Pumping System Upgrades Help Lower Energy Costs

By Steve Frasure, Carl McBride and John Tucker

Every industrialized nation struggles over issues of energy production and consumption. The United States is currently facing unprecedented issues ranging from state deregulation to limited power grid capital investment and government utility cost scrutiny. Wrestling with energy production and consumption will continue to be a part of our culture. While political, corporate and public entities disagree over ways to solve this quandary, all agree that it is critical to develop new ways to conserve energy.

Municipal systems are a modern marvel with thousands of miles of pipelines snaking through the ground to pump water into every home, school, hospital and building. These underground pipeline matrixes are one of the most advanced forms of water distribution in the world. But advanced as they may be, they are not immune to the effects of time.

Over the years, temperature, moisture and a myriad of elements wear down pipeline structure and create leaks, which in turn cause a loss of pressure within the system. In an effort to make up for that loss, municipalities often increase pressure within the system. This additional pressure stresses already existing cracks; the leaks then become larger, which perpetuates the problem. Not only is water wasted, but the amount of energy consumed to pump water in such situations rises exponentially with the pressure.

To compound the problem, energy costs have risen dramatically, particularly for oil-based fuels such as gasoline, diesel, kerosene and heating oil. This directly impacts the costs of maintaining a distribution system because of the enormous amount of electricity required for water distribution.

Pump ControlA major technological breakthrough has been accomplished to help solve the energy consumption challenges faced by every organization that pumps water. The philosophy behind the technology is similar to that of moving automobiles from inefficient carburetors to closely monitored and controlled electronic fuel injection systems.Dallas-based modular pump station manufacturer Flowtronex has developed a method of controlling pumps by tightly monitoring the system head curve of any particular distribution system to produce greater energy efficiency. When this new Automatic Power Saver technology (APS) is applied to pumping water into a specific distribution system, energy efficiency is significantly increased; leakage rates are significantly reduced; and distribution system aging is significantly slowed.

Over the span of about 18 months, the typical energy savings from APS technology will virtually pay for the new system. Those savings do not take into account the added benefit of less wasted water and wear on the system's components.

APS is contained strictly within the control system for a pump station, which serves as the heart of any pumping system. When properly adjusted for the system head curve of the distribution system to which it is applied, the technology will control the discharge pressure of the pumps. This forces the pumps to track the system head curve from zero flow to maximum rated flow of the pumping system.

Accuracy is ParamountThe APS system must have continuous feedback to properly accomplish its mission. It must also have pressure and flow data continuously updated through a flowmeter and a local pressure transducer. One or more remote pressure transducers can be included as well.The more accurate the information being supplied by these devices, the more accurately APS can track the system head curve. A well-designed, integrated pumping system must incorporate accurate and reliable pressure transducers and magnetic flowmeters, such as those offered by Rosemount and Krohne.

To control the pumps so that they are actually pumping on the system head curve, APS uses ABB variable frequency drives (VFDs). Each VFD continually feeds back its speed, so the controller can monitor operation of the pumping system and adjust the pump speed as necessary.

Figure 1 is an example of a single pump system using a 3x4x8 end suction centrifugal pump, operating at two pole speeds (3600 rpm maximum) using a 30 hp motor. Full speed (60 Hz) duty point is 450 gpm at 162 feet total dynamic head (TDH). After pumping system internal losses are deducted, discharge pressure is 150 feet, or 65 psi at full speed. Variable speed curves have been generated for each 2 Hz increment from 60 Hz to 40 Hz, and are shown. Of course, the constant speed curve is the 60 Hz curve. Ordinary VFD control is shown as the constant pressure curve, the line at 162 feet from zero flow to full flow. System head curve is shown as the curve from 132 feet to duty point, and beyond.

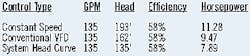

It is also important to review the horsepower requirements of the pump for each type of control, constant speed (60 Hz), constant pressure (conventional VFD) and system head curve. On each type of control, the flow rate of 135 gpm lies to the left of the 58 percent efficiency line, indicating that the actual efficiency is less than 58 percent. Since 58 percent is the minimum efficiency rating available for this pump, it is not possible to interpolate between 58 percent and a lower efficiency to determine what the actual efficiency is. For the sake of example, this article will use 58 percent as the efficiency for each control type in the comparison below.

Return on InvestmentIt is obvious that the horsepower reduction (conservation of energy) between constant speed and conventional VFD operations is 1.81 hp. That equates to approximately a 16% reduction in energy consumption. Horsepower reduction between constant speed and system head curve operations is 3.39 hp, which is about a 30 percent reduction in expensive energy consumption.APS is not a new, unproven theory. It was recently put to the test in the field under rugged conditions in the American desert Southwest.

No Field of DreamsA group of farmers banded together in Ogden, UT, to create the South Ogden Conservation District over a century ago, creating one of the nation's oldest water conservation districts. Since then, rapid urbanization has included approximately 500 new water connections each year over the past five years.In 2000, Odgen city officials found that when APS technology is applied to pumping water into a specific distribution system, water and energy costs can be significantly reduced. Since that time, three Flowtronex modular pumping systems have been installed at the district. One system replaced an outdated stick-built pump station while the other two added new capacity. The new stations are now pumping water from canals to residential areas with greater efficiency and enhanced energy conservation.

ConclusionThe supply of energy is not limitless and new ways to conserve resources must be employed. A new conservation philosophy requires better tools and innovative methods. New technology, such as APS, has been developed to fulfill that mission and allow municipalities to conserve precious energy resources while also meeting new budget goals.APS technology, which can be adapted to virtually any municipal water distribution system, not only saves time and costly maintenance repairs, but also allows municipal water systems to operate with greater energy efficiency. WW/

About the Authors; Steve Frasure, Flowtronex National Sales Manager, has two decades of experience in the area of municipal water works. Carl McBride is an Electrical Engineer for Flowtronex PSI and has been involved with control and instrumentation design for over 20 years. John Tucker, Water Systems Technical Coordinator, has been in the pumps and pumping industry for over 37 years.