A Cost-Efficient Option for Stormwater Treatment

By Greg Land and Bengt Hansen

Chemically Enhanced Primary Treatment (CEPT) is a simple and cost-effective option for stormwater treatment, but it is often overlooked. Unlike many other alternatives, CEPT does not require the construction of a new facility; an existing facility can be employed with only a minimal equipment investment.

CEPT is a process solution used in primary settling tanks to improve removal of impurities. Coagulants (e.g., ferric, alumina, or polyaluminum salts) and flocculant (e.g., polymer) are added to the water before entering the settling tanks. The coagulant agglomerates the smaller (non-settling) solids. Some of the dissolved substances, such as sulfides and phosphorus, precipitate with the floc particles. The flocculant binds the coagulated particles with a long chain polymer to form strong and rapid-settling flocs. This chemistry can be manipulated to create floc of variable strength and settling rates.

Depending on the application, the CEPT process can be applied where medium settling, medium strength floc is required, or for stormwater treatment where rapidly settling, high strength floc is required.

Stormwater CEPT

During storm flow conditions, primary effluent BOD and suspended solids (SS) increase, and a portion of the flow can be bypassed around the activated sludge (AS). Otherwise the AS may be washed out, resulting in diminished treatment until biomass is recovered. The following scenario illustrates how CEPT can improve stormwater treatment.

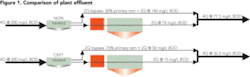

Consider a treatment plant designed for the flow Q. Suppose that the flow during a stormwater event is four times the designed one (4Q). At double flow (2Q) the primary and secondary treated effluent BOD is 15 mg/L. Above 2Q the primary treated water is bypassed around the secondary.

Assume a 200 mg/L influent BOD at 4Q receives primary treatment. 2Q of the primary effluent is routed through the secondary and 2Q is bypassed around. If the non-treated primary process removes 30% BOD and the CEPT removes 75% BOD, then the combined plant effluent will be 77.5 mg/L BOD and 32.5 mg/L BOD respectively (see Fig. 1). CEPT can reduce the environmental impact during a stormwater event by more than 50%.

To achieve good results with CEPT, it is important to evaluate what coagulant (or coagulants) to use, select the right polymer, and find an optimal dosing point and appropriate dosing techniques for the different products.

Full-Scale Field Application

King County, Brown and Caldwell, and Kemira participated in one of the first hybrid CEPT applications designed to treat stormwater flows in the Seattle, WA, South WWTP. This full-scale trial aimed to document treatment capacity at surface overflow rates (SOR) exceeding 3,600 gpd/sf during storm events.

Although the CEPT process has been applied worldwide, there was limited data available that documented treatment success at the higher SOR rates with a true stormwater quality influent. The goal was to determine whether a modified CEPT process was capable of producing the rapid precipitation and floc strength required for settling under these conditions.

Using existing equipment circumvents the need to build additional treatment capacity for these events. In this case, a 38 MGD plant could reduce investment costs by as much as $4.1 million (Kruegel et al., Melcer et al.).

The focus was placed on chemical selection, distribution equipment mechanics, and chemical dosing locations to develop the best process approach for the field trial.

Using a newly developed jar test method for high SOR applications, a series of coagulant combinations and flocculants were evaluated to select the dose chemistry. A coagulant dose of 60 mg/L FeCl3 supplemented by 12 mg/L PAX-XL19 and a flocculant dose of 0.3–0.5 mg/L anionic polymer were selected. These doses were selected for the specific waste stream application and reflect a high range limit.

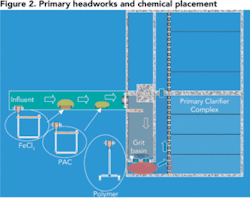

Next, atomizing mist dosing devices were constructed and situated at optimal addition points ahead of the primary clarifier influent. The coagulants were injected into the highly mixed aerated channel ahead of the grit basin, and the ferric was applied about 15 seconds ahead of the PAX-XL19. The polymer dosage point was critical and was selected after careful testing. The selected site produced such strong, rapidly settling particles that the floc dropped 4 feet in depth in the initial 30-foot clarifier run, and the water above the floc blanket was extremely clear. Figure 2 illustrates the primary headworks and the

chemical placement.

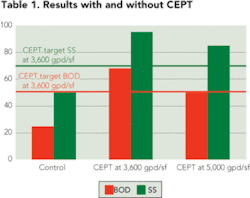

Using this project format, it was possible to demonstrate that the storm CEPT hybrid was capable of exceeding the removal targets of 50% BOD removal and 70% SS removal at SOR values of 5,000 gpd/sf, compared with 25% and 50%, respectively, for the control at 3,6000 gpd/sf (see Table 1).

Conclusion

When one considers the investment for a few storage tanks, dosing equipment and piping for coagulants and polymers against the cost of plant expansion required with many other stormwater technologies, CEPT proves to be an economical and effective stormwater treatment methodology.

References

- Krugel S., et al. (2005) High rate chemically enhanced primary treatment as a tool for wet weather plant optimization and re-rating. Proc. 78th WEFTEC Conference – CDROM, Water Environment Federation, Arlington, VA.

- Melcer, J., et al. (2005) Alternative operational strategies to control pollyants in peak wet weather flows. Proc. 78th WEFTEC Conference – CDROM, Water Environment Federation, Arlington, VA.

About the Authors:

- Greg Land has 35 years of experience in the water and wastewater field. He served as the plant operations supervisor for the city of Omaha’s WWTP prior to assuming the Kemiron technical sales position for the Pacific Northwest region of the US. He is currently projects development manager with Kemira Water, focused on CEPT and filament control strategies within the U.S.

- Bengt Hansen is a product manager for customer solutions at Kemira Water. He has 18 years of experience in the water, wastewater and sludge treatment field. He holds a masters of science in chemical engineering from the University of Lund, Sweden, and has published several international articles and presentations.