Process Optimization Takes Energy Audit to Next Level

By Steve Bolles and Tom Hazlett

Talk to any public works official or plant manager and you'll find that energy efficiency is a key topic of concern for the water and wastewater facilities they oversee. To address that concern, communities often turn to an energy audit - a useful tool that focuses on understanding a facility's electrical use and heating needs and identifying methods to improve energy efficiency.

That's an important beginning - but it's just a beginning, particularly for an evaluation at a treatment facility, where the best way to truly maximize energy savings is to understand how the facility treatment processes and collection system pump stations can be optimized using a systems approach for more efficient operation. Although this approach is initially focused on energy efficiency, the comprehensive nature of this type of evaluation also can include the benefits of maintenance, chemicals and other operational savings that can support the project from a life cycle cost perspective. In addition to the technical evaluation, this approach also includes key management initiatives that integrate energy efficiency into all aspects of facility operations.

In other words, the community looking to gain the most for its energy evaluation investment will be able to do so by undertaking a comprehensive system-wide audit to answer the question, "How could this facility be run differently to save energy and can this initiative be integrated into facility operations?" The town of Billerica, MA, is doing just that.

Traditional energy evaluations or audits can take many forms. However, when undertaken at wastewater treatment facilities, they often do not provide a detailed process system approach to energy savings. Another approach is a traditional engineering evaluation that provides a comprehensive evaluation of process systems but often lacks both measured energy use data and an approach that focuses on energy savings. As shown in Figure 1, Billerica combined these two approaches to provide an ideal balance to optimize facility efficiency.

Project Overview

Billerica is a mixed residential and industrial community of 40,000 located 20 miles northwest of Boston. The town's 5.4 mgd treatment facility accepts wastewater from homes, businesses, and industries connected to the town's sewer system. The wastewater collection system includes 185 miles of gravity sewer lines, force mains, and 25 pumping stations. It currently accommodates 75% of the population, and the town is in the process of expanding the system to handle 90% of the population. This expansion required the town to complete a Comprehensive Wastewater Management Plan including a Comprehensive Plant Evaluation. Both of these planning studies recommended completion of an energy audit to help optimize operation of the existing facilities.

Billerica's energy evaluation addressed all buildings and systems at the wastewater treatment facility and included a site review of the 10 largest collection system pump stations. The team conducting this effort was comprised of facility staff, Process Energy Services, and Woodard & Curran. Together they completed extensive data collection, detailed process analysis, and energy use projections for proposed system improvements.

As part of the evaluation, the team used monthly energy and process data to evaluate facility performance using EPA's wastewater Energy Star Portfolio Manager program. This program allows facilities to enter energy and process data to compare their facility with other similar plants to score overall plant energy efficiency. Results from the program indicated a performance rating of 81 for the Billerica wastewater facilities (based on a scale of 1-100), which indicated that improving facility efficiency would be challenging for the team.

The evaluation included the following key steps:

- Review energy use and rates;

- Develop energy balance based on measured data;

- Conduct equipment efficiency tests;

- Collect process data and complete process system modeling and analysis;

- Review heating, ventilating, and lighting systems; and

- Prepare cost benefit analysis.

The team also reviewed O&M manuals, previous evaluations, and staff input to determine the original design intent and operational challenges.

Pump Stations

The team conducted site visits and performed equipment testing at all major pump stations. However, before focusing on component efficiency, the team first looked at overall system efficiency and energy use patterns. Thanks to that initial focus as part of the Comprehensive Wastewater Management Planning Effort, the team determined that installing gravity sewer bypasses could eliminate three collection system pump stations. This recommendation had worthwhile energy savings benefits, but the additional future capital cost and maintenance savings provided an even greater incentive to pursue this system improvement.

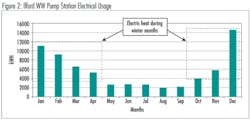

In addition, the detailed energy review of the collection system pump stations found that the majority of energy use for several of the pump stations was for electric heat instead of pumping. A sample of seasonal energy use for one of the pump stations is shown in Figure 2.

This simple analysis resulted in simple low-cost improvements that had a significant impact on reducing energy costs.

After the energy use analysis, the team evaluated pump system efficiency using the Department of Energy's Best Practices Program's Pump Systems Assessment Tool (PSAT). This software tool uses field measurements to evaluate pump system efficiency. Although the most powerful use of the tool is to evaluate the potential energy savings of system opportunities, it also provides a direct indication of pump efficiency with an "optimization grade" that is based on how it compares with similar pumps. As noted in Figure 3, the PSAT summary for the Richardson Street Pump Station, improving the pump efficiency for this station would result in approximately $4,700 in annual energy savings.

