Next Generation Wastewater Surface Aeration

Surface aeration should be viewed not as a discrete piece of equipment, but as a system that requires analysis of the tank geometry, say Roger Gyger and Prakash Balan. Here they look at how high efficiency surface aerators can provide significant energy savings compared to traditional pitched blade aerators. Includes case studies of Saudi Arabia and Brazil.

Akey requirement of any aerobic wastewater treatment system is to provide adequate dissolved oxygen to the biological process. A related system requirement is to provide sufficient mixing, which insures a fairly homogenous mixture within the activated sludge aeration basins. Since the introduction of the activated sludge process a wide variety of systems have been used to provide oxygen dissolution and bulk mixing. These include various types of diffusers, injectors and mechanical devices, such as surface aerators.

Most of these aeration systems were originally developed over thirty years ago when the cost of electric energy was significantly lower than it is today. In some cases, the original technology has been refined to reflect a greater emphasis on energy efficiency. A frequently cited example of this technology evolution is the current use of fine bubble diffuser in place of the original coarse bubble diffuser systems. However, an equally significant series of developments has occurred with surface aeration technology.

During the 1970s low speed surface aerators became one of the primary aeration and mixing systems, which were used in the activated sludge process. This technology largely incorporated pitched blade turbine (PBT) surface impellers, which operated at nominal speeds of 30 to 60 rpm.

There were a number of suppliers of surface aeration systems and several thousand units were eventually supplied worldwide, in a wide variety of wastewater treatment applications. These applications included municipal and industrial wastewaters, using either air or high purity oxygen as the aeration gas. Since the introduction and broad commercialisation of the original PBT surface aerator technology, a number of different impeller configurations have been offered in an attempt to improve the oxygen transfer efficiency of the system. Generally speaking, these modifications did little to significantly increase the standard aeration efficiency (SAE) of the equipment, because these modified systems were still based on the original, incomplete oxygen transfer approach.

However, developments in surface aeration technology over the last number of years have validated a new, improved approach to oxygen transfer, which has subsequently been incorporated into a series of commercial, high efficiency surface aerator designs.

Fundamentals of surface aeration systems

All aeration systems transfer (dissolve) oxygen from the gas phase (e.g. air), into the liquid phase (e.g. activated sludge), by creating interfacial surface area across which the oxygen transfer can occur. In a diffusion system, the interfacial area is created by a large number of bubbles.

By comparison, in a surface aeration system, the interfacial area is created through two distinct mechanisms. The first mechanism is oxygen transfer in the "Spray Zone", or the area created by the liquid "umbrella" of the surface aerator. The second oxygen transfer mechanism occurs in the "Re-Aeration Zone". These two oxygen transfer zones are shown in Figure 1.

In traditional surface aerator technology, it was long held that the preponderance of the oxygen transfer occurred in the "Spray Zone". Based on this belief, surface aerators were designed to maximise the performance of the Spray Zone. This approach resulted in a large, vertically-oriented aerator umbrella with PBT surface aerators.

Typical standard aeration efficiencies (SAEs) for these types of devices were in the range of 2.9 to 3.2 pounds of oxygen per horsepower-hour.

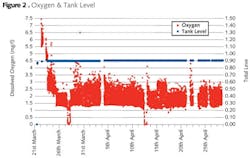

The evaluation of surface aerators began to change in the mid 1990s as alternative mass transfer models were developed [1]. The relative importance of the "Spray Zone" and the "Re-Aeration Zone" were rigorously analysed and it became apparent that the bulk of the oxygen transfer (dissolution), was actually occurring in the "Re-Aeration Zone". It further became apparent that the performance of the "Re-Aeration Zone" is enhanced by fluid volume and higher pumping rates through the surface aerator. Under these circumstances, the mass transfer performance of a surface aerator could be maximised by treating the aerator primarily as a "pump", instead of a spray creator. The affect of the current two-zone, high efficiency approach is shown very graphically in Figure 2, where the operation of a conventional surface aerator is contrasted with the operation of the HI-FLO Surface Aerator® in the same basin.

Applying the concepts associated with the two-zone mass transfer model has resulted in current surface aerator SAEs in the range of 3.5 to 4.1 pounds of oxygen per horsepower-hour. These efficiencies represent a substantial improvement from the traditional surface aerator performance and have enabled the new high efficiency surface aerator systems to compete quite well with any alternative oxygen transfer devices [2 & 3].

Facility considerations - process design

The historical approach to surface aeration system design centered around the selection of a singular piece of equipment. However, the current view of surface aeration system design uses a more holistic approach, which recognises the effects of the unique installation characteristics and related process performance criteria. Surface aeration should be viewed not as a discrete piece of equipment, but as a system, which requires analysis of the tank geometry (e.g. depth to width ratio), projected aerator operating speeds and plant loading conditions.

