Project Improves Efficiency, Reduces Expenses at Aging Water System

Buffalo Center is a community of about 1,500 people in northern Iowa. The town’s water and wastewater needs are served by a system that includes a water plant with two well heads, chemical feed, filtration and two high service pumps; one elevated tank; and two wastewater lift stations.

The town had installed a control system in the mid-1980s that provided basic on/off pump control with limited communications via a dedicated phone line to the elevated tank. However, Kelly Sabin, the town’s water supervisor, was struggling to maintain his aging control system.

Failures were becoming more common as the system aged and servicing the system had become virtually impossible. The system’s manufacturer had gone out of business so factory support and replacement parts were no longer available. Additionally, there were no electrical contractors willing to provide service to an old, poorly documented and maintained system.

“Over the years, there had been a lot of changes and ‘fixes’ made to the system. In the end, we had such a mess of wires that nobody wanted to touch it,” Sabin said.

System Upgrade

Allied Systems Inc. of Des Moines called on the town of Buffalo Center and suggested that Healy-Ruff could help.

“We had an old system that we couldn’t get parts for and nobody was willing to service. Healy-Ruff was not afraid to dig into a problem nobody else wanted to touch,” Sabin said.

Because of Healy-Ruff’s experience in water and wastewater applications, the company’s staff looked at the system differently than a typical electrical contractor or system integrator. The “spaghetti bowl” of wires didn’t intimidate them, because they understood the fundamentals of the process being controlled. After a brief tour of the town and facilities, Healy-Ruff and Allied Systems staff were able to sketch the solution on a notepad.

The project called for removal of most of the old control hardware and a complete rewiring of the panels. However, much of the existing infrastructure was re-used, including enclosures, motor starters, etc.

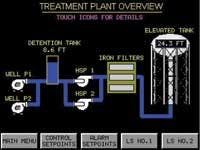

A Healy-Ruff Master V-PAC was installed in the plant providing control of the wells, chemical feed equipment, high service pumps, supervisory control and monitoring of the entire system. A Micro V-PAC was installed as an RTU to provide local control and operator interface at the elevated tank.

Once the plant/tank control was installed, it was decided to add Micro V-PAC RTUs at the two existing wastewater lift stations as well. The entire system communicates via spread spectrum radios, eliminating a dedicated telephone line and adding communications with the lift stations.

The move to a modern, reliable system has eliminated several major failures and process upsets per year. It has also freed up staff time.

“I used to spend 2-3 hours a week just babysitting and adjusting the system to keep it running. I now use that time to do other things,” Sabin said.

The system overview and touch-screen interface and control are also appreciated.

“Because Healy-Ruff knew our process, they knew how to lay out the touch screens and flow of information in a way that makes sense to the operator,” Sabin said. “They explained what everything did and how it worked. They really made us feel comfortable with the system.”

There were benefits beyond the basic system reliability and use. For example, the chemical feed at the well head used to turn on automatically with the pumps. The new system provides more accurate dosing and control. Another benefit is automatic alternation of the wells.

“Before, I would have to force alternation of the wells by going out to the tank once a month and manually change the lead/lag settings. And to be honest, there may have been a month or two I didn’t get to that,” Sabin said. “By automatically alternating the pumps, we will put much less stress on them and extend the life of the pumps. Not to mention the time it saves me.”

Staff also has greater control over the high service pumps feeding the tower.

“Both high service pumps used to run together all the time - about four hours a day. Now, we can not only alternate, but lead/lag as needed. In addition to the reduced wear and tear, there are huge energy savings. Now we can fill the tank in about four hours a day, but only need to run one pump to do so,” Sabin said. “We’ve cut our energy use in half.”

Another monthly utility bill saving came with the elimination of a dedicated phone line. By using spread spectrum radios, the installation team not only linked the plant and the tower, but they added monitoring and alarm notification for both of the lift stations in town.