How Parallel Pumps can be Pushed into Damaging Low Flow Pump Internal "Suction Recirculation"

By Allan R. Budris

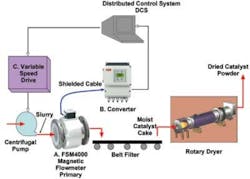

This writer was recently called to investigate a vibration (and cavitation damage) problem with several vertical wet-pit lift sewage pumps, that occurred near minimum speed. The investigation revealed that this problem was not caused by a structural or hydraulic resonance (which was initially suspected), but instead was actually caused by a combination of several of the hydraulic issues that have been covered in a number of past (separate) "Pump Tips" columns. Given that this was not the first time that the writer has encountered this hydraulic compounding, I thought it was worth exploring this situation with my readers.

The separate issues involved were:

1. High Suction Energy & Insufficient NPSH Margin(October 2007 Column)

2. Variable speed operation(March 2008 Column)

3. Impellers having little or no vane overlap (October 2008 Column)

4. Parallel pump operation(November 2008 Column)

5. Damage from Low Flow Pump Internal "Suction Recirculation" (June 2010).

Hydraulic Issues combined

Separately, the above hydraulic issues would not have been a problem, however, the combination resulted in vibration levels of over 1.0 inches/sec measured at the top of the motor, and cavitation damage to the epoxy coated, cast iron impeller. Basically what happened was that the pump design created high suction energy (even at reduced speeds) due to the lack of impeller vane overlap (because of only having two vanes for solids handling) and a large impeller eye. This was then compounded by parallel and variable speed operation which pushed the individual pumps into their low flow, suction recirculation, regions (which was above 50% of bep, due to the high pump specific speed). Finally, there was not enough NPSH margin to get beyond the damaging cavitation region, especially given the fact that the pumps were in suction recirculation.

High Suction Energy / No Impeller Vane Overlap

The suction energy for these end suction pumps calculated to be 139 x 106, based on the below formula:

Suction Energy (S.E.) = De x N x S x S.G.

Where: De = Impeller eye diameter (inches)

N = Pump speed (rpm)

S = Suction specific speed (rpm x (gpm)0.5) / (NPSHR)0.75)

S.G. = Specific gravity of liquid pumped

This value of suction energy would not have been at the "High Suction Energy" level, had the end suction impeller vanes had at least 15o of overlap, where the gating value is 160 x 106, as shown in Table 1. But these two vane sewage pump impellers did not meet this requirement, which meant that the gating value was actually 100 x 106.

This put the pumps into the High Suction Energy range. Pumps with high suction energy and low NPSH margins, especially when operated in the suction recirculation flow range, may experience noise, vibration and/or minor cavitation erosion damage with impeller materials that have low cavitation resistance, such as cast iron.

Variable Speed Operation

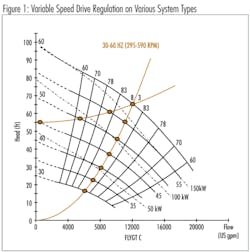

The biggest reliability issue for High Suction Energy pumps is to avoid operation in the suction recirculation region. However, variable speed operation can actually move the relative pump flow rate (as a percent of the bep), towards the start of suction recirculation. When operated on systems with a significant static pressure component (as shown in Figure 1), the relative flow rate actually decreases as the pump speed is reduced, which not only reduces the pump efficiency, but also moves it closer to the start of suction recirculation. Therefore, the greater the speed turn down in such a system, the lower the percent bep flow rate.

Parallel Pump Operation

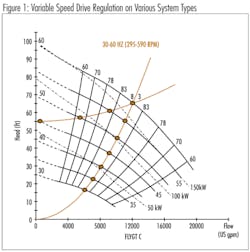

Besides the reduction in pump percent bep flow rate from speed reduction, parallel operation of two or more identical pumps will reduce the percent bep flow rate even further, as shown in Figure 2. In this actual field, high suction energy, sewage lift pump application, reducing the pump speed from 60 Hz (1185 rpm) to 40 Hz (790 rpm), reduces the bep flow rate from 97% to 80%. This, by its self, would not be a reliability issue, at least with sufficient NPSH margin, and/or a cavitation resistant impeller (stainless steel or hard coated). However, when the pump was then operated in parallel with another identical pump, the bep flow rates were pushed back even further, to 54% and 46%, depending on the speed.

For this application, it would be best that these pumps not be operated in parallel, unless the system flow requirement exceeds the one pump maximum flow rate of about 8,000 gpm (and then for short periods of time), both from an efficiency and reliability stand point.

Suction Recirculation

Now, according to Figure 3, the start of suction recirculation for these high suction energy sewage lift pumps, which have a specific speed approaching 5,000, and suction specific speed approximately 8,500, is around 52%. This means that these high suction energy pumps will be operating in (or close to) suction recirculation, whenever they are operated in parallel.

The actual impact of this reduced bep flow can be seen in Figure 4. At higher bep flow rates (above the start of suction recirculation) the suction pressure pulsations increase as the speed (and percent bep flow rate) increase, due to higher suction energy at the higher speeds. However, once the pump is pushed back closer to the start of suction recirculation, the suction pressure pulsations (and vibration) greatly increase, peaking around the start of suction recirculation (52% of bep), even though the speed and suction energy both decrease as the percent bep flow rate decreases.

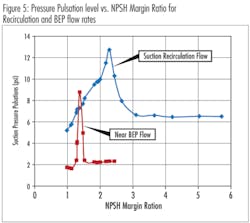

NPSH Margin Impact

Figure 5 shows just how much more damaging suction recirculation can be compared to classic cavitation, and the impact of the NPSH Margin Ratio on this cavitation damage (as determined by the suction pressure pulsation level). Tests of this (not the field sewage pump) "High Suction Energy" pump at its best efficiency and start of suction recirculation flow rates demonstrate not only a much higher suction pressure pulsations peak (from cavitation) for the suction recirculation flow rate (in the maximum erosion flow region), but the width of the suction recirculation pulsation peak is much broader than the peak near the bep flow rate, and it occurs at a higher NPSH margin ratio. It can take a NPSH margin ratio (NPSHA/NPSHR) of over 3.0 to get beyond the suction recirculation peak, and even at that the suction pressure pulsation level is 75% that of the bep flow peak. In the actual sewage lift pump field application, it took NPSH Margin Ratios of at least 6.0 in suction recirculation to substantially reduce the cavitation caused suction pressure pulsation level.

Conclusions

The above actual field problem demonstrates why it is essential that special care be taken when operating "High Suction Energy" pumps in parallel, from both a reliability and efficiency standpoint. It is normally best to operate the minimum number of pumps necessary for the various system requirements.

WW

References:

1. Allan R. Budris & Heinz P. Bloch, "Pump User's Handbook – Life Extension", Third Edition, 2010.

2. Allan R. Budris & Philip A. Mayleben, "The Effects of NPSH Margin, Suction Energy and Air on Centrifugal Pump Reliability", (1998 Texas A&M Pump Users Symposium).

About the Author: Allan R. Budris, P.E., is an independent consulting engineer who specializes in training, failure analysis, troubleshooting, reliability, efficiency audits and litigation support on pumps and pumping systems. With offices in Washington, NJ, he can be contacted via e-mail at [email protected].

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles