Crime Stopper: Water Meters and Magnets

Editor’s note: This article first appeared in the May 2010 edition of Water Efficiency.

How do you protect your meter network from losing its measuring capability? One option to improve and protect measure devices like dry-dial water meters is to use passive magnetic field indicators to detect the action of a strong magnetic field primarily coming from neodymium magnets. These indicators are especially useful for water meters already in use in networks (external installation), but in the case of new water meters, the passive magnetic field indicators can, by design, be installed also inside the device. The indicators are also used to detect a strong magnetic field action on other vulnerable measuring devices, like watt-hour meters and gas meters.

Introduction

The uses of neodymium magnets or a magnetic field, created also by electromagnetic devices, can have a negative influence on the correct functioning of measuring devices through reversible or irreversible changes of their measuring characteristics. For example, many electromechanical induction and electronic watt-hour meters lower their indications of electric energy consumption, and low-voltage current transformers decrease the currents in their secondary windings (Hazardous influence of rare-earth magnets on low-voltage current transformer as the evidence of EMC compatibility lack 2006). Dry dial water meters and many gas meters completely lose their capability of measuring the medium used in spite of its flow. The described situations are evidence of the lack of electromagnetic compatibility of measuring devices (Directions of protection of watt-hour meters from influence of external magnetic fields 2005).

- To install on internal surface of transparent casing of measuring device

- To install on external casing surface of measuring device

Information about influencing the measuring characteristics of devices to reduce their indications is becoming more easily accessible from many sources: articles (Source: www.ednasia.com/print.asp?articleId=23996), Internet Web sites, and discussion forums (Slowing down electric meter 2008). Additionally, the great accessibility of neodymium magnets and the continuous decrease in their prices (because of cheap mass-production in China) has had an influence on the propagation of the phenomenon of illegal media consumption with the use of these magnets. This phenomenon is well known in Asia and Europe, and also appears in the US (“To Catch a Thief).

Basic Information About Rare—Earth Magnets

Development of the group of magnets based on rare-earth elements dates from the 1980s, when the Japanese Sumitomo Company obtained patent protection of the metallic compounds of ferromagnetic cobalt (Co), samarium (Sm), and also ferromagnetic iron (Fe) and neodymium (Nd) with boron (B) (Source: www.sei.co.jp ).

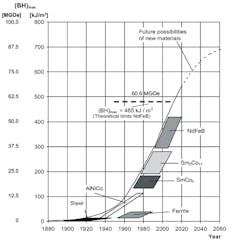

Considering the fact that samarium and neodymium belong to elements, which very rarely occur in nature, they are called rare-earth elements, and magnets with these elements are named rare-earth magnets. Magnets of the NdFeB type are characterized by extremely high-energy density values: 37.7–50.3 MGOe (300–400 kJ/m3) (Figure 1).

Dry Dial Water Meters

The most widespread construction of water meters is the dry dial meter. It is characterized by the separation of the counter gear and counter from flowing water, which forces the turbine to work. A magnetic clutch is used to transfer the drive from the turbine placed in the “wet” chamber of the meter to the counter, placed in the “dry” chamber.

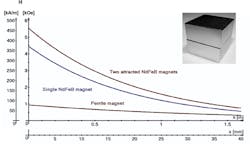

For instance, according to the European standard EN 14154 (Water meters–Part 3: Test methods and equipment 2005) in force, water meters should be resistant to an external magnetic field with a field strength up to 1.26 kOe (100 kA/m). A ferrite magnet with the energy of 6.28 MGOe (50 kJ/m3) creates such a value (Figure 2).

However, water meters meeting the requirement of the standard are not resistant to the action of neodymium magnets, which create magnetic field strengths over four times greater than ferrite magnets (Figure 2) [Directions of protection of watt-hour meters from influence of external magnetic fields 2005]. A neodymium magnet influences the magnetic clutch of the dry dial water meter, causing a complete stop of its measurement despite flowing water (Figure 3).

However, after removing the magnet from the dry dial water meter, its indication returns to its correct measuring class. The interference process is fully reversible-–the magnet does not damage the water meter.

Construction Changes in Measuring Devices

The problem of the magnetic non-resistance of many measuring devices, including dry dial water meters, has forced on their producers construction changes in these devices, e.g., replacement of elements with non-ferromagnetic ones, increasing the distance between the problematic subassemblies and the casings of the measuring devices, as well as internal or external magnetic screens. All these activities are connected with eliminating the negative influence of a strong magnetic field or its limitation. In fact, all these activities, like magnetic shielding, raise the threshold of magnetic resistance of measuring devices, but they will never be completely resistant to a stronger magnetic field, e.g., created by attracted neodymium magnets (Figure 2).

Moreover, all these changes can be done only at the design and production stage, but the problem concerns, first of all, many millions of already-installed measuring devices in networks. In this case, there is no possibility to change the design of those devices.

In the case of already-installed measuring devices, the simple solution seems to be not to eliminate the negative influence of strong magnetic fields, but their permanent detection. Nowadays there are some devices, which can detect if a neodymium magnet was used. They work on the basis of the Hall effect, magnetoresistance effect, or change the domain structure of magnetic material (European Community Design No. 000485487 2006).

Measurement of Residual Magnetism

The influence of magnets on dry dial water meters can lead to the magnetization of some of their parts, like: circlips, magnetic screens (when materials are wrongly chosen), and other ferromagnetic construction members. To detect the magnetization of ferromagnetic elements in a measuring device by a neodymium magnet, electronic meters applying Hall sensors or magnetoresistors are often used (Hall effect magnetic field meter of SMS-102 type 2003).

- To install on internal surface of transparent casing of measuring device

- To install on external casing surface of measuring device

Methods used for the magnetization state measurement (residual magnetism) cannot be treated as court evidence because of technical circumstances: They do not give reliable information on the source of the magnetic field that was used (if the magnetic field influenced the correct measurement made by the meter), and, first of all, the “history” of measuring devices is not known in most cases, i.e., if their parts could have been under the influence of magnetization before the installation of the dry dial water meters in networks. Most objects made of ferritic steel in our surroundings are characterized by residual magnetism, which can be detected by using electronic measuring devices with Hall sensors or magnetoresistors even though nobody put a neodymium magnet to these objects. For example, scissors, after some time, can attract paperclips. Residual magnetism is also formed in many steel elements because of mechanical stress, e.g., in production processes. That is why many meters, even during the time of delivery, can be magnetized. Detected magnetization can also be caused by using a weak ferrite magnet, to which dry dial water meters should be resistant (according to the EN 14154 standard [Water meters–Part 3: Test methods and equipment 2005]).

Even if a method of residual magnetism measurement can definitely show that a neodymium magnet was used, there is an easy way to remove residual magnetism from ferritic steel elements by using an alternating, decaying magnetic field, which can be created by a rotating magnet used to stop measuring process of dry dial water meters.

a) Before magnetic field action—multi-domain structure visible in form of geometric figures

b) After magnetic field action with strength over 3.52 kOe (280 kA/m); single-domain structure—lack of geometric figures

(Source: European Community Design No. 000485487 2006; www.magneto.pl/en/page/136)

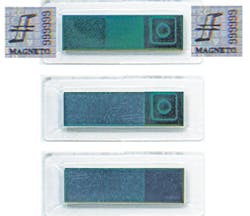

Passive Magnetic Field Indicators

A passive magnetic field indicator uses a magnetic domain pattern method. By affecting measuring devices with a strong magnetic field, it is possible to observe changes in the domain pattern of the magnetic field indicator (Figure 4) [Addressing an EMC weakness due to strong static magnetic fields 2007]. One can obtain the domain structure of the indicator through magnetization in a multi-pole circuit. This structure is visible by using a special magnetic film reader, which polarizes in a magnetic field according to Bitter patterns (Hubert, A., and R. Schaefer 1998).

The indicator, having a hermetic, transparent casing, is in the form of a sticker, which can be easily installed on measuring devices. When a magnetic field of the appropriate strength of about 3.52 kOe (280 kA/m)—e.g., coming from a neodymium magnet (Figure 2)—affects the indicator, then the multi-domain structures (geometric figures) of the indicator are re-magnetized—the light green contours of the magnetic geometric figures become irreversibly blurred or the figures disappear completely (Figure 4b).

In the case of measuring devices, which additionally need the detection of a lower magnetic field strength, one can use the two-threshold magnetic field indicator (Figure 5).

a) Before magnetic field action

b) After magnetic field action with strength over 0.1 kOe (8 kA/m)

c) After magnetic field action with strength over 3.52 kOe (280 kA/m)

(Source: www.magneto.pl/en/page/136)

The magnetic field indicator is divided into three fields: a dark green reference field, a light green field, and a field with a magnetic geometric figure (a triangle, circle, or square with a circle inside each figure) with a light green contour on a dark green background. When a magnetic field of a strength over 0.1 kOe (8 kA/m) (e.g., coming from a neodymium magnet placed at a distance of a dozen or so centimeters from the indicator, or a ferrite magnet placed at a distance of a few centimeters from the indicator) has acted on the indicator, the light green field irreversibly changes its color into dark green, equal to the color of the reference field (Figure 5b). When a magnetic field of a strength of about 3.52 kOe (280 kA/m) (e.g., coming from a neodymium magnet placed at a distance of a few millimeters from the indicator) has acted on the indicator, the light green contours of the magnetic geometric figure become irreversibly blurred, or the figure disappears completely (Figure 5c).

The two-threshold magnetic field indicator MFI-4 can be used in devices, which, because of their design, would need a few MFI-3 indicators or in devices, which are also sensitive to magnetic fields from weaker magnets, e.g., ferrite or AlNiCo magnets.

The magnetic field indicators MFI-3 and MFI-4 have been designed in two versions:

- To install on internal surface of transparent casing of measuring device

- To install on external casing surface of measuring device

The latter version of indicators MFI-3 and MFI-4 requires additional mechanical protection in the form of holograms, with logo, name, serial number, code, etc., applied on one or both the indicator side wings (Figure 4a and 5a). The holograms are characterized by so-called self-destruction (each attempt of removal from the surface they are applied to causes their destruction that indicates mechanical tampering).

Other Media Measuring Devices Under Influence of Neodymium Magnets

A strong magnetic field also negatively influences the correct operation of other measuring devices than dry dial water meters. Watt-hour meters and gas meters belong to these devices.

There are two types of watt-hours meters: induction and electronic. Induction watt-hour meters have found such applications as residential meters and electronic watt-hour meters are especially applicable as commercial meters, but it is considered that electronic metering solutions can also provide the residential energy market with the accuracy, flexibility, and networking benefits currently unavailable in most locations.

The most susceptible elements in induction watt-hour meters to NdFeB magnets are the magnetic circuits of current and voltage coils and the braking magnets of aluminum rotor disks (EMC Defect in watt-hour meter [Ferraris] operating in strong stationary magnetic field 2006). By putting a neodymium magnet near the measuring coils of a meter, the meter reading is lower than the real electric energy consumption; it means that the measuring error becomes negative. However, after removing the magnet from the meter, its indication returns to its correct measuring class. In this case, the interference process is reversible.

