Energy Efficient Digesters Help Off-Set Power Cost Increases

By Phil Brandenburg

The Du Quoin, IL, Water Reclamation Plant recently experienced an 85% increase in its power rates and began evaluating the energy efficiency of every piece of equipment in its facility.

Fortunately, the plant operates in a very energy efficient manner. In 2006, the city built and started-up a new Water Reclamation Plant, replacing a 40-year-old two-phased trickling filter facility. The process configuration of the new plant consists of two counter-current aeration reactors, two rapid removal helical scraper clarifiers, and two counter-current aeration digesters, all supplied by Schreiber, and a belt filter press made by Komline-Sanderson.

The city has now had roughly two years of operating experience and has been pleased with the quality of the effluent produced. As a result of the low fecal counts in the water leaving the facility, the city has been granted a disinfection exemption from the state of Illinois. Another bright spot has been the reduced energy demands of the new plant.

The facility is currently receiving a little over half of the original design load and consuming about 20% less power than originally projected for this level of loading. Consequently, as the plant reaches design conditions the system will save the City of Du Quoin approximately $30,000 per year in power bills.

When it comes to energy efficiency, the Schreiber digesters are performing well. The city operates two 200,000 gallon digesters and the mixing for each of these units is supplied by only one 2 hp motor for each basin. Staff had become increasingly curious about how much of the plant’s energy efficiency could be attributed to these “energy-miser” digesters. Unfortunately, the plant has only one power meter for the entire facility, therefore measuring the power consumed only by the digesters was not possible without considerable expenditures for power sub-metering.

However, after giving the matter some thought, staff decided that they might be able to get a handle on the digesters’ energy usage by employing a “comparative facility” approach to the issue.

Chester, IL, is located near Du Quoin and operates a wastewater treatment facility that is an ideal candidate for a comparative study. The wastewater treatment facility at Chester is very similar in equipment type and size. In fact, the equipment components installed in the two plants are identical – except for their digesters – which are of a different type and brand. The Du Quoin and Chester digesters also experience similar solids loading characteristics. The Chester plant digesters usually experience solids of around 4%, while Du Quoin typically maintains a solids content of about 4.5%. Also, both plants experience occasional excursions of up to a maximum of 6% solids.

Although the Chester plant is rated as a 3 mgd plant and Du Quoin was designed for a 2.4 mgd load, the two plants are each handling a current average load of around 1.5 mgd. (Chester at 1.6 and Du Quoin at 1.4).

When the power usage numbers for the two plants were compared over a 12-month period, it was found that the Chester plant consumed, on a monthly basis, roughly 102,000 KWH per mgd of influent compare with Du Quoin’s 51,000 KWH per mgd per month. The resulting difference in the average monthly power usage should be attributable to the difference in digesters, since the two plants are otherwise very comparable.

The Chester digesters use three 80 hp blowers for a total of 240 hp for mixing and aeration. Since one of the three blowers is always in “standby mode” the operating horsepower is limited to 160 hp (i.e. one 80 hp blower for each basin) which consumes about 65,000 KWH on a monthly basis or about 0.09 KWH per gallon per month.

In contrast, the Du Quoin digesters employ separate means for mixing and aeration components. They have a 2 hp motor on each digester used exclusively for mixing. These small motors run 24/7 to insure adequate mixing and consume about 2,200 KWH per month for mixing.

For digester aeration, the facility has three-30 hp blowers (one for each basin and one in reserve). However, since mixing is accomplished via the 2 hp motors, staff only need to run the large aeration blowers intermittently to maintain the target DO levels of 0.5 to 1.5 mg/L in the digesters. The blowers only operate when the DO drops below the target level, so they typically are only “on” for an accumulated total of 12 hours per 24 hour period which consumes an average of roughly 16,300 KWH per month. Together, digester mixing and aeration power consumption is roughly 18,500 KWH per month or about 0.05 KWH per gallon per month.

Based on this comparative facility approach, the Schreiber digesters at Du Quoin require 44% less power than the power consumed by the digesters at the neighboring facility. The 46,500 KWH difference in monthly power used by the digesters accounts for approximately 91% of the difference in the monthly power usage between the two plants.

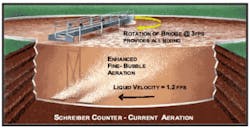

Each of the Du Quoin circular basin digesters uses a Schreiber aeration bridge that spans the distance from the structural center pier to the outer wall. A “turntable” type bearing mounted on the center pier provides support and allows the bridge to rotate around the basin. On the outer wall, the bridge is supported and propelled by a single 2 hp peripheral traction drive carriage that continuously moves the bridge around the top of the outer wall at a perimeter speed of about 3 ft/second. “Lift-out” type fine-bubble aeration diffuser assemblies are suspended from the bridge such that the diffusers are positioned about 9" above the floor of the basin.

These high oxygen transfer diffuser assemblies are moved through the water in the basin by the bridge as it rotates about the basin. This movement through the liquid creates a horizontal circular flow pattern in the basin, which is sufficient to keep the solids well mixed and in suspension – independent of aeration. This independence of aeration and mixing has proven to be the important energy saving advantage for the digesters. When aeration is not needed in the basin, the relatively energy-hungry 30 hp aeration blowers can be turned off. The mixing is then accomplished via the 2 hp peripheral drive motor.

This method of operation minimizes the energy used for mixing and offers a full 100% turndown range of airflows together with a high degree of oxygen transfer efficiency.

An interesting side note is that the two Schreiber digesters were originally two clarifiers that served the old trickling filter plant. They were converted into digesters when the city built the new plant in 2006, which saved a considerable amount in construction costs. WW

About the Author:

Phil Brandenburg is the superintendent of the water reclamation plant for the City of Du Quoin, IL.