Back to Basics: How to Improve Vertical Turbine Pump Reliability through Optimum Bearing Selection

By Allan Budris

Vertical turbine pumps (VTPs) offer many unique advantages for many applications. For instance, the vertical construction takes up little floor space; priming problems can be avoided due to submersion of the impellers in liquid; the first stage impeller can be lowered (by increasing the pit depth, if necessary) to provide the desired NPSH margin; multistage construction and midrange specific speeds offer high efficiencies; and modular construction allows the pumps to be customized for many applications.

VTPs are available in deep well, wet pit (short setting or close-coupled), canned, and submersible motor configurations. Accordingly, my September 2008 column on the advantages and cautions of using VTPs on water and wastewater applications concentrated primarily on cavitation, vibration and axial thrust, as well as how to avoid the associated field problems.

An additional key issue that should be considered when applying a VTP on liquids that contain solids, abrasives and/or air is the selection of the bearing material and/or construction, given the fact that the bearings are immersed in and lubricated by the fluid pumped during most typical applications. As such, they are also generally the first component to deteriorate in a VTP.

Conventional Vertical Turbine Pump Bearings

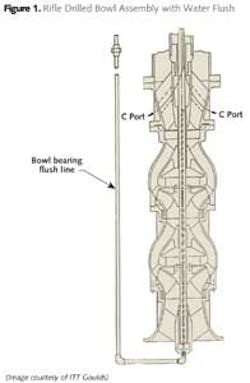

VTP bearings are found in the bowl assembly (in each bowl, suction case/bell and possibly the discharge case) and in the column assembly (unless the pump has a short setting or is driven by a submersible motor located below the bowl assembly). Bowl bearings are normally made of a low-lead bronze material, set against a 416 stainless steel bowl shaft without any replaceable sleeves (see Fig. 1).

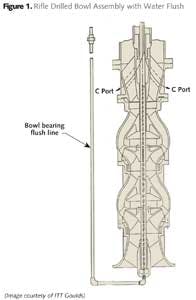

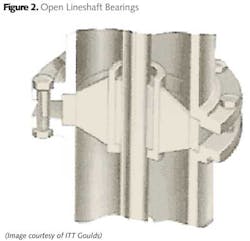

Further, the column assembly connects the bowl assembly to the aboveground discharge head. Typical column bearings are either constructed of a cutless rubber (see Fig. 2), operating against a stainless steel shaft sleeve (lubricated by the fluid pumped) or bronze enclosed in a tube (lubricated by either an oil drip or water flush, introduced at the discharge head, and exiting into the well or sump at the top of the bowl assembly; see Fig. 3).

Open Lineshaft

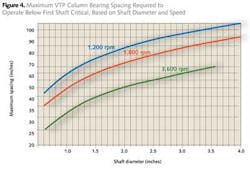

Open column line shaft bearing construction is recommended for ease of maintenance and/or whenever a special bearing material is required; it is not recommended for longer settings greater than about 100 feet. Renewable shaft sleeves or hard facing on the shaft are available for longer life, and typical bearing spacing is 10 feet for well applications. However, for shorter settings, the shaft size and spacing should be selected so that the shafting will operate below its first critical speed (see Fig. 4). For example, at 1,800 RPM, the maximum bearing spacing for a 1 11/16 inch (1.69 inch) shaft would be five feet.

Enclosed Column

In this configuration, an enclosing tube provides the lineshaft with protection from the pumped liquid and ensures clean lubrication to the bearings prior to startup, which is especially important for deeper settings (over about 100 feet). The lineshaft bearings are typically spaced at five-foot intervals to support the lineshaft. An internal spiral groove allows the lubricant to flow between the shaft and the inner face of the bearing, while the outside of the bearing is threaded to connect the enclosing tube sections.

This construction minimizes maintenance of the column bearings in abrasive services. The oil (or water) lubrication for the enclosed construction is introduced at the surface. A tank attached to the discharge head provides oil through a solenoid valve to the tension bearing in the stuffing box. It then flows by gravity into the enclosing tube and through the bypass port in the bowl assembly discharge case. Alternate lubricants such as clean water or grease can also be used with enclosed lineshaft construction. Lubricating oils are available that are acceptable for discharge into the pumped liquid, even when it is intended for drinking water.

Bowl Assembly Bearings

Line shaft bearings can be protected from abrasive wear by either constructing them of cutless rubber (which can tolerate fairly high levels of suspended solids) or by the use of an enclosed tube around the lineshaft; bowl bearings, however, must operate in the pumped liquid. This means that, in most cases, the choice of bearing material (see Table 1) is normally the only option that will allow the pump to handle higher levels of solids or air/vapor. Air can enter a VTP when the well or sump levels are low (vortexing), can be entrained in the pumpage due to mixing, or can be released from entrainment due cavitation in the first and/or second stage of the pump (as discussed in the September 2008 column). Once in the bowl assembly, the air and vapors (being lighter then water) can be centrifuged into the bearings. Some VTP manufacturers do, however, offer rifle-drilled bowl assembly shafts with an external water flush that can greatly improve the bowl bearing life when handling solids/abrasives and/or air/vapor, as shown in Figure 1.

Bearing Material Options

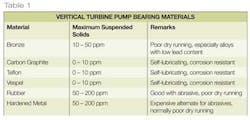

Table 1 lists the classes of column and bowl assembly bearing materials generally available for VTPs, with each manufacturer typically offering their own specific alloys. The bronze alloys typically offered have very low (if any) lead due to environmental concerns, which reduces their dry-running ability. Carbon graphite bearings probably offer one of the most efficient dry-running capabilities but have very low solids/abrasive tolerance; they are also available with a variety of fillers. Teflon bearings also have excellent dry-running capability and poor abrasive tolerance, plus they are available with a variety of fillers. However, Teflon bearings cannot be retained with a press fit due to the potential of cold flow.

Vespel bearings are also much like Teflon bearings but with improved dimensional stability, and they are also available with a variety of fillers, including Teflon and carbon. Rubber bearings are primarily used for open lineshaft column applications and are very proficient at handling solids, as long as they are not too sharp. However, they have poor lubricity and should be wetted prior to startup, which could pose a problem with deep settings (over about 100 feet), especially if the pump does not have a foot (check) valve and it takes too long for the pumped liquid to reach the upper bearings. Rubber bearings are seldom used for bowl bearings due to the larger required running clearance. Finally, hardened surface metal bearings are also available, such as chromium oxide and tungsten carbide, for abrasive/solid applications, but they are expensive and also have poor lubricity for handling air and/or vapors.

About the Author: Allan R. Budris, P.E., is an independent consulting engineer who specializes in training, failure analysis, troubleshooting, reliability, efficiency audits, and litigation support on pumps and pumping systems. With offices in Washington, N.J., he can be contacted via email at [email protected].