Aude Giard: The Digital Water Connector

Aude Giard was appointed as the chief digital officer at VWT to help make sure water treatment technologies are connected. Here she explains why she believes smart water, IoT and Big Data are more than just buzzwords.

By Tom Freyberg

In a world of sludge, excessive acronyms and testosterone-filled boardrooms, Aude Giard is a breath of fresh air. Radiating technical competence but delivered with a friendly and warm persona, Giard is exactly what the industry needs. She is the chief digital officer (CDO) of Veolia Water Technologies (VWT), a role which is new but, along with chief information officer (CIO), becoming common within utilities.

Connecting Technologies

Giard’s role was only introduced 1.5 years ago by Veolia, in recognition of the need for someone to focus on the digitalization of the water market.

Interestingly, a lot the smart water/digital discussions have been focused on the utility water network side — improving how water reaches customers after treatment. However, with VWT as a manufacturer focused more on the treatment side of the business, Giard has been tasked with looking into how technologies can all be connected.

She originally started with VWT 10 years ago, after spending time as a consultant on the energy markets.

“I worked really early on this digital transformation, starting with the digitalization of IT assets and then moving into improving the services we provide to our customers,” she said.

Technology is changing the way water does business.

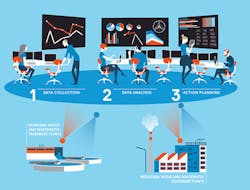

“The role is quite challenging in the sense that we are creating something new that relies on the core business of the company. It covers both the technical aspects and more business-oriented aspects. Our ambition is to connect worldwide all treatment technologies in order to help our customers better operate them. This ranges from chemical dosing to energy consumption and environmental compliance.”

Visit any major water exhibition and it’s clear the offering from technology companies is changing. Membrane companies, for example, now offer software packages alongside the actual hardware, to help plan and see how the modules operate in real-time conditions. Manufacturers have evolved beyond the point of simply selling the equipment — they need to provide more.

“This is a trend we are seeing but it’s also what we see coming from our customers,” she said. “They are less and less interested in the asset and more interested in the outcome of the asset…servicetization is a trend that utilities are following.”

Digital Water Plant

Earlier this year, VWT launched its AQUAVISTA™ digital services software. The cloud-based platform allows municipalities and industrials to “manage their water treatment systems in a much smarter and more efficient way over a period of time, letting them focus on their core business.”

One utility has been developing what has been called a “digital water plant.” Danish environment, energy and climate company BlueKolding A/S covers the municipality of Kolding. Working with Veolia subsidiary Krüger A/S for over 10 years, the utility is seeing increased security benefit from the software being cloud-based.

In 2012 and 2013 three satellite wastewater treatment plants (WWTPs) were furnished with AQUAVISTA Plant. The purpose was to ensure a stable operation and maximize the operational savings by providing the staff with the relevant software for optimizing the plants.

In 2017, BlueKolding extended its software solution on the new cloud-platform AQUAVISTA Plant by the integrated control of Agtrup WWTP, together with the sewer network for the City of Kolding as well as the three satellite WWTPs.

Over the years BlueKolding has experienced compliant operation under all conditions by active online control with far less manpower than is required for visits to the satellite plants.

“It has helped us to lower the costs of our operations and helped us to have a better carbon footprint as well,” said Per Holm, CEO of BlueKolding. “And now it’s cloud-based and that means that our data security is on a very high level and that’s very important to us.”

AQUAVISTA™ digital services software is a cloud-based platform that allows municipalities and industries to efficiently manage their water treatment systems.

Buzzwords or Reality

The water industry has been hearing for a while that Big Data, the Internet of Things (IoT) and Water 4.0 are going to radicalize the business. Yet day-to-day operations continue regardless; with some operators integrating these technologies and others not. It raises the question of whether many of these phrases are just buzzwords or indeed game-changing?

“They are here to stay for a while,” said Giard. “What I see, from what the customers are telling us and within the company, is that these topics are being taken seriously. They are not buzzwords anymore. They are being taken at a strategic level.”

Digitalization presents an amazing opportunity as a way to service clients, she noted, but there’s definitely an educational path to customers. “These concepts need to be explained and time taken with customers and within our company.”

Aude Giard

Giard concluded: “Utilities are all getting organized in order to reinvent their business models and the way they create value, not just in a silo mode anymore but as an ecosystem of partners, cogenerating value to customers.”

It’s a matter of adaptation, she added. “You either adapt or you die, right? It’s very Darwinian.” WW

About the Author: Tom Freyberg is an experienced environmental journalist, having worked across a variety of business-to-business titles. From 2010 to 2018, Freyberg served as chief editor of PennWell’s global water group, developing international partnerships and overseeing digital developments for Water & Wastewater International magazine. He is an English graduate from Exeter University, and completed his PMA journalism training in London.

Circle No. 245 on Reader Service Card