Automated dam monitoring improves Yuba Water Agency’s risk assessment

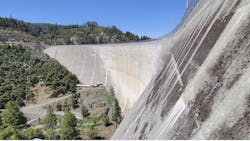

Situated in the Yuba County foothills along the edge of Tahoe National Forest on the North Yuba River, New Bullards Bar Dam is a 645-foot-tall concrete arch dam. It is the second tallest dam in California, and the fifth tallest in the United States.

The dam has a capacity to hold 1.19 cubic kilometers of water, which forms the New Bullards Bar Reservoir that provides flood control and serves as a popular recreation area. The reservoir also ensures colder downstream river temperatures for fishery enhancement.

Owned and operated by Yuba Water Agency, the dam was constructed in 1970 as part of the Yuba River Development project, which was aimed at reducing flood risk, generating clean hydropower, and ensuring a reliable water supply for county residents and the environment. Committed to dam safety and efficient, reliable infrastructure operations, Yuba Water sought to modernize the dam monitoring system by collecting continuous, real-time operational data.

With multiple monitoring prisms and pylons, the new automated system provides real-time monitoring of the movement of the dam structure as time passes and it is exposed to different natural elements. The project has improved dam safety by allowing for quicker detection of abnormal deformation of the dam, which could result in more timely investigations and possible risk reduction measures.

Addressing site survey, security and safety risks

Implementing the new monitoring system involved performing drone surveys and installing automated survey equipment for detecting 3D deflection, as well as monitoring any propagation or deformation of the dam structure.

The project required establishing local survey benchmarks, installing reflective survey targets across the dam face, and building a secure enclosure house to protect the automated motorized station.

Challenges faced by the project team included securing permitting and approvals for drilling and installing devices directly to the dam, as well as the engineering and construction activities necessary to build a dedicated enclosure for survey equipment at a location with visibility of the entire downstream dam face. Compounding these issues was the steep terrain around the dam, accessible only via a narrow, restricted road.

The dam’s previous monitoring system posed safety hazards, requiring time-consuming, costly and hazardous manual data collection that spanned only a portion of the dam. To reduce personnel safety risks, Yuba Water wanted to implement a more cost-efficient, safe, and comprehensive automated monitoring system, eliminating manual surveys.

They sought to implement an integrated reality modeling and digital twin solution to remotely collect and visualize real-time data and automate alerts and reports of potential issues, while securing the on-site station equipment necessary to perform the digital monitoring.

Leveraging software to automate dam monitoring

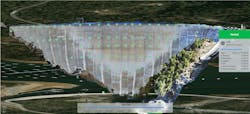

Yuba Water worked with Niricson, an iTwin Ventures portfolio company, to capture a 3D reality mesh from thousands of drone-captured images and process it in iTwin Capture, a software from Bentley Systems.

Yuba then uploaded the photorealistic model to Bentley’s cloud-based iTwin IoT platform, where the model was associated with the monitoring devices to visualize the sensor data in real time.

“Bentley software was chosen because of its ability to collect monitoring data remotely and automate analysis and alerts based on predetermined thresholds,” said Truong. “The location of the dam is quite remote, so the ability to track the stability of the structure remotely is very valuable.”

The digital twin visualizes, analyzes and provides automated decision support and thorough dashboards and reporting on structural integrity and reliability of the dam.

Using Bentley’s iTwin IoT to incorporate sensor data within the model, Yuba Water can view the sensor locations within the geospatial context of the dam, determine if they have reached any alert thresholds, and monitor deformation and propagation of the dam structure. In addition, the team can now track direction of deformation using slope stability and graph sensor data directly on the digital twin without having to utilize multiple software platforms.

The software allows Yuba Water Agency to track events, provide timely alerts and report to stakeholders, all in one platform. It also provides peace of mind within a secure system, locking access to the total station for the majority of the time that live monitoring is not occurring.

Digital twin optimizes operations, ensures safety

“[The] Bentley solution has reduced the cost and time associated with getting data from the monitoring system,” said Truong.

The original legacy system took approximately one week to get a data point from a target and cost USD $5,000 for each manually collected data event. The new cloud-based system can collect a data point from over 80 prisms twice a day, and make it immediately accessible to the authorized users at no extra cost other than the purchase of the iTwin software.

The new solution has saved hours every week and improved workflows and productivity, all while eliminating risky on-site visits. Moreover, the digital twin allows the team to closely monitor the structure, helping to ensure public safety and protect the surrounding environment.

Using iTwin IoT, the dam can also be monitored more closely and quickly during heavy rainfall and seismic events.

“For Yuba Water Agency, there is nothing more important than public safety. Investing in a real-time, automated total monitoring station at New Bullards Bar Dam significantly improves our monitoring capabilities and is testament to our continued commitment to public safety and infrastructure resilience,” said Truong.

PROJECT SUMMARY

ORGANIZATION: Yuba Water Agency

SOLUTION: Survey and Monitoring

LOCATION: Camptonville, California, United States

PROJECT OBJECTIVES:

To increase operational efficiency and reliability of New Bullards Bar Dam.

To implement a digital automated dam survey and monitoring system.

PROJECT PLAYBOOK: iTwin Capture, iTwin IoT

About the Author

Sandra DiMatteo

Sandra DiMatteo is the industry marketing director for water infrastructure at Bentley Systems. She has more than 25 years of experience in reliability and asset performance management software and asset lifecycle information management.