Beyond the Initial Investment: A Look at Water Service Line Costs & Best Practices for Lead Service Line Replacement

Water utilities and systems are mandated and regulated to deliver safe water while ensuring financial responsibility using ratepayers and public funds. It is in the best interest of both the utilities and their customers to make prudent financial decisions throughout the infrastructure’s life cycle and implement installation best practices when replacing lead service lines with copper.

Evaluating the long-term value and durability of water service line materials

On average, lead service line replacements across the country can range from a few thousand dollars to more than $10,000. A standard estimate for the material and installation of a 65-foot-long service line is $5,000. Copper service lines cost an average of $286, compared to $46 for plastic pipe. However, this $240 difference per service line means the initial savings from using plastic are less than 5% of the total replacement cost.

These savings might seem significant for utilities undertaking thousands of service line replacements, but they do not tell the whole story. A study from Irwin P. Sharpe & Associates, titled “Undergroundwater Service Lines – Material Usage Trends 1965-2009,” highlights copper’s durability and long-term value compared with plastic for underground water service lines.

The full life cycle costs of these materials reveal that the lower initial price of plastic can lead to higher expenses over the life of the service line due to the increased likelihood of repairs or replacements.

This became evident during the construction boom of the late 1980s and 1990s when municipalities opted for plastic pipe for water service lines. As construction continued into the early 2000s, the drawbacks of plastic, including leaks and water loss, became more apparent. Consequently, utilities and municipalities began reverting to copper pipe for its longevity and overall value.

Life cycle cost and total cost of ownership

It is important to consider the total life-cycle costs expected throughout a service line’s lifespan, including potential salvage value at the end of its use. Copper, which has been used as a service line material since the 1930s, has consistently demonstrated a long lifespan, typically lasting 75 to 100 years. In contrast, plastics can have a lifespan between 25 to 40 years, although some studies suggest longer lives.

Over a 75-year period, a copper system would only need to be installed once, whereas a plastic system may require installation and then two replacements at the 25-year and 50-year marks. Additionally, at the end of its service life, copper service lines have a scrap value, often fetching between 80 to 90% of the value of new copper, based on weight. With a high recycled capture rate, this adds an economic advantage to choosing copper over plastics for service line materials for a true circular economy.

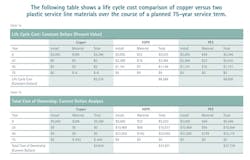

The analysis in Figure 1 uses the following common assumptions

- Installation cost: $5,000 (estimate based on average service line cost)

- Pipe size: ¾-inch

- Service line length: 65 feet

- Pipe material costs per foot of pipe: Copper (Type K): $4.4 | HDPE: $0.50 | PEX: $0.70

- Inflation rate: 3%

The life cycle cost and total cost of ownership of the material options are compared in two ways.

First, in Table 1a, inflation is neglected, and all anticipated costs and returns (in the case of the copper’s scrap value at the end of life) are calculated as their present value in year zero to determine the life cycle cost.

For the plastics, the material and installation costs for replacement are taken as the same amount as the initial cost, minus $5,000 for installation, plus the material cost. This is calculated back to the present value to show the initial investment based on the 3% inflation rate to cover those costs in year 25 and year 50.

In the same manner, the value of the copper as scrap in year 75 is taken as 80% of the current cost of copper ($2.10 per pound) times the weight of the copper, brought back to the present value. This is a common engineering economics method for assessing the life cycle costs of various options (ref. ASTM E915).

The same comparison is made in Table 1b, but the inflation rate estimates the anticipated costs and returns across the range of options or the total cost of ownership. This total reflects the amount spent over the lifetime of the service for each material.

Consider long-term economic benefits

Table 1 shows that copper provides nearly $3,300 in savings per service line in constant dollars (present value) and nearly $32,000 in savings over the lifetime of the service in current dollars spent.

Even if the cost of both plastic materials is zero, copper is still more cost-effective. In fact, copper would have to increase 12.5 times before plastic became equally attractive on a life-cycle cost basis.

Even at that point, copper continues to offer a clear cost advantage in total dollars spent over the life of the service line. Decisions made on purchasing and installing underground water infrastructure today bare out in service for decades into the future. The decision made today can change over time with service calls and maintenance to dig up streets and lawns, shut off water service, and disrupt customers’ lives.

Best practices for lead service line replacement

U.S. Environmental Protection Agency recently initiated a public comment period, seeking feedback on the Lead and Copper Rule Improvements. The Copper Development Association advocates replacing LSLs with copper and that only full removal guarantees safety.

Cities and communities handle LSL replacement responsibilities differently. Some are doing the entire line (from the city water main through the private property), and others require owners to cover a certain portion of their private property financially. CDA stresses the importance of offering homeowners fully funded replacements and informing them of risks.

Point-of-use filters should be seen as interim measures until full replacement is feasible, and dielectric fittings are not recommended for long-term use due to durability concerns. Additionally, CDA highlights the need for comprehensive corrosion-control treatment in water systems, urging a multifaceted approach to water quality that goes beyond focusing solely on lead.

Installation

For proper copper service line installation, adhere to the following directives. Improper installation techniques can lead to failure or unnecessary repair:

1. Before attaching the flare nut, no material pipe-joint compound should be applied to the matting surface for a flare fitting and \ flared tube (See Figure 1).

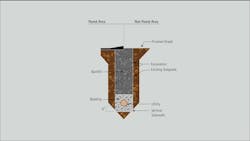

2. Put the copper piping in the “3 o’clock” position (also known as a gooseneck or pigtail) to ensure the backfill and soil packing process does not loosen the flare connection (See Figure 2).

3. The best option for installing copper underground is to bury it in direct contact with the soil or bedding. If wrapping is required, ensure proper sealing and protection are applied to eliminate any water or moisture from getting trapped between the wrap and copper service line.

4. Directional (trenchless) boring or pulling diameters are close to the outside diameter of the copper tube.

5. In open trenching/excavation, the copper service line should not lay directly on undisturbed or unexcavated soil at the bottom of the trench (See Figure 3).

6. Sleeving through foundations and walls must be sealed watertight (See Figure 4). Do not use caulks or spray insulation that contains ammonia or methanol. Sleeves can be sealed with Fernco™ electrometric clamps or an electrician’s duct seal.

About the Author

Marcus Elmer

Marcus Elmer, director of tube and fittings with the Copper Development Association, is a seasoned professional with over 15 years of experience in the plumbing and mechanical industries. He leverages his expertise to identify and influence market trends for copper tube and fittings products, driving strategic programs encompassing technical research, codes and standards, advocacy, and education. With a unique perspective gained from his time as a project manager with commercial plumbing, mechanical, and refrigeration contractors, Elmer has a deep understanding of the industry. He holds a Master of Business Administration from Union University in Tennessee and a Bachelor of Science in Construction from the University of Wisconsin-Stout.