There are several approaches for implementing a rigorous process design approach, including test tank and field testing, along with the use of state-of-the-art modeling tools, such as computational fluid analysis (CFD). Although CFD has been in commercial use for quite some time, only within the last number of years has it been applied broadly to wastewater aeration and mixing applications. Simulations can provide a very vivid and revealing profile of the anticipated profile for the combination of an aerator and a tank.

Mechanical design

A complete understanding of the fundamentals of surface aeration, along with a rigorous analysis of the process design requirements facilitates the development of an efficient and robust surface aerator mechanical design. This design begins with the "wetted parts", primarily the impeller.

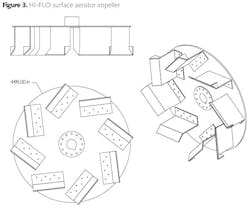

A diagram of a typical HI-FLO impeller is shown in Figure 3. These impellers were specifically developed and designed to maximise the energy efficiency of the two -zone mass transfer conditions described earlier. These impellers have been manufactured from a variety of ferrous materials including coated carbon steel and various types of stainless steel. The two other major components of the surface aeration system are the geardrive and motor.

Typical aerator speeds for the HI-FLO system range from approximately 40 to 70 rpm, which is provided as the design output speed of the geardrive. In some cases the aerators can be designed to operate at variable speeds to accommodate lower oxygen demand conditions and/or "mixing only" operation (e.g. for aerobic/anoxic basins).

In these cases, the aerators are provided with variable frequency drives, which can be tied into the overall activated sludge control system. The use of VFD's provides additional energy savings and another level of operating flexibility. The current selection of geardrives, motors and VFS's have proven to be extremely reliable in wastewater treatment aeration applications.

International surface aerator applications

Over the past eight years more than 200 HI-FLO Surface Aerators have been installed in a wide variety of wastewater treatment applications. These include both municipal and industrial applications for air and high purity oxygen activated sludge systems.

Although this technology was originally developed in North America and the bulk of the installations have been in that area, recently the technology has been receiving interest from other areas. Two relatively recent applications are indicative of the interest and applicability of the HI-FLO Surface Aeration system for international installations.

The first international application of the HI-FLO Surface Aerators was at the KLABIN Otacilio Costa pulp and paper plant in Brazil. A total of six, 150 HP HI-FLO units were installed in this facility in 2008.

The total volume of the aeration basins is 13,500m3. The influent flow is approximately 1000 m3/hour, with a BOD concentration of 450 mg/l.

The most recent international application for the HI-FLO technology was at the Aramco NTSP Plant in Dhahran, Saudi Arabia.This system was installed during 2009 and surface aerators were installed in five existing air activated sludge aeration basins, as a replacement for an older generation surface aeration system. In addition, two new aeration basins were constructed.

Each of the basins consisted of three bays. A total of 21 HI-FLO surface aerators were installed, with 50 HP units in the first bays, 40 HP units in the second bays and 20 HP units in the third bays. Energy savings was the primary objective of the aeration system project and the system was selected over several other options, including fine bubble diffusers.

Conclusions

• The current generation of high efficiency surface aerators can provide significant energy savings compared to traditional PBT (pitched blade turbine) aerators and in many cases can provide oxygen transfer efficiencies equal to or better than fine bubble diffusers systems

• High efficiency surface aerators have been installed in a wide variety of municipal and industrial wastewater applications under different environmental conditions and mechanical constraints

• A significant number of witnessed ASCE Clean Water Oxygen Transfer Tests have been conducted to validate the process performance of the high efficiency surface aerators

• Overall design of the high efficiency aerator package maximizes the value of advancements in component designs for geardrives, motors and variable frequency drives

• In view of the energy efficiency and durability of the current generation of surface aerators they should be considered as a viable alternative for all activated sludge aeration applications.

References

1. "Oxygen Mass Transfer Fundamentals of Surface Aerators"; John R. McWhirter, Jia-Ming Chern & Joseph C. Hutter; Industrial Engineering Chemical Research, Vol 34, No.8

2. "Clean Water Testing of Innovative Surface Aerators Promises Significant Savings for Chattanooga's Moccasin Bend WWTP"; Gary M.Cosby, P.E. & Daniel W. Gay: WEFTEC 2003 Proceedings

3. Energy Savings and Settleability Control for Bellingham's HPO Process"; Randal Samstag, James Hagstrom, B. Narayanan, Larry Bateman & Geoff Smyth; PNCA 2007 Annual Meeting Proceedings

4. "Wastewater Treatment Plant Energy Reduction with High Efficiency Aerators"; Rabea Manakhah, David Evans & Roger Gyger; Proceedings of Saudi Water 2011

Author's note:Roger F. Gyger & Prakash Balan, Ph.D. are from Mixing & Mass Transfer Technologies LLC.

For more information on the discussed system, please contact: [email protected]. For more information on aeration and Waterworld, Industrial Waterworld and Water & Wastewater International coverage on the subject, please scan this QR code:

More Water & WasteWater International Current Issue Articles

More Water & WasteWater International Archives Issue Articles