Pumped Storage: Using Water Towers, Aquifer Well Pumps to Generate Energy During Peak Demand Periods

By Allan R. Budris

Last month's Pump Tips column provided many pump system efficiency improvement opportunities that could significantly reduce a municipality's electric utility bill by reducing the total electrical consumption. However, total electric consumption is only one portion of the utility electric bill. Peak demand charges (which are added to the consumption rate charge) can account for half of the utility electric bill in a municipal or industrial plant.

Demand is a charge based upon the maximum or peak rate of energy use during the billing period. In addition, there are typically multiple consumption rates based on the "time-of-use." This means that any electrical usage that can be shifted from "on-peak" periods to "off-peak" periods can further cut a facility's electric bill. In fact, some electrical utilities in Texas actually have a zero nighttime, off-peak rate for selected customers.

One way to reduce these demand and higher on-peak electric charges is to store excess power during off-peak periods and then tap into this stored energy during on-peak periods. Pumped storage has been found to be the most efficient means of storing the large amounts of energy required to have a measurable impact on a municipal or industrial electric bill. Such a pump energy storage system would consist of two reservoirs, each capable of storing large amounts of water at a significant elevation difference.

During off-peak (lower-demand) periods, low-cost electricity is used to pump water from the lower-elevation reservoir to the higher-elevation reservoir. Then, during times of peak demand, this extra stored water can be released from the higher-elevation reservoir and run through the pump (operating in reverse as a turbine) to generate electricity, which can be used to offset local usage. This not only reduces the amount of electricity that must be purchased from the utility during higher-rate periods but also reduces the maximum period demand charges.

Municipal pumped storage systems are not always feasible, however, because of the high initial capital costs and/or excessively long financial payback. This is especially true if reservoirs must be built and pumps/turbines and piping must be purchased and installed.

AQUIFER-BASED PUMPED STORAGE SYSTEM

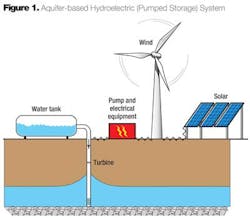

There is, however, a lower cost option that may be available to many municipalities for storing off-peak energy and recovering this energy during peak demand periods: an aquifer-pumped storage system (See Fig. 1). Many municipalities already have the basic infrastructure in place that could be (relatively easily) modified to store energy during low-peak demand periods and then generate hydroelectric power for the municipality during periods of peak demand.

It should be noted that an aquifer-based hydroelectric system can also be used in conjunction with solar or wind power generating systems to provide backup power for nights and periods of low wind when these renewable power sources are not producing electricity.

An aquifer pumped-storage system functions in a similar manner as a typical hydroelectric pumped-storage installation, except for the fact that the lower-elevation reservoir would be replaced by an underground aquifer, and the upper reservoir would be replaced by an existing water tower (or reservoir). In addition, the existing well pump, motor and piping could serve as the power recovery turbine and generator (see "Optimizing Efficiency When Pumps are Operated as Both Pumps and Power Recovery Turbines," WW, October 2010).

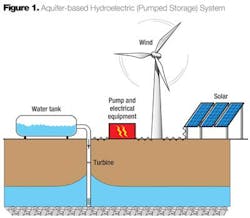

There are, however, issues that must be evaluated in order to determine the feasibility and benefits of an aquifer pumped storage system, especially given the fact that, under the best circumstances, the overall energy storage/recovery efficiency is only about 67 percent (less the motor/generator efficiency, and the negative impact of the aquifer water level mounding, governed by the ground permeability, and pipe friction losses). The key questions around feasibility issues include:

In addition to these fundamental issues, some (relatively low-cost) changes would be required in order to operate the pump system in reverse, as a hydroelectric turbine, on an existing water supply system, such as:

- 1. If the pump motor contains a "non-reverse ratchet," it must be removed to allow the motor to rotate in reverse as a generator.

- 2. If there are any check valves in the pump discharge piping, these valves must be bypassed during turbine operation.

- 3. If there is a check valve at the pump inlet (foot valve), it must be removed and, if it is deemed necessary, replaced with a compound valve that will act as both a normal check valve during pump operation and (based on a signal) a throttle valve during turbine operation.

- 4. If the power generated by the turbine is greater than the input power to the pump, the pump shafting should be checked to ensure that it is not overstressed. (If necessary, it should be replaced.)

- 5. If the pump construction includes a line shaft from the surface over about 100 feet long, the line-shaft bearings are open (lubricated by the fluid pumped), and a foot valve is being removed for turbine operation, then the line-shafting should be replaced by one with an enclosing tube that provides separate line bearing lubrication.

- 6. Providing the necessary electrical controls for turbine operation.

- 7. Ensuring that all necessary environmental regulations and permits are satisfied.

AQUIFER HYDROELECTRIC EXAMPLE

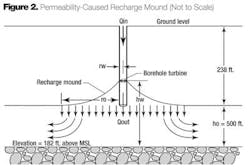

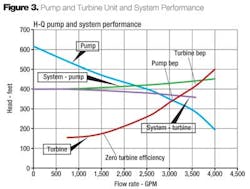

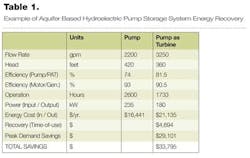

Table 1 gives an example (based on the single pump/turbine performance shown in Figure 3) of potential energy cost recovery, assuming a $0.025/kW off-peak electricity pumping charge rate and a $0.075/kW on-peak turbine (savings) charge rate, with moderate aquifer mounding. A peak-demand charge rate of $13.50/kW per month was used, given the fact that utility charge rates typically range from less than $2/kW to over $25/kW. The example illustrates that the aquifer hydroelectric pumped storage system's total electrical savings would be $33,795 per pump (basically by replacing maximum on-peak electrical usage with off-peak).

Relieving this peak power usage should be of significant value to both the water and electric utilities, and there may be ways for them to work together to achieve and share this potential savings.

CONCLUSIONS

While performing the necessary evaluation to determine the feasibility and benefits of installing an aquifer pumped storage system may seem tedious, the potential savings to a municipality's electric bill can be substantial with reasonable paybacks. And if you need assistance, there are organizations and companies available to help with this analysis.

About the Author: Allan R. Budris, P.E., is an independent consulting engineer who specializes in training, failure analysis, troubleshooting, reliability, efficiency audits, and litigation support on pumps and pumping systems. He can be contacted via email at [email protected].

REFERENCES

1. Aquifer Based Hydroelectric Systems (ABHS), "Preliminary Design of an Aquifer Pumped Storage System," (study conducted by Stevens Institute of Technology, Hoboken, NJ, May 4, 2008).

2. Steven G. Liescheidt, P.E., CSI-CCS, "Energy Management for Motor-Driven Systems," (online course No. E-8001, http://www.PDHengineer.com).