Editor's note: This article first appeared in the May 2010 edition of Water Efficiency. How do you protect your meter network from losing its measuring capability? One option to improve and protect measure devices like dry-dial water meters is to use passive magnetic field indicators to detect the action of a strong magnetic field primarily coming from neodymium magnets. These indicators are especially useful for water meters already in use in networks (external installation), but in the case of new water meters, the passive magnetic field indicators can, by design, be installed also inside the device. The indicators are also used to detect a strong magnetic field action on other vulnerable measuring devices, like watt-hour meters and gas meters. Introduction The uses of neodymium magnets or a magnetic field, created also by electromagnetic devices, can have a negative influence on the correct functioning of measuring devices through reversible or irreversible changes of their measuring characteristics. For example, many electromechanical induction and electronic watt-hour meters lower their indications of electric energy consumption, and low-voltage current transformers decrease the currents in their secondary windings (Hazardous influence of rare-earth magnets on low-voltage current transformer as the evidence of EMC compatibility lack 2006). Dry dial water meters and many gas meters completely lose their capability of measuring the medium used in spite of its flow. The described situations are evidence of the lack of electromagnetic compatibility of measuring devices (Directions of protection of watt-hour meters from influence of external magnetic fields 2005). [text_ad] Information about influencing the measuring characteristics of devices to reduce their indications is becoming more easily accessible from many sources: articles (Source: www.ednasia.com/print.asp?articleId=23996), Internet Web sites, and discussion forums (Slowing down electric meter 2008). Additionally, the great accessibility of neodymium magnets and the continuous decrease in their prices (because of cheap mass-production in China) has had an influence on the propagation of the phenomenon of illegal media consumption with the use of these magnets. This phenomenon is well known in Asia and Europe, and also appears in the US ("To Catch a Thief). Basic Information About Rare—Earth Magnets Development of the group of magnets based on rare-earth elements dates from the 1980s, when the Japanese Sumitomo Company obtained patent protection of the metallic compounds of ferromagnetic cobalt (Co), samarium (Sm), and also ferromagnetic iron (Fe) and neodymium (Nd) with boron (B) (Source: www.sei.co.jp ). Considering the fact that samarium and neodymium belong to elements, which very rarely occur in nature, they are called rare-earth elements, and magnets with these elements are named rare-earth magnets. Magnets of the NdFeB type are characterized by extremely high-energy density values: 37.7–50.3 MGOe (300–400 kJ/m3) (Figure 1). [caption id="attachment_1304" align="alignnone" width="600"]- To install on internal surface of transparent casing of measuring device

- To install on external casing surface of measuring device

An attack with a strong external magnetic field on the braking magnet of the meter can lead to its demagnetization and, what follows, to irreversible changes of the measuring characteristic of the meter. As a consequence of these changes, the aluminum disk spins faster than it should, and the meter reading is higher than the real energy consumption.

The popularity of the electronic watt-hour meters is growing because of its numerous measuring-visualization functions. Many different kinds of electronic watt-hour meters are known, depending on measuring process applied. Even though the measuring process differs in various kinds of meters, it does not change the fact that meters are equipped with different common subassemblies, which are susceptible to a magnetic field, no matter which measuring process is used. It especially concerns electronic watt-hour meters using susceptible current transformers for current measurements. Their magnetic characteristics are linear in the whole range of their normal operation. However, the influence of a strong external magnetic field leads to a change of the current transformer magnetic characteristics. The idea is to saturate the core of the current transformer or distort the flux in the core with the use of a neodymium magnet (like in the case of induction watt-hour meters current and voltage coils). This procedure results in less billing because of lower electric energy consumption reading. The phenomenon is reversible—the meter indication returns to its normal measuring class after removing the magnet.

The above-mentioned additional common subassemblies of electronic watt-hour meters are mechanical counter stepper motors, transformers supplying electronic circuits, and electric rate switches. If these elements are under the influence of an external magnetic field, it can lead to a total cease of counting consumed electric energy.

For electronic watt-hour meters, the phenomenon of magnetic field action by using neodymium magnets is reversible and does not damage the meter. It makes it possible to corrupt electronic watt-hour meters, the detection of which is very difficult if passive magnetic field indicators are not used.

The problem of magnetic non-resistance also concerns bellows gas meters, used for residential and commercial gas consumption measuring. The internal construction consists of diaphragms—bellows, which are moved by flowing gas. Each cycle of their work, measuring the same volume of gas, is transferred by a crank mechanism to a gear and counter.

In the case of gas meters equipped with diaphragms, which parts are made of ferritic steel, not plastics or aluminum, putting a neodymium magnet against the gas meter disrupts a regular operation of its mechanism. This manifests itself by temporarily attracting and holding down the diaphragm by the magnet, and then—by a release of the diaphragm under flowing gas. This irregular operation of the gas meter leads to a limitation of gas flow and, in practice, manifests itself in a weak flame in such appliances as gas cookers, water heaters, gas ovens, etc., causing, even, an overestimating of the gas consumption reading. After putting the neodymium magnet against the gas meter, it can come to the situation when the flame goes out in operating gas appliances and, after a removal of the magnet, gas can begin to escape. (It is very dangerous.)

(Source: Water meters, www.bmeters.pl/woda_produkty_prezenter-wyposazenie.php?id=16)

However in many cases, depending on the placing of gas meter valves and diaphragms at the moment of putting the magnet, there is a possibility of non-throttled gas flow (not controlled by a counting mechanism) that is tantamount to gas theft.

Conclusions

The fastest method to improve the protection of measuring devices, including dry dial water meters, as well as other measuring devices, from a strong magnetic field is to use passive magnetic field indicators. This method is especially useful for devices already in use in networks.

Although many companies manufacturing measuring devices have taken many initiatives (e.g., presented in chapter 4), usually it turned out that the devices are not properly shielded to protect them from magnetic field influence, and then detection of an external magnetic field is needed, e.g., by using passive magnetic field indicators. An example of this solution is shown in Figure 6.

In the case of new measuring devices, the passive magnetic field indicator can, by design, be installed inside the device so that the indicator would be visible through a transparent wall of the device. It is only possible during the production process of devices to install the indicators inside e.g., water meters, but not after their installation in networks. The solution from Figure 6, with the external installation of the indicator, is the only one reasonable solution for many millions of measuring devices already measuring medium consumption in networks.

References

Addressing an EMC weakness due to strong static magnetic fields. 2007 IEEE International Symposium on Electromagnetic Compatibility, Honolulu, HI, July 8–13, 2007.

Brzozowski, Carol. To Catch a Thief. Water Efficiency, Vol. 3, No. 5, July/August 2008: www.waterefficiency.net/july-august-2008/catch-a-thief.aspx.

Conner, Margery. EDN Asia. Reed Business Information, Reed Elsevier Inc., 2010: www.ednasia.com/print.asp?articleId=23996.

EMC Defect in watt-hour meter (Ferraris) operating in strong stationary magnetic field, 18th International Wroclaw Symposium and Exhibition on Electromagnetic Compatibility EMC 2006, Wroclaw, Poland, June 28–30, 2006.

European Community Design No. 000485487, Magnetic field indicators, Office of Harmonization in the Internal Market (Trade Marks and Designs), Alicante, Spain, 2006.

European Standard EN 14154: Water meters–Part 3: Test methods and equipment, February 2005.

Hall effect magnetic field meter of SMS-102 type Operating manual, December 1, 2003.

Hazardous influence of rare-earth magnets on low-voltage current transformer as the evidence of EMC compatibility lack, 18th International Wroclaw Symposium and Exhibition on Electromagnetic Compatibility EMC 2006, Wroclaw, Poland, June 28–30, 2006.

Hubert, A. and Schaefer, R.: Magnetic domains. The Analysis of Magnetic Microstructures. Berlin, New York, Springer, 1998.

Rare-earth permanent magnets VACODYM, VACOMAX, Catalogue PD-002, Vacuumschmelze GmbH&Co. KG, 2007.

The Research and Development Office Magneto Ultd.: www.magneto.pl/en/page/136.

Seminar, Directions of protection of watt-hour meters from influence of external magnetic fields; Polish Chapter of IEEE Magnetics Society, Czestochowa, Poland, May 20, 2005.

Slowing down electric meter, March 14, 2008: http://system-review.blogspot.com/2008/03/slowing-down-electric-meter.html.

Sumitomo Electric Industries, LTD. www.sei.co.jp.

Water meters, Catalogue of B METERS POLSKA, page 34; www.bmeters.pl/woda_produkty_prezenter-wyposazenie.php?id=16.