Motor Control Modernization Improves Pump Performance

By Paul Blaiklock

Construction of the new wastewater networks and treatment plant for the City of Montreal was started in 1974 and completed in 1998. Eight of the 17 large pumps in the plant are driven by wound rotor induction motors (WRIM) of 3,050 and 5,150 horsepower, and were controlled by vintage variable speed controls for which parts and service were an issue. Modern slip power recovery systems using low voltage variable frequency drives were chosen to replace the older controls and give improved performance.

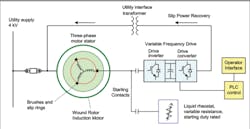

A WRIM is a machine with a 3-phase wound stator that is usually connected directly to the power system. The rotor also has a 3-phase winding, usually connected in a wye (or star) circuit. The three terminals of the rotor winding are connected to separate slip rings, which are normally connected to a variable resistance such as a liquid rheostat or resistor bank, used for starting the motor. The speed of the motor can be changed by changing the rotor resistance, which changes the slip, rotor current, torque, and the speed.

In previous systems the power in the resistor was lost as heat. Later, speed control of wound rotor motors employed slip power recovery (SPR) controls for cost and energy efficiency reasons. These older implementations of SPR technology saved energy, but had disadvantages of low power factor operation and creating torque pulsations.

The use of state-of-the-art low voltage pulse-width modulated converters eliminates these disadvantages while retaining all the energy savings. This new implementation builds on standard variable frequency motor drives used in industry, with hardware which is very reliable and well supported, and is appropriate for new or existing motors.

New Controls

The drive inverter is connected to the rotor through brushes. The variable resistance rheostat is used for starting, then it is disconnected and the drive connected to take control. The drive takes power off the rotor, and the more power that is taken out, the lower the motor speed. In the drive, the inverter creates DC current, which is fed to the converter where low voltage 60 Hz power is generated. A transformer increases the 465 volt slip power to 4 kV so that it can be fed back into the main supply.

When the regenerated power from the rotor is a minimum, the motor is running at rated speed. The drive system gives the user the option to short the slip rings and run the motor like an induction motor without the SPR drive.

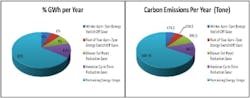

The energy savings relative to using only the rheostat depend on the motor speed. For example, a calculation for a 5,000 hp wound rotor motor running continually on only a rheostat at 90% speed, compared to the SPR system, showed slip power savings of $60,000 per year if the electricity costs $0.08 per kWh.

In the slip power equipment cabinet, the operator control screen is on the right hand door, the inverters and converter are in the central three cabinets, and the left hand cabinets hold the contactors. The liquid rheostat is separated and mounted behind.

To simplify installation, the panels were designed the same size as, and a direct replacement for, the original panels. The existing main stator breaker was retained. Motor controls were installed one motor at a time with no impact on plant operations.

Advantages

The new equipment provides a number of advantages:

- Eliminates spare parts problems with the old control equipment, and provides new and very reliable standard drive equipment.

- Instead of losing power in the rheostat, it is recovered and returned to the supply through a transformer, thus saving money.

- Provides unity power factor and low harmonics at the utility, and much lower torque pulsations than the original SPR equipment.

- Provides the capability to operate the motors over a wide speed range, in some cases above synchronous speed if power is fed back into the rotor.

- For an existing WRIM, the equipment is potentially less expensive than a full size medium voltage stator drive for starting and varying the motor speed, with a higher efficiency and possibly a smaller footprint.

- Relative to a full size stator fed drive, the SPR equipment provides redundancy so that if the drive has a fault, the rheostat can start, run, and vary the motor speed.

In the Montreal plant, the water flow for pumping can vary from an average of 23 to 30 cubic meters/second up to 84 cubic meters/second on rainy days. Before employing the new controls, the plant used between three and nine synchronous pumps to pump most of the flow, and two variable speed pumps to equalize the level in the wells. Since the new drives were installed, four to five variable speed pumps are on line, and the synchronous pumps are run to take the excess flow. This change has been made primarily because the new drives give better level control and are more efficient.

WW

About the Author: Paul Blaiklock is Marketing Manager for TMEIC GE in Roanoke, VA. TMEIC GE is a joint venture between Toshiba, Mitsubishi Electric, and General Electric in the industrial drive systems business.

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles