to find the best match.

b. For a varying system H-Q curve, consider a Variable Speed Drive (May 2008 Column), with or without hybrid/bypass control (Aug 2008 Column), to keep the pump operating close to its bep.

c. For systems with large changes in flow and/or head, consider multiple pumps, operating in parallel (Nov 2008 Column), or separately. It may be more efficient to include a smaller pump for every day operation, and a separate larger pump for the few times when much higher heads and/or flow rates are required.

• When considering multiple pumps for parallel operation, it must be realized that, since the bep efficiency of the individual pumps will be impacted by their flow rates, by reducing the flow rate of the individual pumps, you are reducing their maximum obtainable efficiency, as shown in figures 2. So it becomes a trade-off between keeping the flow rate of the individual pumps high, versus staying close to the pump bep, for maximum efficiency.

d. Another efficiency factor to consider when selecting a pump is the operating speed and how it impacts the pump "Specific Speed" (see September 2009 column). As shown in figure 3, maximum obtainable pump bep efficiency occurs in the specific speed range of 2,000 to 3,500, with higher speeds (and flow rates) increasing specific speed, and higher heads lowering the value. So, if higher or lower speed selections (say 1,180 RPM vs. 1780 RPM), higher or lower flow rates, and/or higher heads move the pump closer to or further away from this optimum specific speed range, there will be an impact on the pump bep efficiency.

As an example, if the application calls for a low single pump Specific Speed value of 500 - 1200 or lower, then by adding additional impeller stages, which reduces the head produced by each stage, the Specific Speed value of each impeller stage is increased. This then can result in a substantial increase in the efficiency of the pump (see figure 4). This is one of the advantages of vertical turbine pumps, which can change the number of impeller stages with little effort.

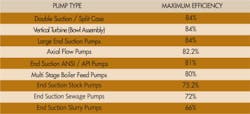

2. Another factor that impacts the obtainable pump efficiency is the "Pump Type" (see Table 1). Various pump types require design compromises for their intended application, such as large flow passages to handle large solids, which will not allow optimum hydraulic design. Further, increased internal wearing ring clearance to avoid contact (such as with API pumps) increases internal flow leakage, which reduces the maximum obtainable efficiency. Finally, special options, such as larger impeller eyes for lower NPSHR and/or lower impeller vane angles and/or number of vanes to achieve rising H-Q curves to shutoff on low specific speed pumps, can reduce the obtainable pump efficiency.

3. Trimming or reducing the impeller diameter will reduce the efficiency of almost all centrifugal pumps. However, it is more efficient to trim the diameter of an impeller than to drop the pressure by throttling a discharge valve, or to operate further away from the pump bep with a full impeller diameter.

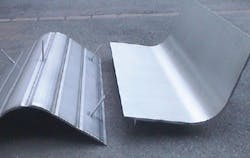

4. Surface roughness (see May 2008 column) has a definite impact on pump efficiency, with the magnitude of the affect dependent on the degree of roughness, pump specific speed and size. Generally, surface finish improvements for new pumps (by polishing or coating waterways) are economically justifiable for small and low specific speed pumps, with efficiency improvements of 2% to 5% possible for specific speeds below about 1,000. Polishing or coating the outside of the impeller shrouds will, however, also reduce the developed head of the impeller, since these outer surfaces contribute (somewhat) to the head generation.

5. For pumps below about 15 hp, mechanical losses, such as from bearings, lip seals, mechanical seals and misalignment, can have a noticeable impact on pump efficiency. So adding a double mechanical seal or dynamic seal (May 2010 Column) to a small pump can reduce the obtainable efficiency.

6. The liquids handled, such as higher viscosities and/or slurries, can also have a detrimental effect on efficiency. The Hydraulic Institute Standards provide viscosity correction curves, while the pump supplier should be consulted when making efficiency corrections for slurries.

Conclusions:

As can be seen above, in order to achieve the maximum efficiency for an application, many factors should be considered, such as % bep flow, flow rate, speed, head, specific speed, pump type, parallel pumps, impeller trim, surface finish, mechanical losses and the liquid pumped. So, more than one option should be evaluated in order to optimize this process.

References:

- "Pump User's Handbook - Life Extension", Allan R. Budris, P.E., and Heinz P. Bloch, 3rd Edition, 2010, The Fairmont Press.

- "Centrifugal Pumps for Nomenclature, Definitions, Application and Operation", ANSI/HI 1.1-1.5-1994, American National / Hydraulic Institute Standard.

About the Author: Allan R. Budris, P.E., is an independent consulting engineer who specializes in training, failure analysis, troubleshooting, reliability, efficiency audits and litigation support on pumps and pumping systems. With offices in Washington, NJ, he can be contacted via e-mail at [email protected].

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles