Thermal Hydrolysis System Helps Increase Biogas Production

By Michele Kline, Nicholas Gurieff, and Jacob Bruus

Challenged with the goal of converting wastewater treatment systems from energy consumers to energy producers inevitably leads to an evaluation of the potential of biosolids. Biosolids are the largest energy resource available within a wastewater treatment plant. Therefore the use of biosolids needs to be optimized to take full advantage of its renewable energy properties.

Enhancement of biogas yields are generally achieved from the application of a pre-treatment process. One of the most effective of these is thermal hydrolysis. However, thermal hydrolysis generally consumes more energy than it helps produce. However, the process can be significantly improved if the solids fraction in the incoming biosolids is increased.

The thermal hydrolysis process uses heat to break down cell structure and organic material, resulting in a biosolids that is more soluble and readily biodegradable. In addition, the greater biodegradability of hydrolyzed sludge increases biogas yield and reduces the quantity of sludge for final disposal

Thermal hydrolysis has traditionally been performed within a batch system. Although proven and effective, the batch mode has involved high capital and operational costs, restricting the applications to only very large wastewater treatment facilities. Kruger's Exelys™ process was developed to overcome the challenges of thermal hydrolysis and build upon the efficiencies of the process.

Exelys is a continuous process that handles biosolids with a dry solids (DS) content greater than 20% w/w. The high solids content leads to a considerable savings of steam required to reach hydrolysis conditions, while the continuous operation allows for optimal energy recovery. Relative to traditional batch thermal hydrolysis, the system provides the same process conditions and hydrolysis product, but in a much more energy efficient manner.

Process Flow

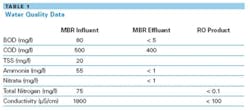

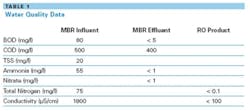

The Exelys process is shown in Figure 1. Dewatered biosolids from a storage silo or hopper is continuously fed to the process via a progressive cavity pump. As the biosolids enter the system, steam is continuously added to the system through a series of injection nozzles. As the mixture moves up the steam condenser section, the steam condenses transferring heat to the biosolids and raising the temperature to a required level for thermal hydrolysis to occur.

The heated biosolids pass through a self-cleaning static mixer which ensures that the heat is distributed evenly resulting in a homogenous biosolids/water mixture. The static mixer will also catch any steam that has not yet condensed. This ensures that all of the energy available from the steam injected is utilized effectively, maximizing the energy efficiency of the process.

After the biosolids are at the required temperature and pressure for thermal hydrolysis, the biosolids enter the reactor and flow at a low velocity resulting in plug flow. This plug flow ensures there is no short-circuiting and all the biosolids are under thermal hydrolysis conditions for the required amount of time.

After the reactor, the biosolids enter a heat exchanger system where they cool to a suitable temperature for the downstream mesophilic or thermophilic digestion process without requiring supplemental heating in the digesters. The heat exchangers are a tube-in-tube design which allows for easy cleaning and maintenance. The cooling water from the heat exchanger system can be used for pre-heating boiler water, building heat or for other low temperature heat sources at the plant.

After the heat exchanger system, there are provisions to inject treated wastewater into the biosolids. The water injection can be used to dilute and cool the biosolids as required by the downstream digestion process.

The final component of the system is the pressure holding pump. This pump is controlled to maintain a pressure set point in the system. In most cases the pressure holding pump can also be used to feed the downstream digestion process.

Further Optimization

Exelys can be used in a number of process configurations. Normally, it would precede digestion. However, it can be incorporated into a patented process configuration to further improve energy efficiency - Exelys™-DLD (Digestion-Lysis-Digestion) system.

Energy consumption is decreased because there are less biosolids for hydrolysis after the first digestion step. By digesting the hydrolyzed biosolids again, biogas yields from the raw biosolids are even greater than if a conventional LD (Lysis-Digestion) system was used. Because the Exelys unit is smaller, its energy requirements can generally be covered by waste heat recovered from electricity production from the biogas.

Demonstration Facility

Since October 2010, an Exelys-DLD process has been in continuous full-scale operation at the Hillerød wastewater treatment plant in Denmark. Before installation of the system, the plant used a thermophilic anaerobic digestion process with a retention time of 25 days and a DS reduction rate of 35-40%. With the Exelys-DLD configuration installed, the treatment plant operator has recorded an estimated increase of 30% in biogas production (which is sold to the local heating network), improved dewatering and a reduction of an estimated 25% in biosolids to be disposed. The Hillerød WWTP is continuing to operate the process for further evaluation and optimization of the system performance.

WW

About the Authors: Michele Kline is a Senior Product Manager for Biosolids and Bioenergy Systems at I. Kruger Inc. located in Cary, NC. She has over 7 years experience within the water and wastewater industry. Dr. Nicholas Gurieff is the product manager for Exelys™ continuous sludge thermal hydrolysis solution with Veolia Water Solutions & Technologies - Krüger A/S, Denmark. Dr. Jacob H. Bruus is the Vice Director in Krüger's International Division with a primary responsibility for Solutions.

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles