Adding a new dimension to water treatment plant designs

Key Highlights

- 3D point scan technology uses specialized cameras with photogrammetry, laser measurement, and GPS to create high-resolution, accurate 3D models of treatment plant sites.

- The technology reduces the need for multiple site visits, photographs, and manual measurements, saving time and minimizing errors in design documentation.

- It is especially beneficial for existing plants with physical constraints, complex layouts, or remote locations, enabling precise placement of new equipment.

The addition of new advanced treatment systems like membrane technologies requires the production of design documents locating the new equipment within available space at the water treatment plant. The production of these design documents can benefit greatly in terms of accuracy and efficiency with the application of 3D point scan technology. While there are upfront costs associated with collecting site scans, water treatment plant operators may find the design delivery benefits outweigh the effort and expense.

Overview: Treatment plant design process

The efficient and accurate production of design documents is essential for upgrading or adding advanced water treatment systems that incorporate membrane technologies such as reverse osmosis (RO) and ultrafiltration (UF). Specifically, process mechanical drawings are needed to show the piping, valves and equipment that treat the source water. Decades ago, these drawings were prepared by hand on physical, two-dimensional mylar sheets. As technology progressed, computer-aided drafting allowed drawings to be created in a data environment, but initially still in 2D. Advances in computing processing eventually led to the ability to create 3D computer models. Today, further incremental improvements continue to be made in the 3D design process.

Although the drawing production space has experienced rapid advancements over the last 30 years, the role of the design engineer has stayed relatively constant. While CAD models are 3D, final drawings and the engineer’s ability to review and markup drawings still largely exist in 2D space. When working in existing plants for expansions or upgrades, engineers must travel to the facility, take photographs and hand measurements, and record findings in notebooks. If the site is remote from the engineer’s location, this work method can be inefficient — requiring calls or return trips to collect additional information needed for the design that weren’t captured on any previous visits. This process extends to as-built drawings which are typically produced by markups to the original plans made by the installing contractor. This process is prone to potential errors or omissions and could be problematic to rely on for future work at the site.

Design advancement: 3D point scan technology

Into this space stepped a relatively new technology that has been supported by the recent increase in computer processing power, known as 3D point scanning. The technology uses a specialized camera that includes three main elements:

- Photogrammetry

- Accurate laser measurement

- GPS location

In short, it’s a specialized camera and CAD software package that allows the collection of high resolution, dimensionally accurate images that can then be overlayed with conventional CAD design software. It has great benefits for process mechanical design, particularly in upgrades or expansions of existing plants.

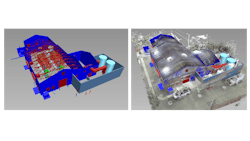

Here’s how it works: The camera spins rapidly during image and data collection and is able to collect high-resolution 3D graphics composed of millions of data points collected every minute during the scanning process. The GPS information is collected at the time the scans are taken and allows multiple scans at various points in the facility to be joined together into a composite 3D image. The camera works in normal line-of-sight within a distance up to 100 yards. Computers employed to process the data directly from the camera use specialized software and high-powered processors. Conventional laptops and similar devices do not have the processing power to load the captured scans directly. Rather, CAD designers can use the collected scans and overlay new 3D components over the images using conventional 3D design software. This effectively creates new, less complex 3D drawings.

The technology is particularly powerful when used in designing treatment facilities with advanced water treatment systems. It removes the need for accurate as-builts at existing facilities as the information can be collected directly and with high accuracy. It captures components that exist in the physical plant space that often aren’t typically shown on mechanical plans and as-builts. The collection of 3D point scans may be essential for any facility considering modification or expansion. It can also be useful for cases in which an overall site is bound by physical constraints —for instance, sites with existing process equipment in the proposed installation area for the new equipment or sites with existing process buildings or pads for installation.

Putting the 3D design technology to work

Three recent water treatment plant projects showcase why and how the 3D point scan technology helped support the mechanical process design, including for facilities located farther from the engineering team, sites that are more complex, or those requiring a detailed analysis of various system alternatives.

First, an existing treatment plant in Central California sought to replace some aging equipment and improve access.

One of these items was the facility’s existing cleaning and neutralization system for its membrane treatment process. Scans of the facility were essential since the plant was located nearly 200 miles from the engineers working on the mechanical design. Early in the project, the design team made several trips to the facility to take pictures and get necessary dimensional information. However, a 3D point scan of the project work areas allowed the team to efficiently and effectively create a CAD model of the new equipment that would integrate well with the existing facilities, thus leading to the final design.

A second example was at a large water treatment facility in Southern California. The local utility wanted to evaluate the potential implementation of energy recovery devices to its existing RO membrane trains. The facility’s pipe gallery was congested with existing process piping, electrical panels and structural supports. It was determined that a 3D point scan would be required to accurately capture site details not discernable from plant 2D design and record drawings. Since it was an initial feasibility investigation, the engineering design team used the 3D point scan results and integrated proposed new piping directly into the base 3D CAD model. This allowed the team to quickly and efficiently determine the best routing alignments for the new piping, thus saving time and costs.

The last is another feasibility level investigation for a second utility in Southern California. The project aimed to evaluate several different treatment options for removing perfluoroalkyl substances (PFAs) from the source supply. The design team needed to accurately assess the ability to locate new treatment system equipment within existing structures and relied on a 3D point scan of the facility to provide the most reliable data. The scan allowed the team to rapidly and accurately develop preliminary layouts for the treatment systems under evaluation. This helped ensure that all potential costs were accounted for in the analysis of the alternatives by showing where proposed new equipment might interfere with existing structures.

Considerations for treatment plant operators

The 3D point scan technology provides operators and owners with an affordable way to accurately capture the physical details of a site or space intended for the addition of new treatment equipment. This information ensures the production of accurate construction drawings that reduce the likelihood of change orders.

About the Author

Alex Wesner

Alex Wesner, P.E., is a Fellow Environmental Engineer at Brown and Caldwell, a full-service environmental engineering and construction services firm. As a chemical engineer, he brings more than 30 years of experience in the design of advanced water treatment systems incorporating membrane technologies like ultrafiltration, nanofiltration and reverse osmosis. His work includes preparing piping and instrumentation drawings, technical specifications and process mechanical drawings. He is based in Brown and Caldwell’s San Diego office and previously was co-owner of Separation Processes, Inc. (SPI), which Brown and Caldwell acquired in June 2025.