Troubleshoot Pump Problems Like a 'Best-in-Class' Pump User

By Allan R. Budris

When a pump fails or is in distress, pump users normally have two basic choices: disassemble the pump, replace any obviously damaged pump components in kind, and return the pump to service or have a knowledgeable person troubleshoot the situation, identify the root cause and permanently fix the basic problem. The latter has the potential to greatly reduce life cycle costs and is characteristic of a best-in-class pump user.

During the four decades I worked for major pump manufacturers - plus an additional decade of pump consulting - I’ve been able to successfully troubleshoot many field pump problems. This experience has led to the following methodology for resolving pump field problems. Identifying the reason for concern is the first step, followed by data collection, analysis, determining the root cause, and finally, establishing, selecting and completing the corrective actions.

Reason for Concern

A pump problem may present itself in a number of ways, including failure of a critical pump component, high vibration/noise, and/or loss of pump performance.

- Failure or excessive wear of a critical pump component typically involves a bearing, mechanical seal, shaft, impeller or casing. If this represents a short Mean Time Between Failure, it should be of special concern.

- Excessive vibration is a good indicator that some damaging phenomenon could be occurring within a pump or the immediate pump system, which is why many pump users monitor pump vibration on a regular basis.

- Failure of a pump to meet the expected performance, whether it is low head, low flow rate, or high input power draw, could be a pump and/or system issue.

Data Collection

Once the basic problem has been identified, the next step is to collect all relevant measurements and data, fully documenting the events leading up to the reported pump problem or failure. Consider the following questions:

Was the pump operating at very high or low flow rates?

Was the pump operating in parallel or series with another pump?

What were the system settings just prior to the event?

Was there excessive force from the suction and/or discharge piping?

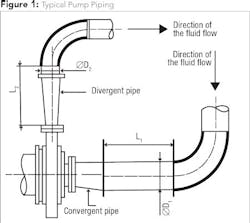

Are there sufficient straight inlet pipe lengths (see Figure 1)?

Is the pump shaft misaligned with the motor?

Was the bearing lubricating oil level correct?

Is the oil contaminated with water or other impurities?

The pump should next be disassembled and the parts inspected for wear, damage and/or discoloration. Operating clearances (such as the wear rings) should be measured. Collect pump performance curves, the system performance curve, vibration and alignment history, actual performance history, and lubrication data.

Identify and collect historical data on identical pumps in the same system, and/or pumps with similar problems. What are the differences between the failed pump and the identical pump(s) in this or similar systems?

If there are any questions on the actual field pump or system performance, conduct a field test with calibrated instruments (see WW, Jan. 2009).

Analysis

Once the appropriate data has been collected, some preliminary analyses should be conducted, such as determining the Suction Energy and NPSH Margin, operating percent flow and time spent at each flow rate, and peak vibration amplitudes and their frequencies. Determine if the pump was operating in its “suction recirculation” low flow region for any length of time. Finally, any wear should be evaluated to determine if it was caused by cavitation, abrasion, corrosion and/or metal contact.

Root Cause

In order to determine the true root cause, you must continue to ask the question “What caused this?” until you reach the final root cause. Root causes generally fall into one of the following categories:

- Wrong pump selection: This could include the wrong pump type (see WW, Feb. 2012), size, impeller diameter or speed, which could cause the pump to operate far from its best efficiency point (BEP).

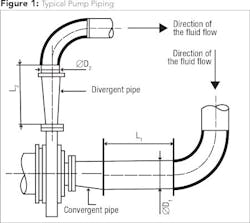

- Excessive vibration: This can have a mechanical cause, such as a structural residence, unbalanced rotor, misaligned coupling, or excessive nozzle loads (see WW, Apr. 2013), or can be caused by a hydraulic issue (see Table 1).

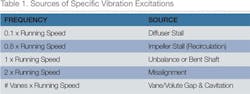

- Pump operation, especially in parallel setups, can push a pump to operate far from the pump BEP (see WW, March 2011), particularly if the pump is pushed into Suction Recirculation (see Figure 2) and it is a High Suction Energy pump. This can cause high vibration at the vane pass frequency and cavitation damage on the pressure side of the impeller vanes.

- Insufficient NPSH Margin (see WW, Dec. 2012 and Jan. 2013): If the pump has high suction energy and an insufficient NPSH margin, cavitation in the pump can cause pitting (erosion) damage to the impeller (see WW, Dec. 2015), vane pass vibration, noise and possible loss of pump head and flow. This situation can be further exacerbated by poor (short) suction piping (see Figure 3, and WW, Apr. 2009, Oct. 2013), or poor sump design (WW, June 2015). Abrasives and corrosives will accelerate cavitation damage (see WW, Mar. 2014, Dec. 2014).

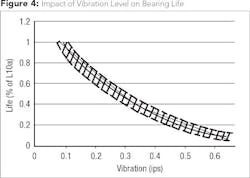

- Bearing life can be shortened by pump vibration (see Figure 4), bad coupling/motor alignment, operation away from the BEP, and/or poor bearing lubrication (see WW, Aug. 2010, Sept. 2013).

- Water hammer shocks (see WW, Apr. 2014) from quick valve closures and excessive piping nozzle loads can cause structural failures of the casing.

Corrective Actions

Once the root cause of a pump failure has been determined, there is normally more than one corrective action that can be taken to resolve the issue. In order to select the best corrective action, financial analyses (payback and life cycle cost) should be conducted on the top two or three options before determining and carrying out the optimum fix. These corrective actions obviously depend on the established root cause. Here are a few scenarios to consider:

- If the root cause of the problem is that the pump is oversized, causing the pump to operate for long periods of time at low flow rates in the suction recirculation region, the corrective action with the lowest initial cost might be to just trim the impeller. However, in all probability, there are also other actions that can be taken to reduce or eliminate the suction recirculation (see WW, June 2010). This could also be an opportunity to justify a variable speed drive (VSD). Adding a VSD would also lower the suction energy and further improve overall reliability and efficiency.

- If the root cause is how the pumps are operated - especially if there is more than one pump operating in parallel - guidance may have to be developed to insure that the minimum number of pumps are operated at any one time to insure that the pumps operate close to their best efficiency flow points (see WW, Nov. 2008).

- If the root cause is that the bearings are not being properly lubricated (see WW, Feb. 2008), changing to an oil mist system - although more expensive - might produce the lowest life cycle costs. Also, slower speeds or operation closer to the BEP will also reduce the bearing loads and increase the life of the bearings (see WW, April 2008, Dec. 2007).

- If the root cause is that the mechanical seal faces are experiencing dry or abrasive operation, a double seal might be in order. Of course the root cause of the mechanical seal failures might also be due to off-BEP operation or cavitation-caused vibration.

- If the root cause is the lack of a reliable preventive maintenance program (see WW, Dec. 2008), pump users may want to update maintenance procedures and consider an automated condition monitoring/fault-tolerant intelligent drive system (possibly including a VFD).

Conclusions

As can be seen from the above, if a pump fails or is in obvious distress, and the mean time between failure is low, it can be financially advantageous to perform a more thorough analysis of the problem and not just replace the broken parts in kind. If a user wants to cut operating costs and maximize mean time between pump failures, it may be well worth conducting a thorough, systematic troubleshooting of these pump failures and correcting the root causes - like a best-in-class pump user would do.

About the Author: Allan R. Budris, P.E., is an independent consulting engineer who specializes in training, failure analysis, troubleshooting, reliability, efficiency audits, and litigation support on pumps and pumping systems. He can be contacted via email at [email protected].