Treatment Facility Process Review

As part of the treatment facility review, power for all major equipment was measured with portable meters. This data was summarized in the equipment energy balance and combined with relevant process and operational data over a selected 12 month time period to establish a system baseline.

With the aeration system representing 50% of the total facility energy use, this process was a key area of focus. To evaluate aeration system energy savings opportunities, process data (airflow, blower hours at high/low speed and dissolved oxygen levels) was needed for the analysis. Although the collection process was time consuming since it was only available in manual logs, it was a critical part to establish an accurate baseline for the system. This additional effort proved to be worthwhile to also qualify the project for utility incentives.

Once the data was collected, the team developed an aeration system model to evaluate potential savings. The model was designed to evaluate individual projects offering the potential for energy savings, and then provide the facility with a prioritized list of improvements. These improvements included:

- Repair air leaks in distribution piping;

- Improve the post aeration controls (part of aeration distribution);

- Improved dissolved oxygen system controls; and

- Replace the existing positive displacement blowers with new turbo blowers.

In addition to the above improvements Billerica was also considering replacing the existing ceramic diffused aeration system with a membrane fine bubble system. By using the aeration model, the team found that the interactive savings for this improvement did not support the project. This information helped the facility staff determine the true savings of each improvement instead of relying on general savings estimates that are often provided with a traditional engineering evaluation.

In addition to identifying new energy saving projects, the evaluation also provided energy use data that documented areas of high efficiency for existing systems and verified savings for previous facility improvements. Some of these included.

- Existing operation of the return activated sludge pumps equipped with variable frequency drives proved to be very efficient.

- Over the previous 12 months, the facility had continuously improved the performance of new dewatering equipment by increasing the % feed solids, which had a corresponding effect on higher cake solids and resulted in lower recycled flows and sludge disposal cost savings.

- Documented energy savings of $75,000 annually realized by taking the compost system off line.

- Providing a breakdown of energy use for the new CoMag™ tertiary treatment system to highlight energy saving features and provide projected energy use data to help optimize system operation.

Treatment Facility Building Systems

The evaluation included a review of all HVAC and lighting systems and energy data for the site buildings. Instead of using the existing energy use to justify large-scale heating system improvements, the team focused on ventilation and temperature system requirements for each building. This effort identified opportunities to maintain lower building temperatures in unstaffed process areas to realize immediate savings before considering more costly heating system upgrades.

Identifying Projects, Establishing Priorities

As cost savings projects were identified, each measure was prioritized based on ease of implementation, cost effectiveness, and the ability for each project to support subsequent measures. Projects with a simple payback of less than one year or recommendations that included energy practices without defined savings/costs were designated as operational measures (OMs). Projects with a simple payback that exceeded one year were designated as energy conservation measures (ECMs), and improvements that would reduce energy costs without reducing energy consumption (i.e., alternative energy supplier and rate schedule changes) were designated as energy supply measures (ESMs).

The evaluation identified annual energy savings of $142,028, which represented 28% of the facility's total energy use. Based on an estimated total project cost of $1,020,177, the project had a simple payback of 7.2 years.

National Grid Support Moves Project Forward

Funding the evaluation and follow-on work was a challenge for the town. The project team identified funding through National Grid, which also served as the audit's sponsor, picking up half the cost of the audit. National Grid determined that three of the projects recommended as a result of the audit were eligible for financial assistance in the form of a grant. With an estimated project cost of $850,000, and National Grid's commitment to fund just over $183,000, the project's simple payback was reduced from 7.2 years to 6.4 years.

Conclusion

Based on the team's comprehensive approach, the evaluation identified energy savings improvements that will bring the facility to an even higher efficiency level. Based on the EPA Energy Star Portfolio Manager, which reflected a grade of 81 when the study was begun, the facility's grade is expected to increase to 91 after the improvements have been completed.

In addition to energy cost savings, staff have also adopted energy management practices into facility upgrades and operational practices. These improved practices will realize environmental benefits and reduce maintenance costs with the investment in new equipment and controls.

WW

About the Authors: Steve Bolles, CEM, is president of Process Energy Services, Londonderry, NH. He has 20 years of experience designing, constructing, and optimizing water and wastewater facilities. He can be reached at [email protected]. Tom Hazlet, P.E., is a project manager at Woodard & Curran, Dedham, MA. He focuses on water, wastewater, and stormwater projects for clients in the public and private sectors. He can be contacted at [email protected].